Composite feedforward control type hysteresis control system

A feedforward control and hysteresis control technology, applied in control/regulating systems, instruments, regulating electrical variables, etc. Amplifier error characteristics affect control circuit performance, increase in manufacturing cost of DC-DC converters, etc., achieve good regulation and high-speed transient response characteristics, eliminate phase delay problems, and improve cost and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

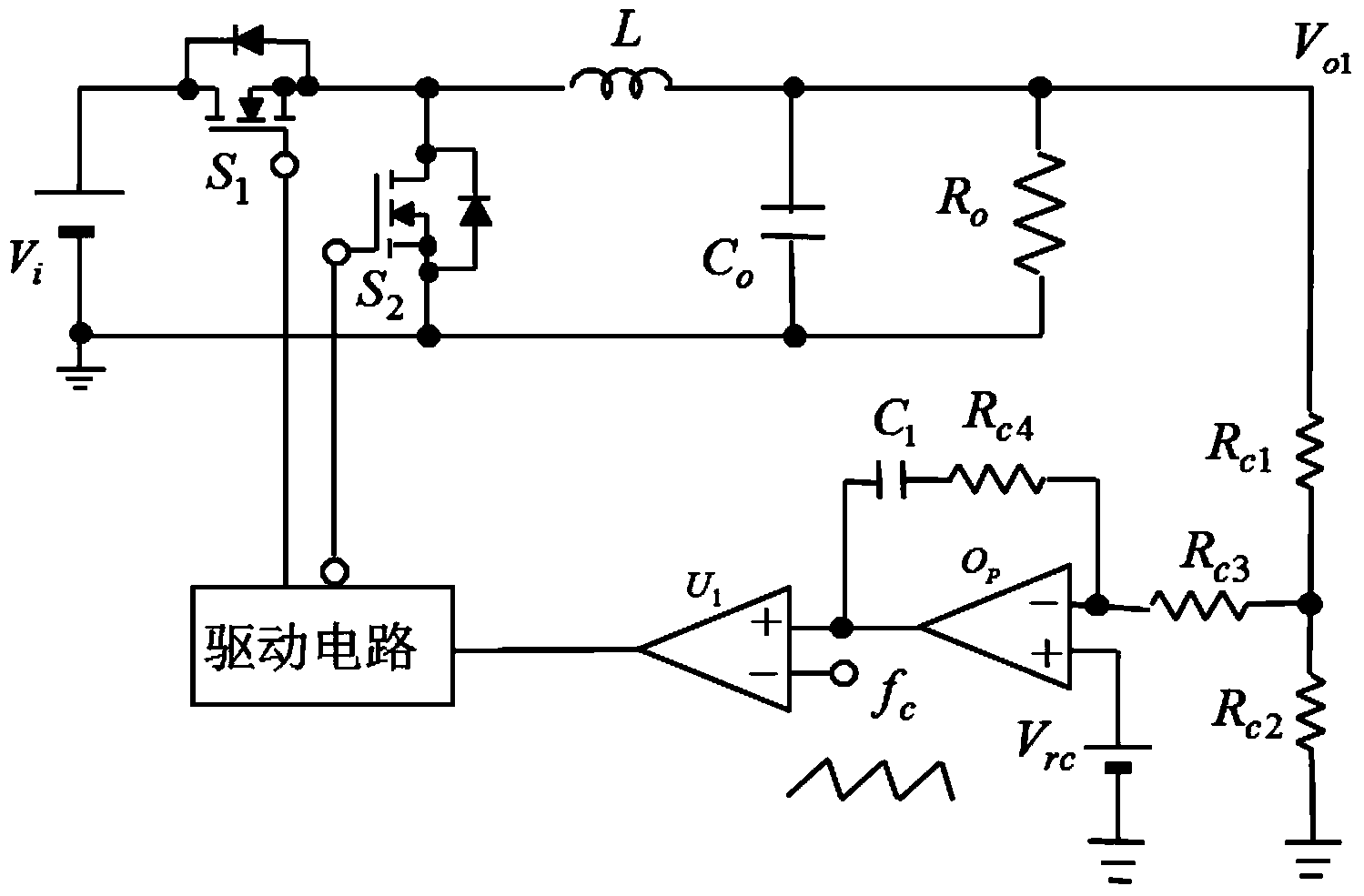

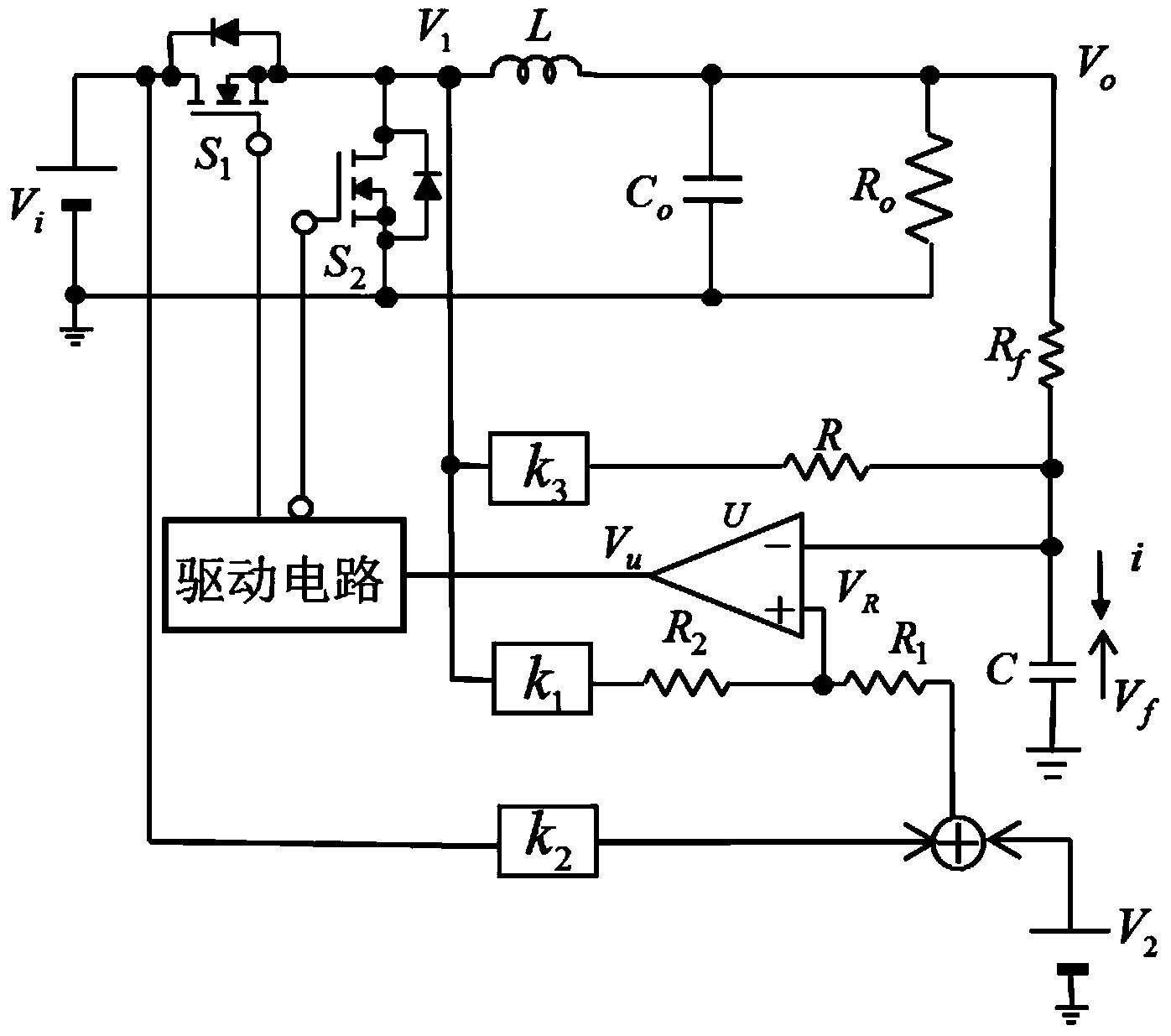

[0039] Such as figure 2As shown, a compound feedforward control type hysteresis control system, including sequentially connected input voltage V i , main switching tube S 1 and S 2 , filter circuit and load R o , the main switching tube is connected with a drive circuit, and the filter circuit includes a filter inductor L and a filter capacitor C o , the hysteresis control system also includes a feedback bypass, an adjustment capacitor C, a hysteresis comparison circuit and a feedforward circuit, and the feedback bypass is respectively connected to the main switching tube and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com