Multilayered circuit board structure with buried element and manufacturing method

A multi-layer circuit and embedded component technology, which is applied in the direction of multi-layer circuit manufacturing, printed circuit connected with non-printed electrical components, printed circuit assembled with electrical components, etc., can solve complicated steps, errors, and laser offset Position and other problems, to achieve the effect of improving the tolerance range of alignment errors, saving manufacturing process steps, and simplifying production and manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

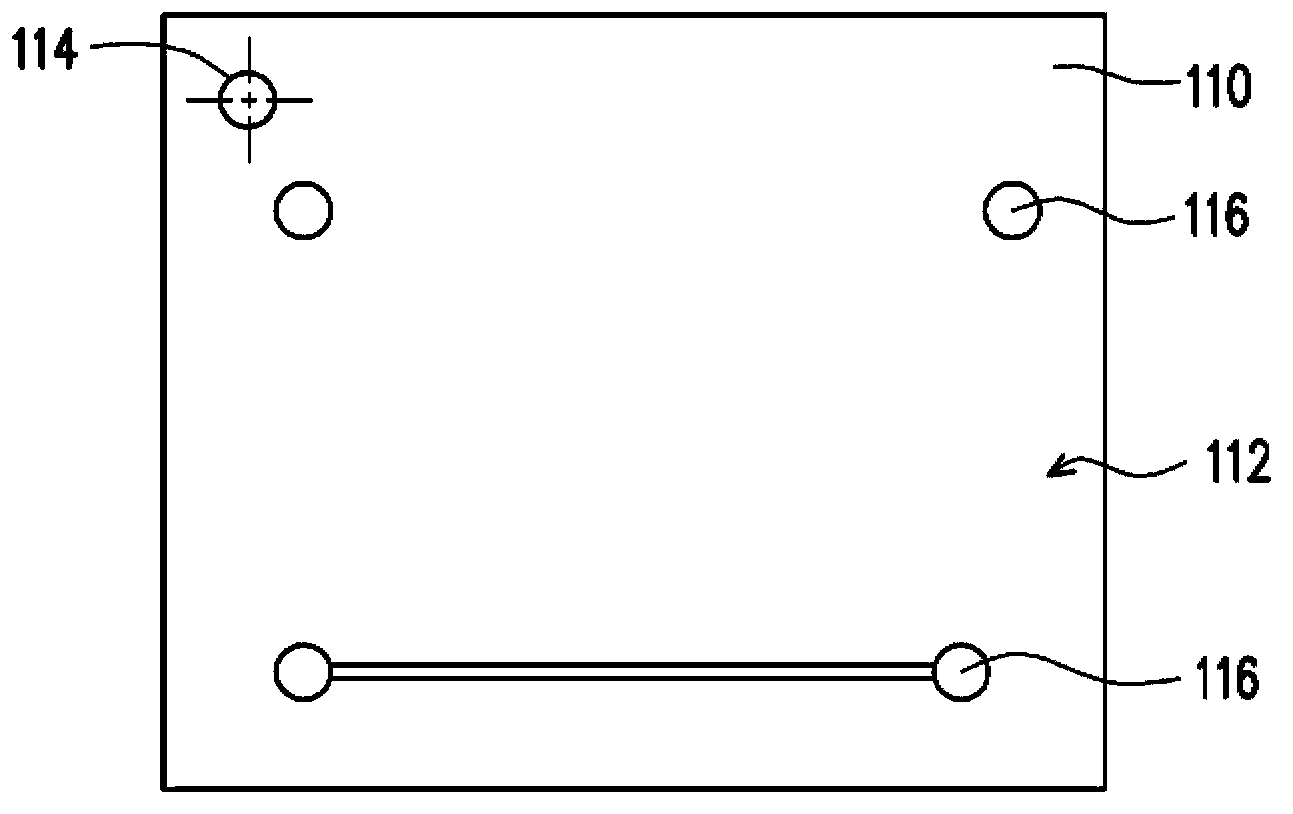

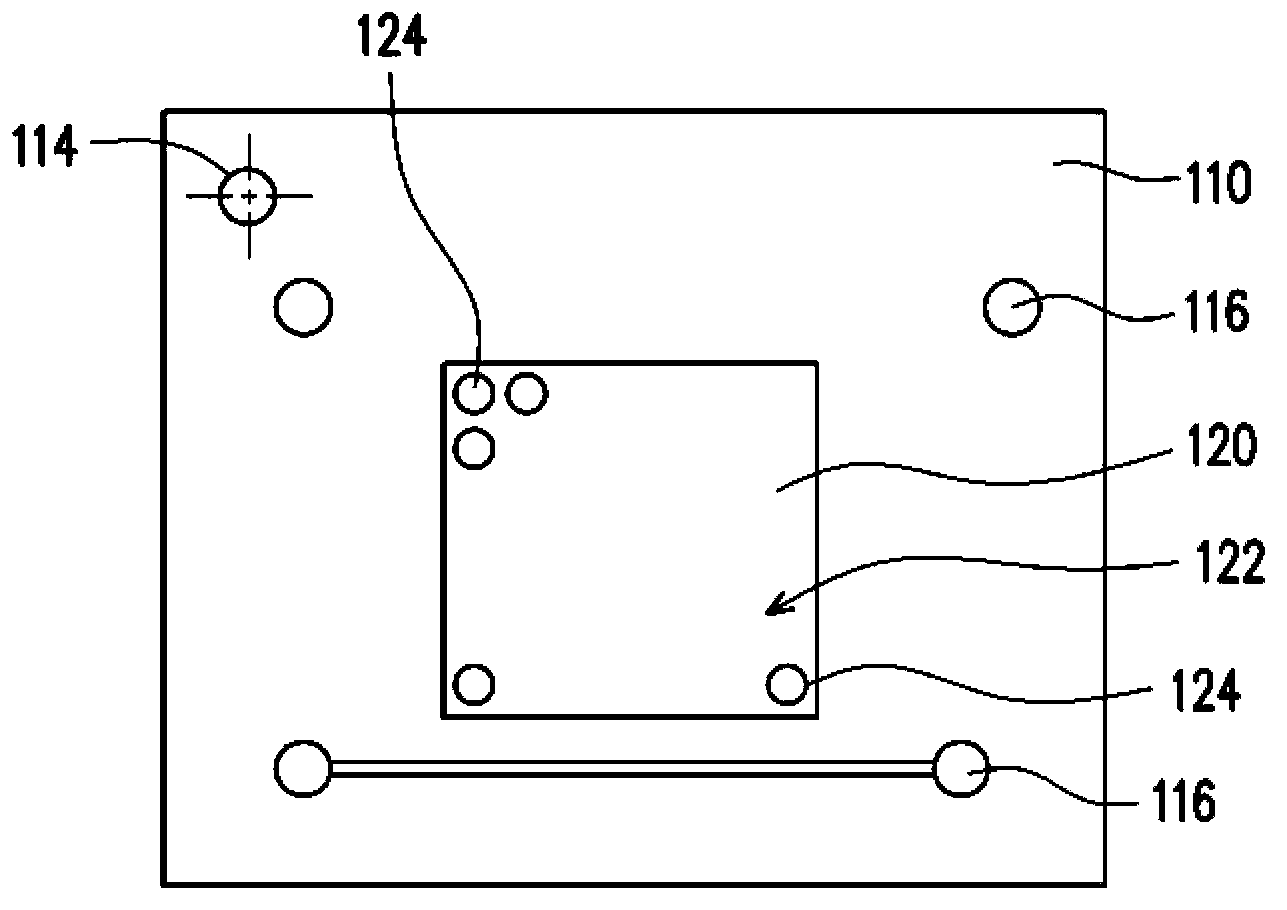

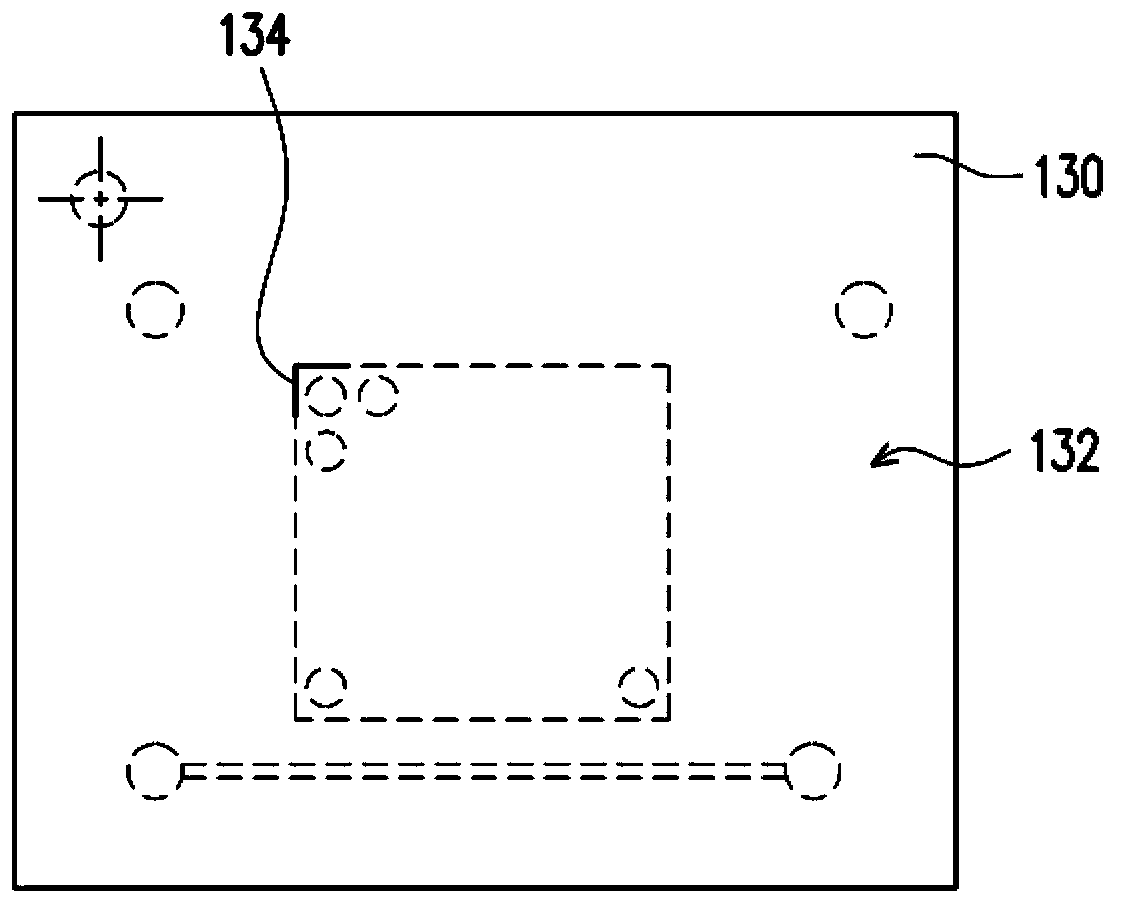

[0050] Figure 1A to Figure 1G It is a schematic top view of the manufacturing process of a multilayer circuit board structure with embedded components according to an embodiment of the present invention. According to the manufacturing method of the multilayer circuit board structure with embedded components in this embodiment, first, please refer to Figure 1A , providing a substrate 110 having a first surface 112 and at least one first alignment mark 114 on the first surface 112 , wherein the first surface 112 of the substrate 110 further has a plurality of first pads 116 . Next, please refer to Figure 1B , disposing at least one semiconductor element 120 (shown as one) on the substrate 110 , wherein the upper surface 122 of the semiconductor element 120 has a plurality of second pads 124 . In this embodiment, the semiconductor element 120 may be an active element, a passive element, a chip scale package (Chip Scale Package, CSP), a circuit board or any combination thereof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com