Method and system for methane fermentation processing of sludge using hydrothermal reactions

A methane fermentation and hydrothermal reaction technology, applied in water/sludge/sewage treatment, biological sludge treatment, water treatment parameter control, etc., can solve problems such as not reaching economic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

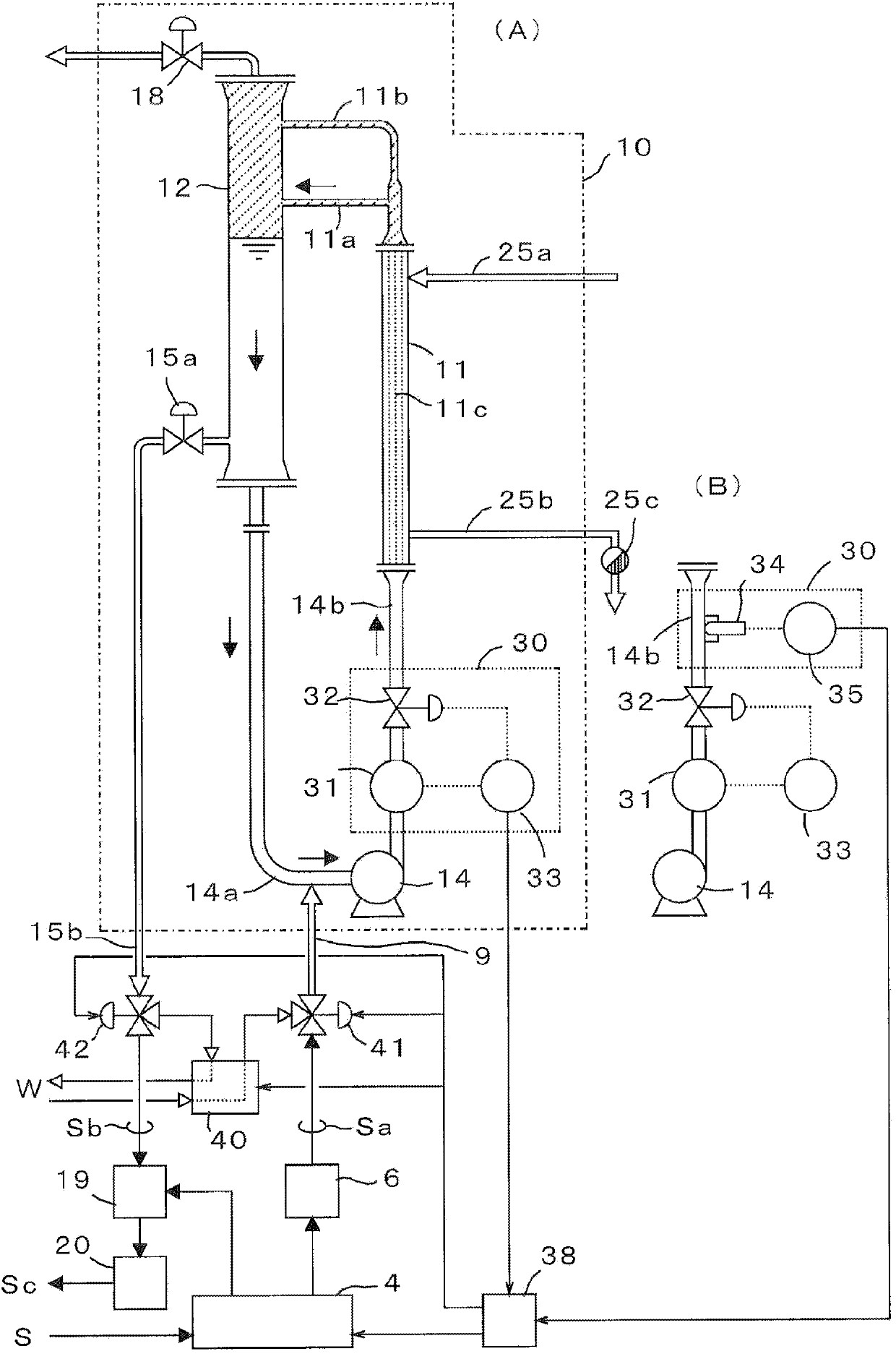

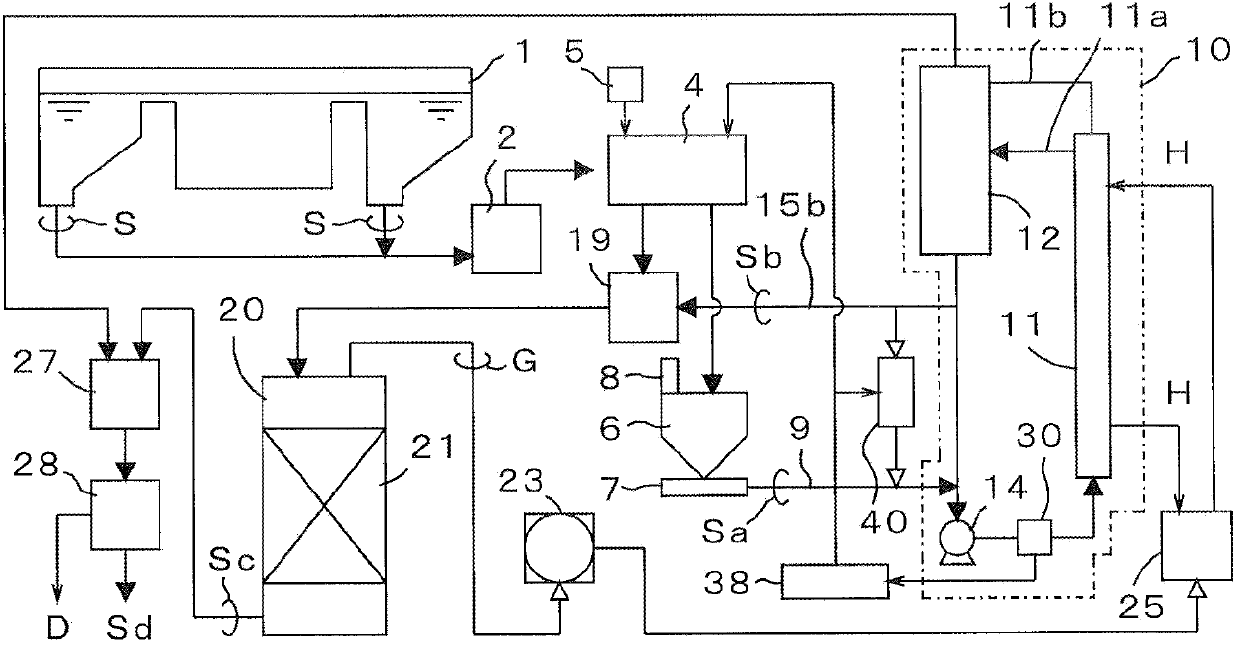

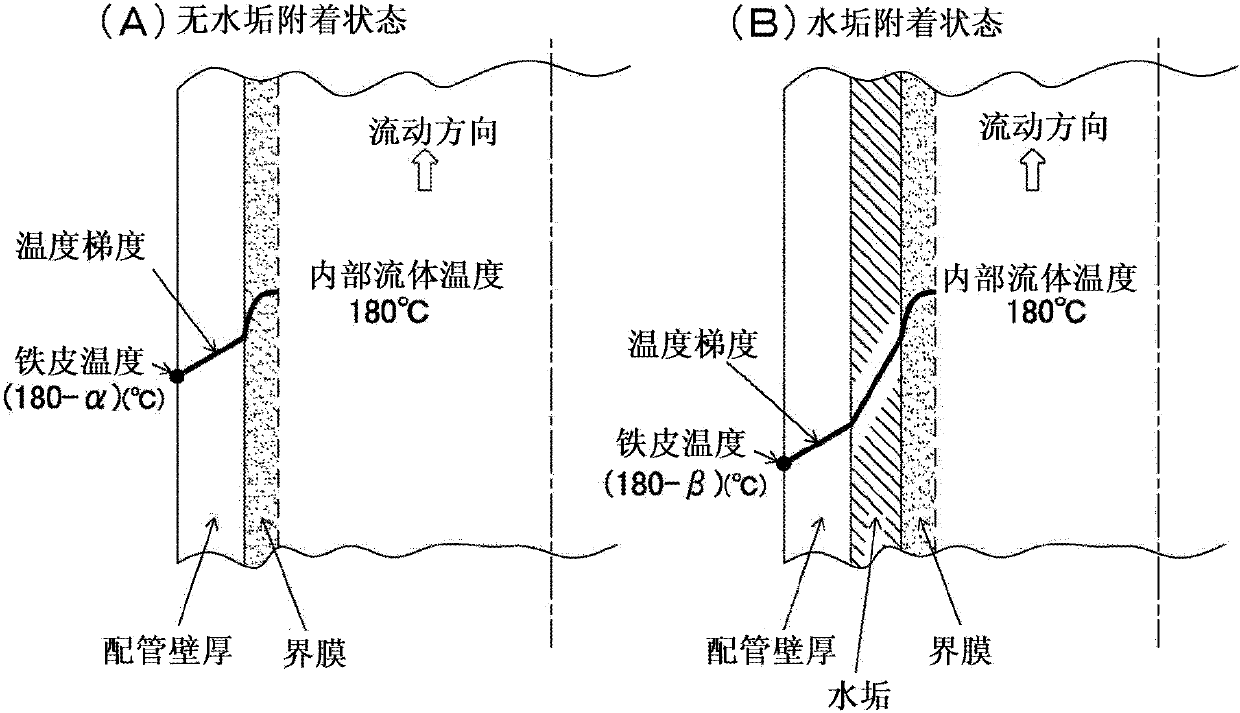

[0055] figure 1 and figure 2 The embodiment is provided with the cleaning device 40 that carries out water displacement cleaning or chemical cleaning to the interior of the circulation path 14a, 14b of the hydrothermal reaction device 10, and can drive cleaning according to the detection of the scale fixation status by means of the above-mentioned fixation status detection device 30 device 40. As mentioned above, in the circulation type hydrothermal reaction device 10, it is necessary to periodically clean the scale fixed in the circulation path, but by driving the cleaning device 40 according to the detection of the scale fixation state by the detection device 30, it is not necessary to stop and open The need for cleaning of the reaction device 10 can be judged, and the reaction device 10 can be cleaned at an optimal timing.

[0056] The cleaning device 40 of the illustrated example has an injection path connected to the feed path 9 of the hydrothermal reaction device 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com