Single cream cheese and preparation method thereof

A cream and cheese technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of uneven texture of finished products, microbial contamination, easy water separation, etc., and achieve the characteristics of cream with strong flavor, stable quality, and easy to smear good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

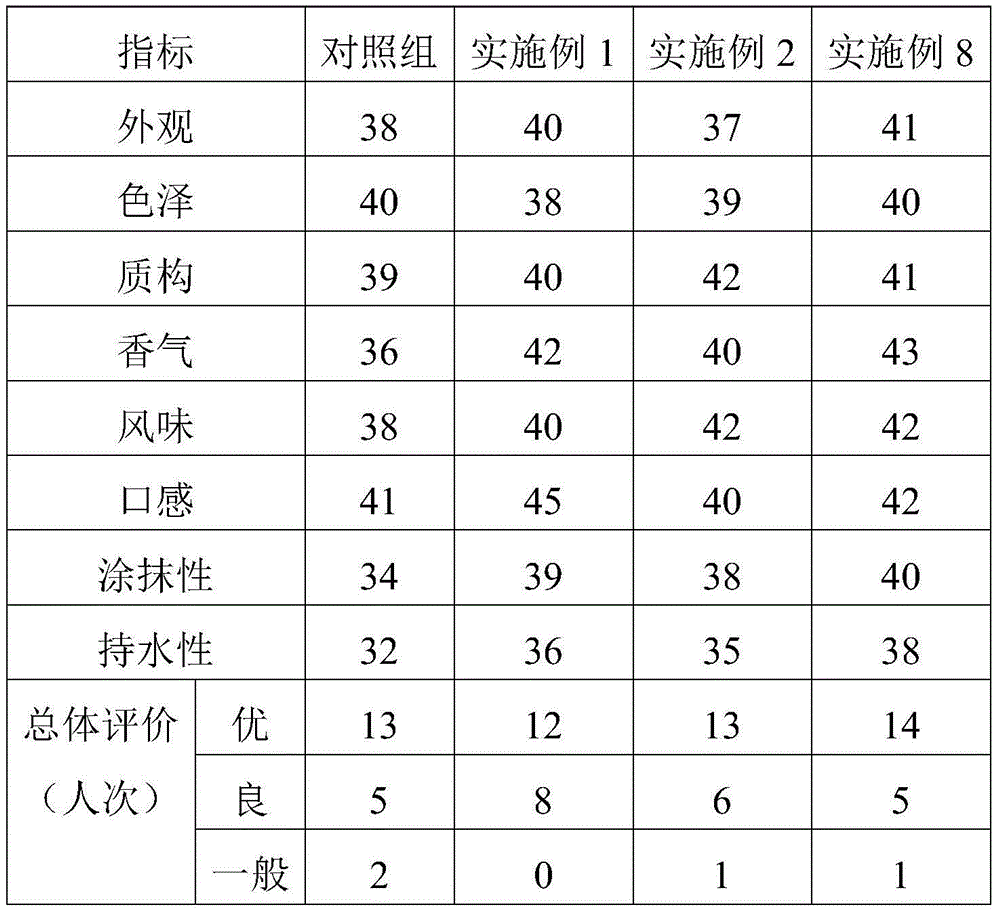

Examples

Embodiment 1

[0040] S1. (1) Skim milk (fat content 0.1%) is heat-treated at 88°C for 10 minutes, then cooled to 32°C, and added to starter R704; after mixing evenly, ferment at 33°C until the pH reaches 4.7 to obtain curd; Cut the curd, discharge the whey at 20°C by hanging bag method, collect the whey, and complete the whey discharge when the total solid of the curd reaches 45%, and obtain the cheese curd;

[0041] (2) Adjust the collected whey with tartaric acid to pH 4.6, boil while stirring, collect the flocculent whey clots floating on the surface, and drain the water;

[0042] (3) Pasteurize the cream at 90°C for 15s, then cool to 22°C, add starter R704; after mixing evenly, ferment at 22°C until the acid value is 15 mg / g to obtain sour cream;

[0043] S2, put 55% cheese curd, 40% sour cream by weight, 2% whey curd, 2% whole milk powder, 0.3% locust bean gum and 0.7% salt into the melting pot , the stirring speed is 900rpm, the jacket is heated to 80°C, kept for 5min, homogenized wh...

Embodiment 2

[0045] S1. (1) Skim milk (fat content 0.3%) is heat-treated at 95°C for 5 minutes, then cooled to 30°C, and then added to starter MM100; after mixing evenly, ferment at 35°C until the pH reaches 4.5 to obtain curd; Cut the curd, filter the whey at 22°C with a membrane, collect the whey, and complete the whey discharge when the total solids of the curd reach 50%, and obtain the cheese curd;

[0046] (2) Adjust the collected whey to pH 4.6 with citric acid, boil while stirring, collect the flocculent whey clots floating on the surface, and drain the water;

[0047] (3) Pasteurize the cream at 85°C for 60s, then cool to 25°C, add starter MM100; mix well and ferment at 25°C until the acid value is 14 mg / g to obtain sour cream;

[0048] S2, with 50% cheese curd, 44% sour cream by weight, 2% whey curd, 3% skimmed milk powder, 0.4% xanthan gum, 0.58% salt and 0.02% lactic acid chain ball Put the mycocin into the melting pot, stir at 1000rpm, heat the jacket to 82°C, keep it for 4min...

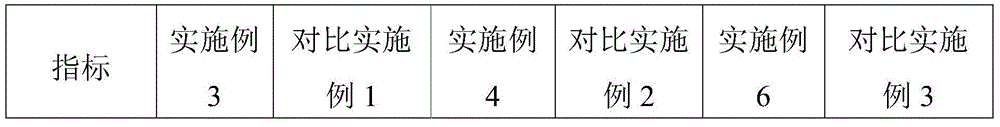

Embodiment 3

[0050] S1. (1) Skim milk (fat content 0.2%) is heat-treated at 90°C for 8 minutes, then cooled to 30°C, and then added to the starter LL-50; after mixing evenly, ferment at 30°C until the pH reaches 4.6 to obtain coagulation Milk; cut the curd, filter the whey at 25°C with a membrane, collect the whey, and complete the whey discharge when the total solid of the curd reaches 48%, and obtain the cheese curd;

[0051] (2) Adjust the collected whey to pH 4.6 with gluconolactone, boil while stirring, collect the flocculent whey clots floating on the surface, and drain the water;

[0052] (3) Pasteurize the cream at 90°C for 15s, then cool to 20°C, add starter LL-50; mix well and ferment at 20°C until the acid value is 13 mg / g to obtain sour cream;

[0053] S2, with 54% cheese curd, 40% sour cream by weight, 4% whey curd, 1% milk protein powder, 0.1% locust bean gum, 0.4% salt and 0.5% sorbic acid Put the potassium into the melting pot, stir at 700rpm, heat the jacket to 80°C, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com