Multi-component alloy water purification mesh material and water purification filter element made from same

A technology of multi-element alloy and water purification filter, which is applied in the field of water purification filter to achieve the effect of inhibiting the reproduction of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: In this implementation mode, a multi-component alloy mesh water purification material is a mesh material woven by alloy wire or alloy strip;

[0023] The alloy wire is composed of 0-2.0% trace elements, 0-0.5% impurities and Cu as the balance by weight percentage, wherein the trace elements are Ag, Zn, Al, Bi, Sb, Fe, Mg , Sn, Pb, Ni, Mn, Co, Cr, Be, Cd, Zr, As, S, Si, P and O, or a mixture of several of them, or the alloy wire is composed of 0 by weight percentage ~25.0% of trace elements, 0~2.0% of impurities, 1.0%~65.0% of Zn and the balance of Cu, wherein the trace elements are Ag, Al, Bi, Sb, Fe, Mg, Sn, Pb, One or a mixture of Ni, Mn, Co, Cr, Be, Cd, Zr, As, S, Si, P and O;

[0024] The alloy strip is composed of 0-2.0% trace elements, 0-0.5% impurities and Cu as the balance by weight percentage, wherein the trace elements are Ag, Zn, Al, Bi, Sb, Fe, Mg , Sn, Pb, Ni, Mn, Co, Cr, Be, Cd, Zr, As, S, Si, P and O, or a mixture of seve...

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that: the hole specification of the mesh material is 1 mesh to 2500 mesh; the wire diameter of the alloy wire is 0.002 mm to 3.0 mm; The alloy strip has a width of 0.002 mm to 5.0 mm and a thickness of 0.002 mm to 1 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

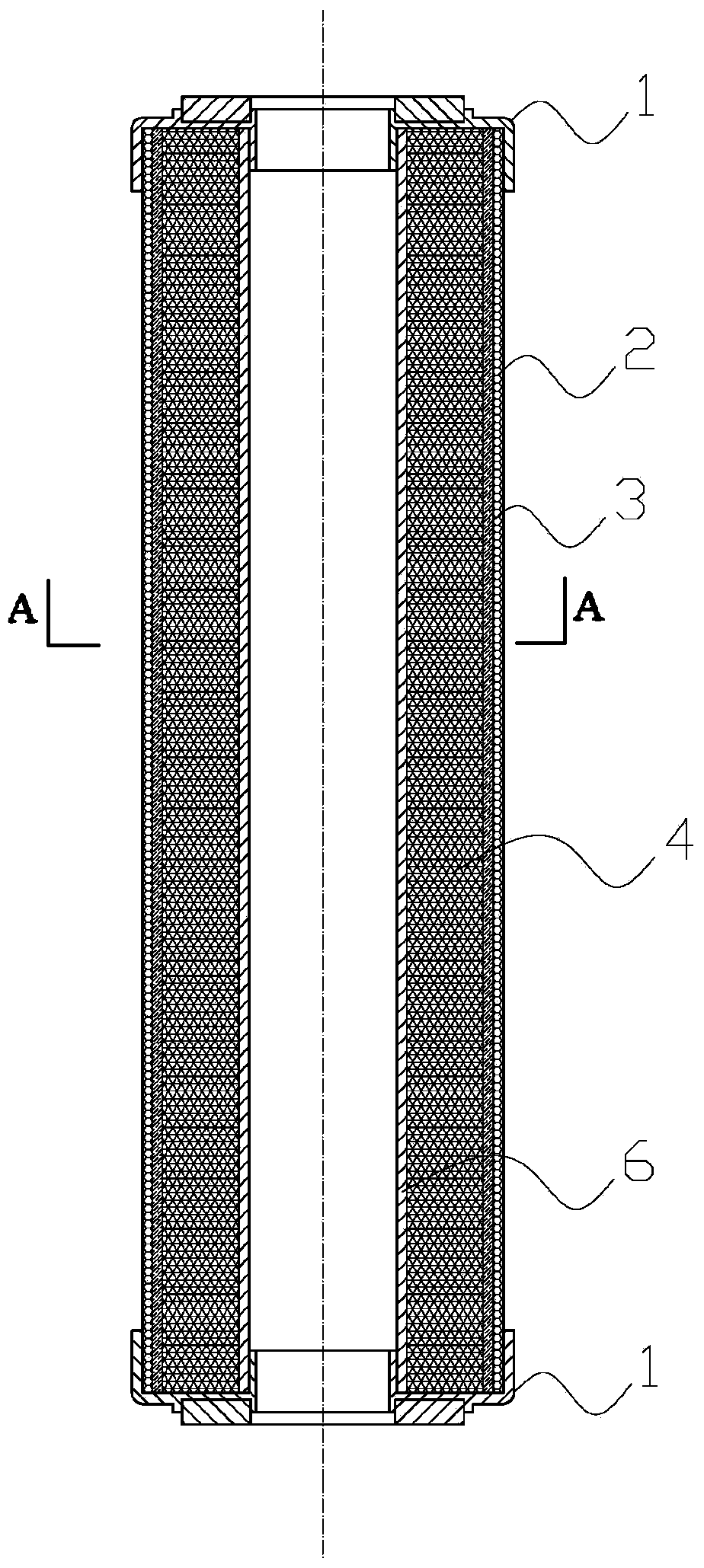

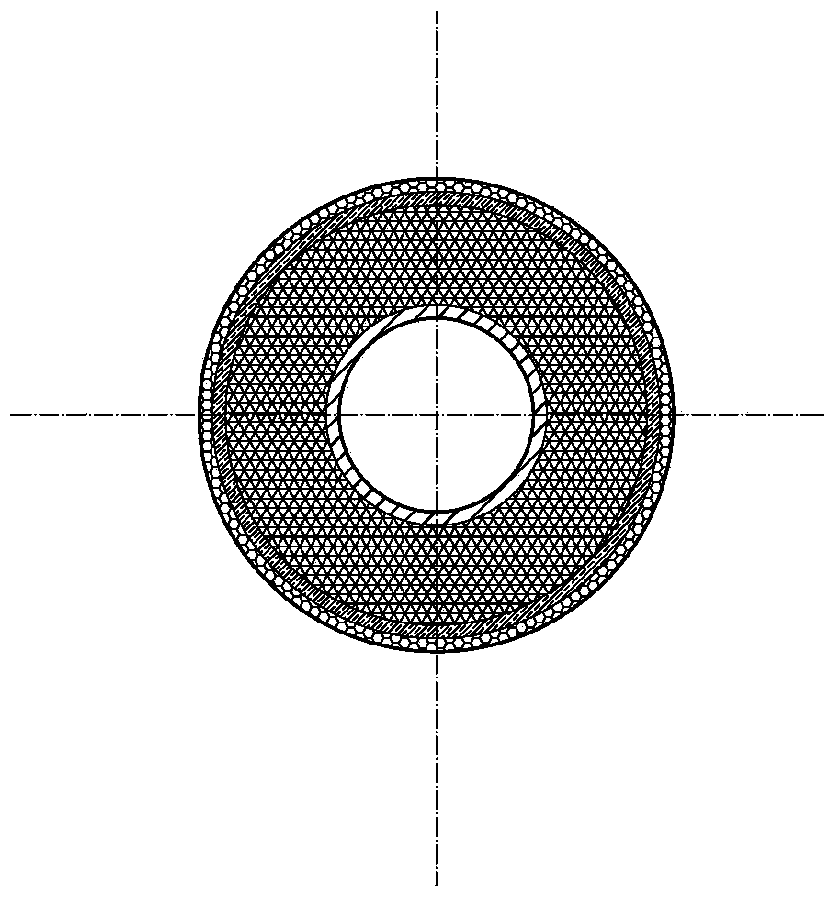

[0030] Embodiment 3: The water purification filter element made of a multi-element alloy mesh water purification material in Embodiment 1 is made of a multi-element alloy mesh water purification material alone, or is made of one or more layers of multi-element alloy mesh water purifiers. The water material is composited with one or more layers of other water purification materials; the other water purification materials are granular activated carbon, compressed activated carbon, sintered activated carbon, activated carbon fiber, ceramics, membrane material, fiber felt, filter cloth, fiber activated carbon or medical stone.

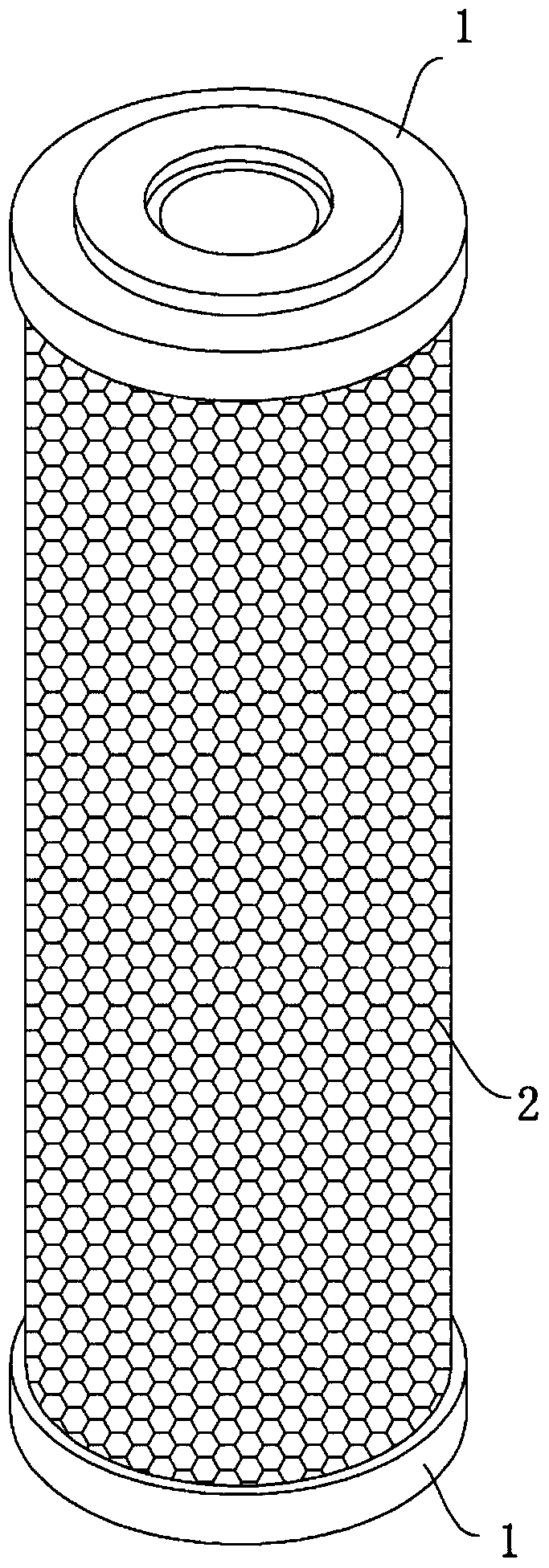

[0031] figure 1 It is a schematic diagram of the appearance of the filter element described in this embodiment, figure 1 Among them, 1 is the end cover, and 2 is the outer protective net.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com