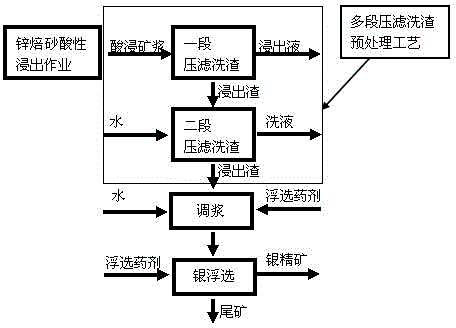

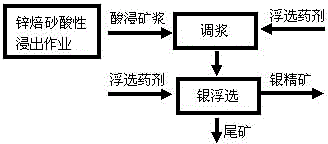

Silver floatation production process method for zinc hydrometallurgy acid leaching pulp

A technology of hydrometallurgy and production technology, applied in flotation, solid separation, etc., to achieve the effects of simplifying the process, reducing costs, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

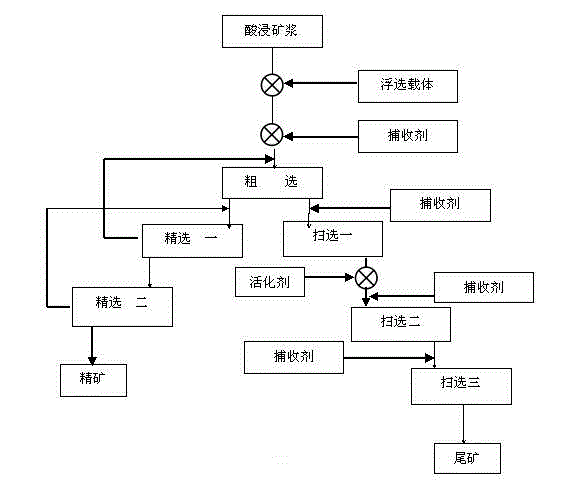

Embodiment 1

[0058] A zinc-acid leaching ore pulp in a hydro-smelting process that has not been filtered and washed has a pulp concentration of 30%, a zinc ion concentration of 185g / l, a pulp pH of 2.6, a pulp temperature of 70°C, and a silver content of 466 g / ton. Get 2500 milliliters of this ore pulp respectively, move in 3 liters of single tank flotation machines, according to image 3 As shown in the technological process, the flotation carrier with an amount of 5 kg / ton of calcined sand is added to the roughing slurry tank, the activator of 40 grams / ton of calcined sand is added to the stirring tank of Sweep 2, and the collector of 120 grams / ton of calcined sand is added to the rough selection. Ton calcine, add collector 60 g / ton calcine in sweep 1 and sweep 2 respectively, add collector 30 g / t calcine in sweep 3, the results of closed-circuit flotation test are shown in Table 1.

[0059]

example 2

[0061] A zinc-acid leaching ore pulp in a hydro-smelting process that has not been filtered and washed has a pulp concentration of 31%, a zinc ion concentration of 193g / l, a pulp pH of 2.8, a pulp temperature of 69°C, and a silver content of 397 g / ton. Get 2500 milliliters of this ore pulp respectively, move in 3 liters of single tank flotation machines, according to image 3 As shown in the technological process, the flotation carrier with an amount of 4 kg / ton of calcined sand is added to the roughing slurry tank, the activator of 35 grams / ton of calcined sand is added to the stirring tank of Sweep 2, and the collector of 100 grams / ton of calcined sand is added to the rough selection. Ton calcine, add collector 50 g / ton calcine in sweep 1 and sweep 2 respectively, add collector 25 g / t calcine in sweep 3, the results of closed-circuit flotation test are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com