Horizontal spiral discharge settling centrifuge

A settling centrifuge, horizontal screw technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of worn blades, increased equipment operating costs and maintenance costs, increased thickness of solid slag piles, etc., to achieve Effects of preventing solid phase accumulation, reducing maintenance and operating costs, and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

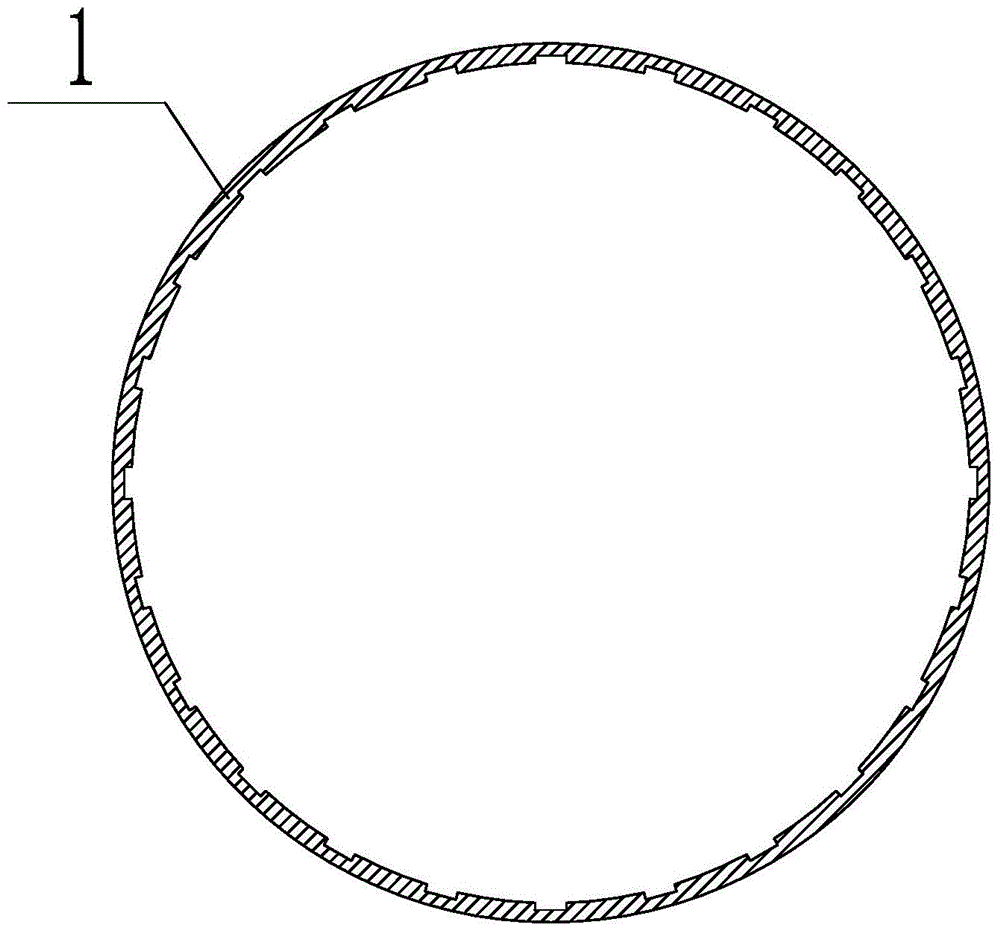

[0017] Such as figure 1 with figure 2 As shown, a horizontal screw unloading decanter centrifuge of the present invention comprises a drum 1 and a screw 2, the screw 2 has blades 21 arranged in a spiral, and the outer cover of the drum 1 is provided with a shell 3, and the shell One end of the housing 3 is provided with a feed port 31 connected to the inner cavity of the screw rod 2, and the lower end of the housing 3 is provided with a liquid discharge port 32 at one end close to the feed port 31, and a slag discharge port 33 is provided at the other end. The inner wall of the drum 1 is provided with at least 20 grooves along the circumference. By setting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com