Closed type extrusion forging technology of complete fiber single-throw crankshaft forge piece

An all-fiber, closed-type technology, which is applied in metal plastic forming process and closed-type extrusion forging, can solve the problems of reducing production efficiency, increasing mold costs and processing procedures, and achieving high production efficiency, low cost, and material utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

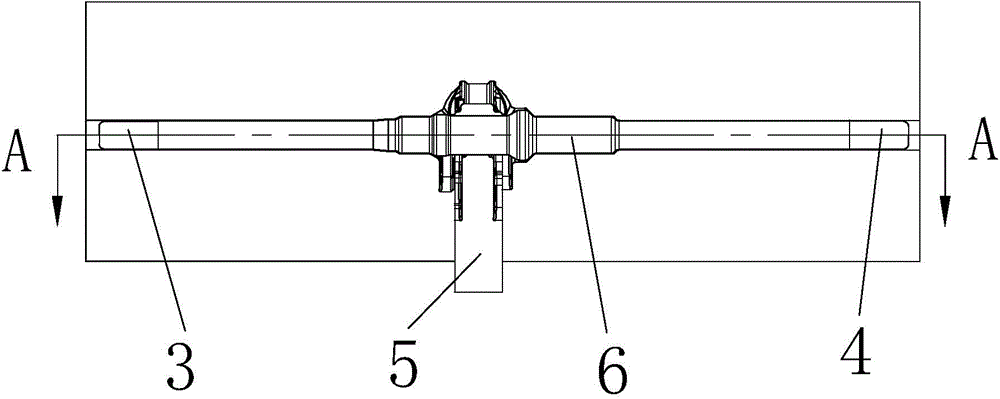

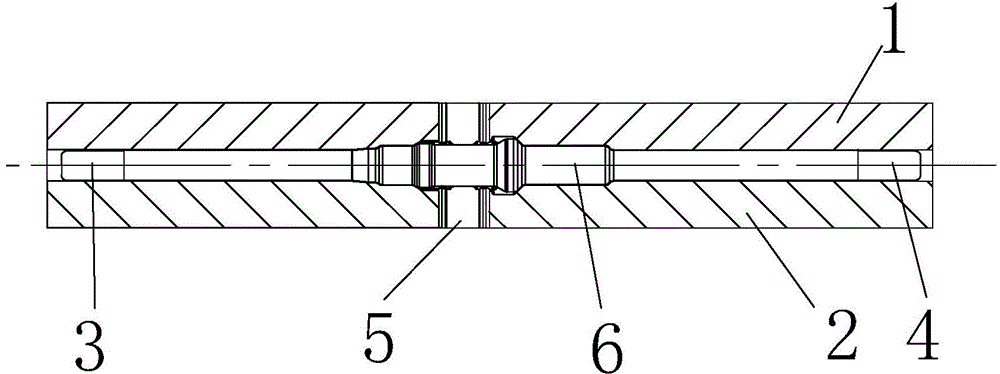

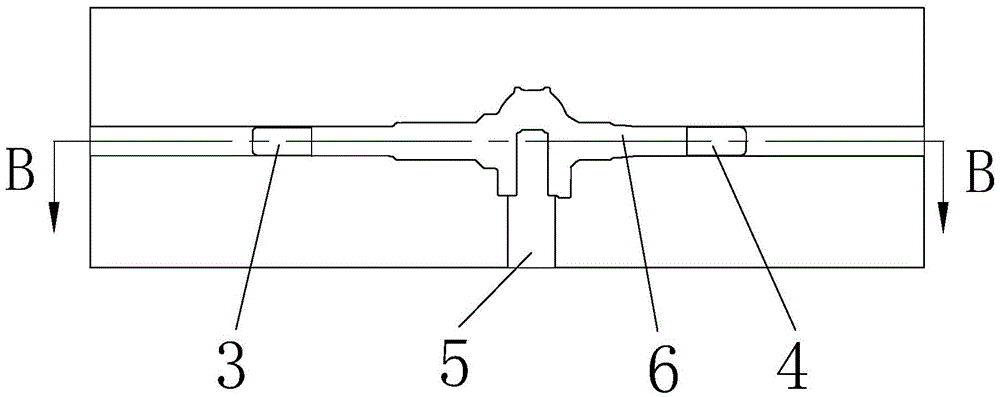

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] A closed-type extrusion forging process for a single-crank all-fiber crankshaft forging, comprising the following process steps:

[0022] Step (1) Intermediate frequency induction heating: heat the selected round billet to the initial forging temperature in an intermediate frequency induction heating furnace.

[0023] Step (2) Cross-wedge rolling billet: the heated round billet is rolled into a blank through the cross-wedge rolling die in the cross-wedge rolling mill, and the shaft parts at both ends are formed. The round billet is under the action of the forging cross-rolling die , radial compression, axial extension, realize the material volume distribution in the axial direction within one revolution of the mold. The above two steps are the same as the first two steps of the "method for forming a single crankshaft forging" with the patent number 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com