Titanate chelate for single-component dealcoholized room temperature vulcanized silicone rubber and preparation method thereof

A room temperature vulcanization and dealcoholization technology, applied in the direction of titanium organic compounds, etc., can solve the problems that the production process has not yet been published, and the titanate chelate is not clear, so as to avoid the viscosity peak, the process is easy to realize, and the production process is easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

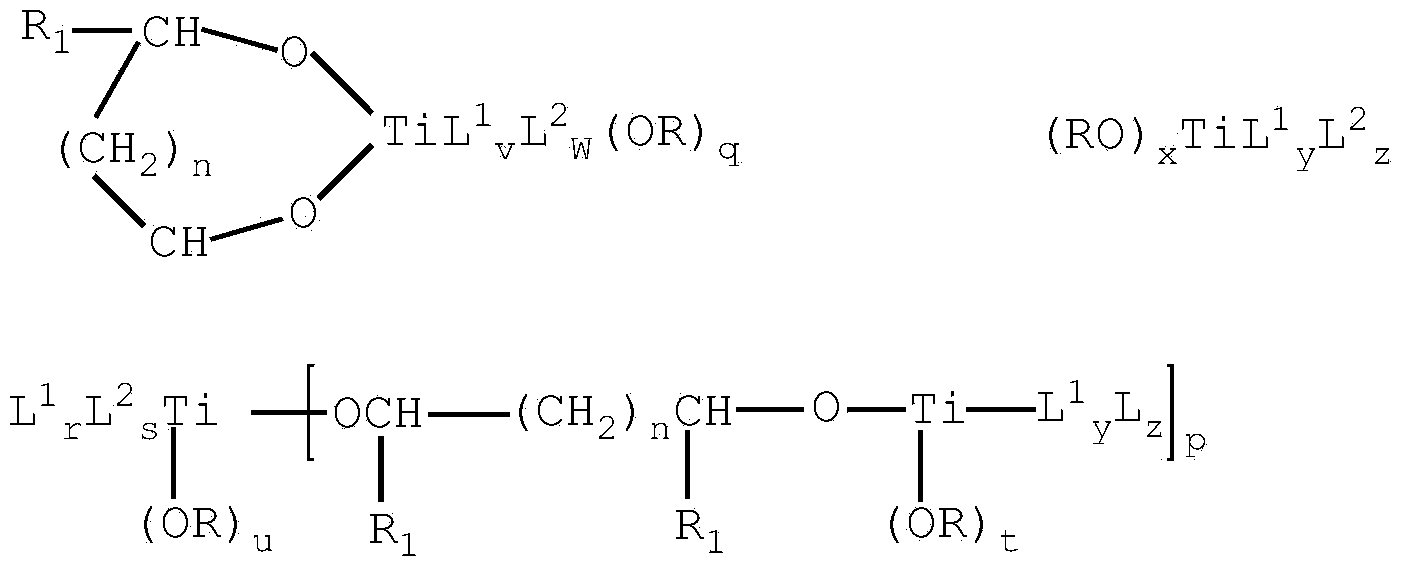

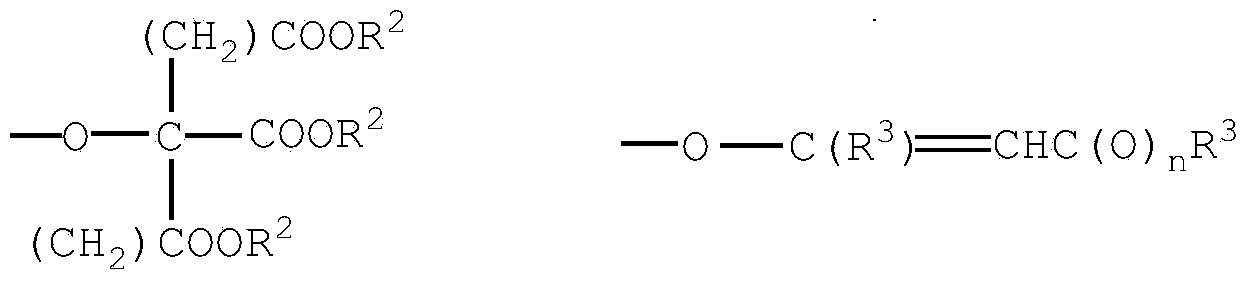

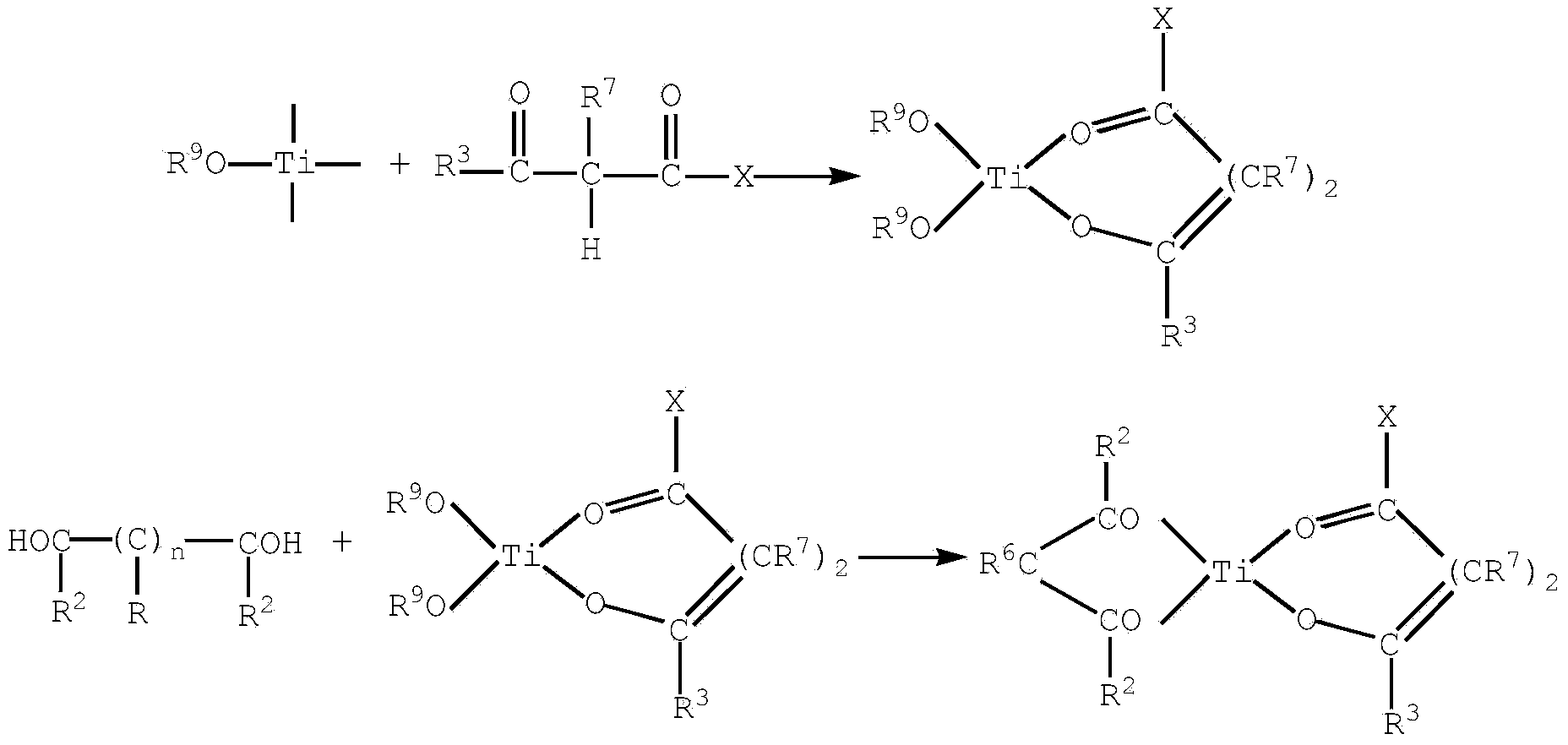

[0033] A titanate chelate compound for one-component dealcoholized room temperature vulcanized silicone rubber, using isopropyl titanate, ethyl acetoacetate and 1,3-propanediol as raw materials, and the final product is 1,3-propanediol Oxybis(ethyl acetoacetate) titanate, the chemical reaction equation is:

[0034]

[0035] and

[0036]

Embodiment 2

[0038] A preparation method for a one-component dealcoholized room temperature vulcanized silicone rubber titanate chelate, comprising the following steps:

[0039] (1) Add 1000g of tetraisopropyl titanate into a dry and clean three-necked bottle of 3000ml, and drop 111.6g of ethyl acetoacetate into the three-necked bottle evenly, stir for 2h; then heat to 40 with an oil bath or a constant temperature heater ℃;

[0040] (2) First remove isopropanol under normal pressure, then remove under reduced pressure until no liquid drops drip out, add 267g of 1,3-isopropanol after cooling, and stir for 3 hours;

[0041] (3) The temperature of the oil bath is raised to 80°C-90°C, and the by-product isopropanol is removed for 6-7h after the vacuum degree is greater than 650 Torr;

[0042] (4) The obtained product is sealed into a glass bottle.

[0043] The obtained product was used to produce GD406, GD407RTV-1.

Embodiment 3

[0045] A preparation method for a one-component dealcoholized room temperature vulcanized silicone rubber titanate chelate, comprising the following steps:

[0046] (1) Add 1000g of tetraisopropyl titanate to a dry and clean 3000ml three-necked bottle, and drop 111.6g of ethyl acetoacetate into the three-necked bottle evenly, and stir for 2 hours; then heat it with an oil bath or a constant temperature heater until 40°C;

[0047] (2) First remove isopropanol under normal pressure, then remove under reduced pressure until no liquid drops drip out, add 267g of 1,3-isopropanol after cooling, and stir for 3 hours;

[0048] (3) The temperature of the oil bath is raised to about 140 degrees, and the by-product isopropanol is removed for 6-7 hours under a vacuum degree > 650 Torr;

[0049] (4) The obtained product is sealed into a glass bottle.

[0050] The resulting product is used as a catalyst for the production of GD414.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com