High-concentration SBR (styrene butadiene rubber) modified emulsified asphalt and preparation method thereof

An emulsified asphalt, high-concentration technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of high-concentration SBR modified emulsified asphalt, etc. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

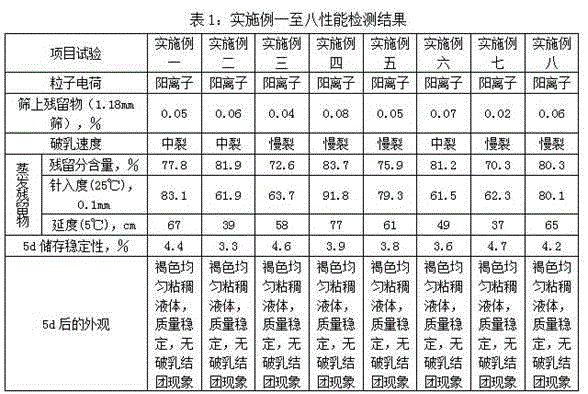

Examples

Embodiment 1

[0038] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0039] Asphalt: 750 grams, Vincent Yi heavy mixed crude oil propane asphalt produced by Maoming Petrochemical, the penetration is greater than 50, and the dynamic viscosity at 60°C is 136.

[0040] SBR latex: 40 grams, the SBR-40 of Zibo Qiaolong Company, its solid concentration is 40%.

[0041] Emulsifier: 23 grams, FS-C01 cationic asphalt emulsifier produced by Fuster Chemical Company.

[0042] Water: 187 grams, clear and transparent tap water without impurities.

[0043] First add the emulsifier and SBR latex into the water and stir evenly to form a soap solution and heat it to 65°C, and heat the asphalt to 140°C. Then add the hot soap solution into the emulsification equipment for circulation, then add hot asphalt while circulating and shearing, and the speed of adding the hot asphalt should be controlled so that th...

Embodiment 2

[0045] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0046]Asphalt: 780 grams, grade B road asphalt produced by Maoming Petrochemical Co., Ltd., with a penetration of more than 50 and a dynamic viscosity at 60° C. of 145.

[0047] SBR latex: 48 grams, 40 type styrene-butadiene latex of Shandong Xianyuan Chemical Technology Co., Ltd., its solid content concentration is 40%.

[0048] Emulsifier: 28 grams, JY-R2H cationic asphalt emulsifier produced by Jinyang Material Technology Company.

[0049] Water: 144 grams, clear and transparent tap water without impurities.

[0050] First add the emulsifier and SBR latex into the water and stir evenly to form a soap solution and heat it to 70°C, and heat the asphalt to 150°C. Then add the hot soap solution into the emulsification equipment for circulation, then add hot asphalt while circulating and shearing, and the speed of adding ...

Embodiment 3

[0052] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0053] Asphalt: 690 grams, sand-in-Kuwait mixed crude oil No. 70 A-grade road asphalt produced by Maoming Petrochemical, the penetration is greater than 50, and the dynamic viscosity at 60°C is 190.

[0054] SBR latex: 32 grams, the SBR-40 of Zibo Qiaolong Company, its solid concentration is 40%.

[0055] Emulsifier: 20 grams, JY-R4 cationic asphalt emulsifier produced by Jinyang Material Technology Co., Ltd.

[0056] Water: 258 grams, clear and transparent tap water without impurities.

[0057] First add the emulsifier and SBR latex into the water and stir evenly to form a soap solution and heat it to 60°C, and heat the asphalt to 130°C. Then add the hot soap solution into the emulsification equipment for circulation, then add hot asphalt while circulating and shearing, and the speed of adding the hot asphalt should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com