Low-temperature composite activated black dye and application thereof

A technology of reactive dyes and reactive blacks, used in organic dyes, dyeing methods, textiles and papermaking, etc., to save energy, reduce hydrolysis rate, and improve absolute color fixing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

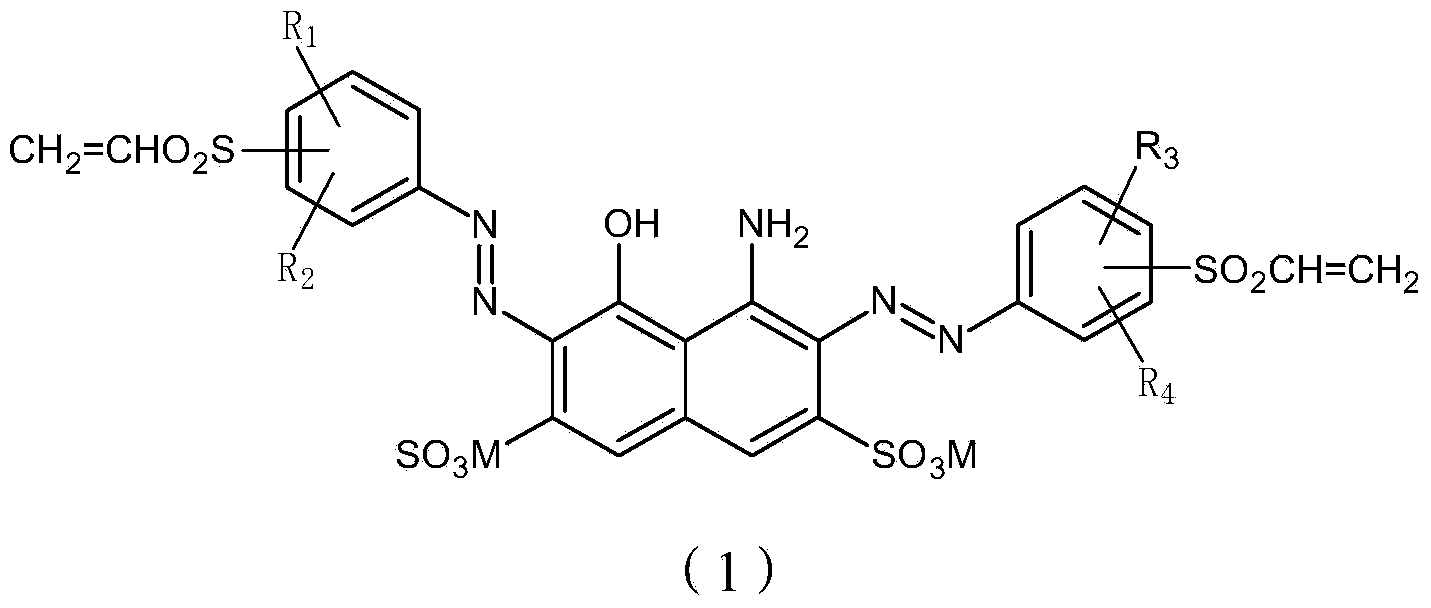

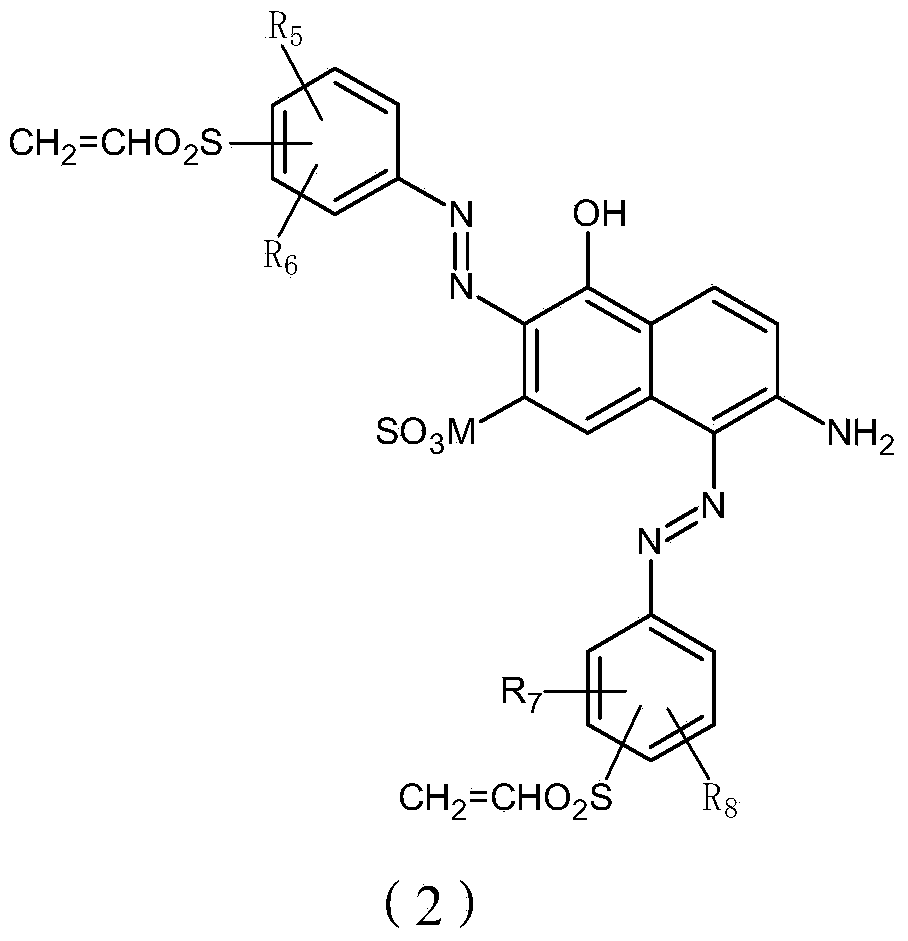

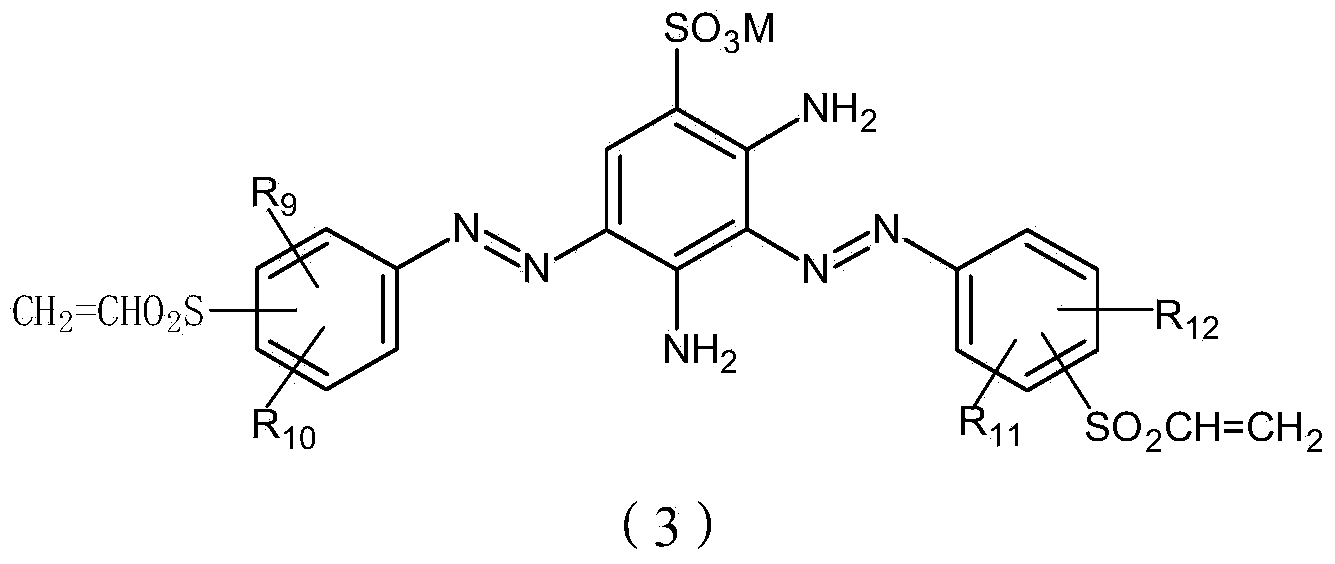

[0032] A low-temperature composite reactive black dye, composed of reactive dye A shown in formula (1), reactive dye B shown in formula (2), reactive dye C shown in formula (3), and reactive dye C shown in formula (4) Reactive dye D, reactive dye E shown in formula (5) and auxiliary agents are compounded. The contents of reactive dyes A, B, C, D, E and auxiliary agents in every 100g of low-temperature composite reactive black dye are shown in Table 1.

[0033]

[0034]

[0035]

[0036] From formula (1) to formula (5) -SO 2 CH=CH 2 Both by -SO 2 CH 2 CH 2 OSO 3 It is obtained by degreasing Na and soda ash, and the composition of substituents is shown in Table 2.

[0037] In the composite reactive black dye composition of the present invention, the compounding method of each reactive dye is not particularly limited, can adopt: manufacture each reactive dye respectively, then carry out the method of compounding; The reaction liquid that contains each reactive dye g...

Embodiment 2

[0041] A low-temperature composite reactive black dye, composed of reactive dye A shown in formula (1), reactive dye B shown in formula (2), reactive dye C shown in formula (3), and reactive dye C shown in formula (4) Reactive dye D, reactive dye E shown in formula (5) and auxiliary agents are compounded. The contents of reactive dyes A, B, C, D, E and auxiliary agents in every 100g of low-temperature composite reactive black dye are shown in Table 1. From formula (1) to formula (5) -SO 2 CH=CH 2 Both by -SO 2 CH 2 CH 2 OSO 3 It is obtained by degreasing Na and soda ash, and the composition of substituents is shown in Table 2.

[0042] Application of a low-temperature composite reactive black dye for dyeing pure cotton black. The specific dyeing steps are as follows: bath ratio 1:30, adding 10% of the dye and sodium hexametaphosphate by fabric weight at room temperature, the amount of sodium hexametaphosphate 100g / L, run for 8min, heat up to 50°C at a heating rate of 3°C...

Embodiment 3~5

[0044] The compositions of the low-temperature composite reactive black dyes of Examples 3 to 5 are shown in Table 1, and the compositions of the substituents in formula (1) to formula (5) are shown in Table 2.

[0045] Table 1: The proportions of each component of the low-temperature composite reactive black dyes of Examples 1 to 5

[0046]

[0047] Table 2: Composition of substituents in Examples 1 to 5

[0048]

[0049] R 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com