Light oil recovery device of distillation system

A recovery device and distillation system technology, applied in hydrocarbon distillation, petroleum industry, etc., can solve the problems of heavy environmental pollution, loss of light oil, increased cost consumption, etc., to reduce environmental pollution, avoid excessive loss, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

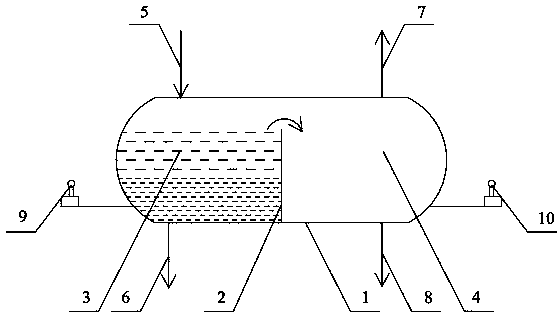

[0010] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the distillation system light oil recovery device, the device includes a tank body 1, the tank body 1 is divided into I zone 3 and II zone 4 by vertically arranged partitions 2, and I zone 3 The top is connected to the condensed oil gas inlet pipeline 5, the bottom is connected to the ammonia water discharge pipeline 6, the top of II zone 4 is connected to the non-condensable gas discharge pipeline 7, and the bottom is connected to the light oil discharge pipeline 8.

[0011] The I zone 3 is equipped with a liquid level gauge one 9, and the II zone 4 is equipped with a liquid level gauge two 10, the liquid level gauge one 9 indicates the ammonia liquid level, and the liquid level gauge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com