Method for obtaining ferritic heat-resisting steel with the characteristic of austenite structure

A ferritic and heat-resistant steel technology, applied in the field of heat-resistant steel, can solve the problems of high alloy content and high cost, and achieve the effects of less diffusion channels, inhibition of coarsening rate, and increase of service temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of the ferritic heat-resistant steel is shown in Table 1. The heat-resistant steel was immediately quenched to room temperature after being kept at 1100°C for 60 minutes. Then temper at 780°C for 3 hours and air cool to room temperature. Example 1 is a traditional heat treatment system, in order to compare with the large deformation + heat treatment process of the present invention in Examples 2 and 3.

Embodiment 2

[0026] The composition of the ferritic heat-resistant steel is shown in Table 1. The heat-resistant steel is processed into a cylindrical sample of Φ8×15mm, and the large deformation + heat treatment process experiment is carried out on the Gleeble3800 thermal simulation testing machine. The steps are: / s heating to 1100°C, holding for 90min; then, cooling at 10°C / s to 600°C, holding for 10s, with deformation rate as 1s -1 Compression deformation is carried out, and the deformation amount is 70%. After the deformation is completed, it is quenched to room temperature immediately. Then temper at 750°C for 2 hours and air cool to room temperature.

Embodiment 3

[0028] The composition of the ferritic heat-resistant steel is shown in Table 1. The heat-resistant steel is processed into a cylindrical sample of Φ8×15mm, and the large deformation + heat treatment process experiment is carried out on the Gleeble3800 thermal simulation testing machine. The steps are: / s heating to 1150°C, holding for 40min; then, cooling at 10°C / s to 700°C, holding for 5s, with deformation rate as 1s -1 Compression deformation is carried out, and the deformation amount is 80%. After the deformation is completed, it is quenched to room temperature immediately. Then temper at 700°C for 4 hours and air cool to room temperature.

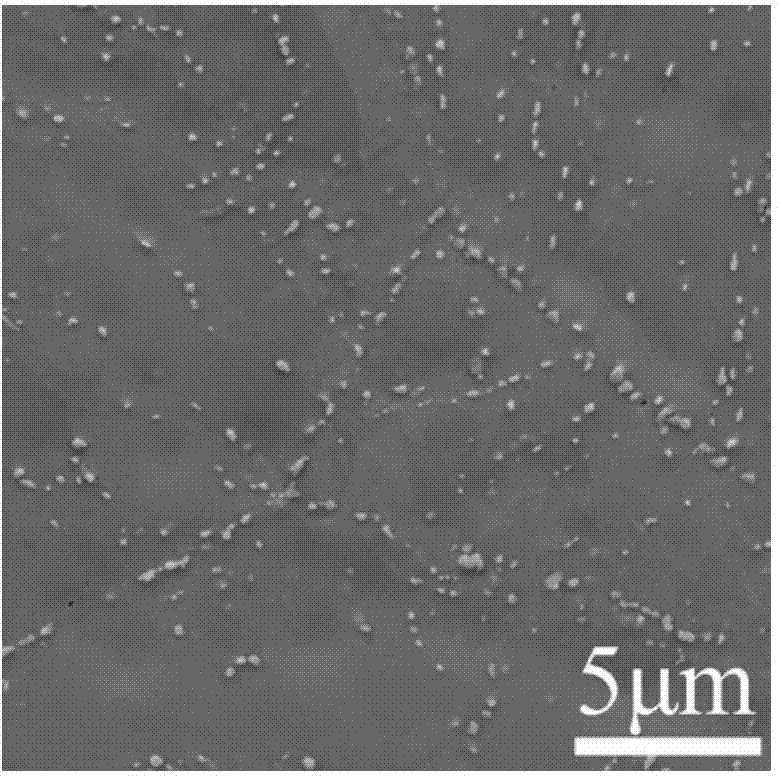

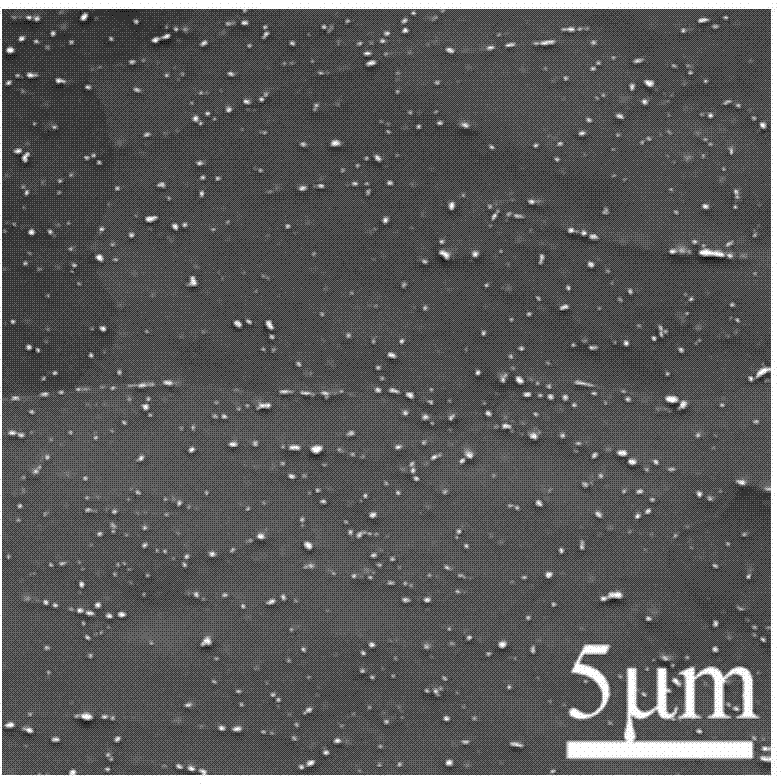

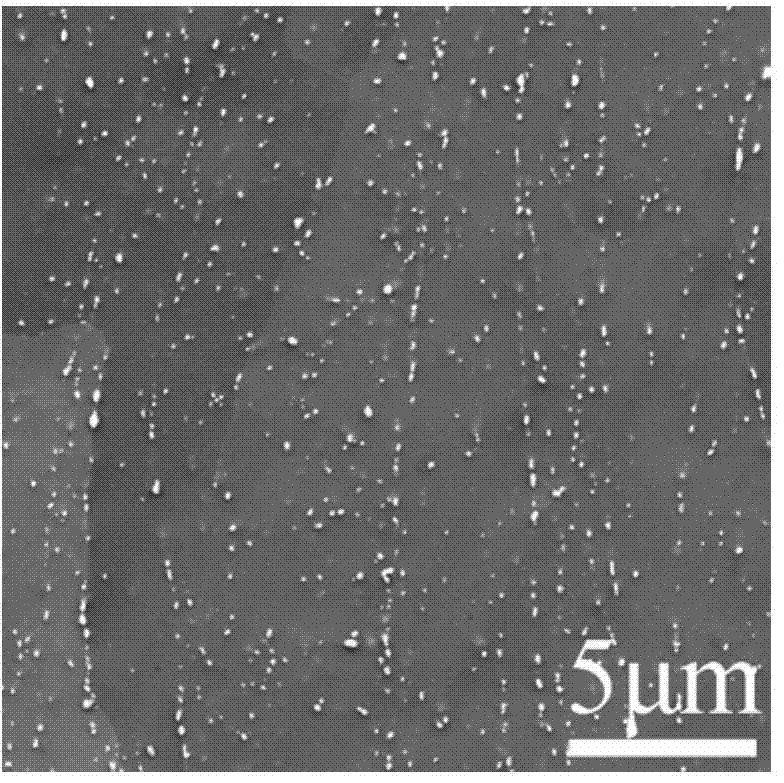

[0029] What embodiment 1 used is the traditional heat treatment process, as a comparison with the large deformation + heat treatment process of the present invention. What embodiment 2 and 3 used is the large deformation+heat treatment process of the present invention. The sample after the above heat treatment was analyzed by SEM and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com