A grating cooling device for positioning detection of stepping heating furnace

A technology for positioning detection and cooling device, applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems of combustion fan surge, high cost of compressed air consumption, high cost of spare parts, improve equipment service life, ensure heat treatment performance, Ensure proper positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

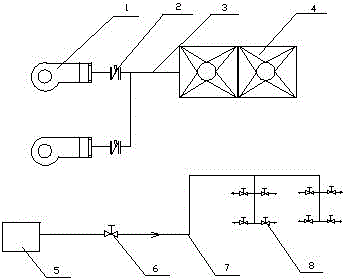

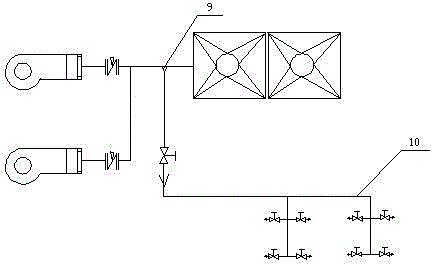

[0040] The present invention is a transformation of the cooling device of the grating detection system of the walking heating furnace. The air supply device of the air compressor and the combustion-supporting fan of the walking heating furnace injecting wind into the air heat exchanger are two sets of irrelevant devices, such as figure 1 As shown, the modified scheme is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com