Alloy material for aerospace field and manufacturing method thereof

An alloy material, aerospace technology, applied in the field of alloy material, aerospace, can solve the problem of reducing beryllium, performance can not reach beryllium bronze and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

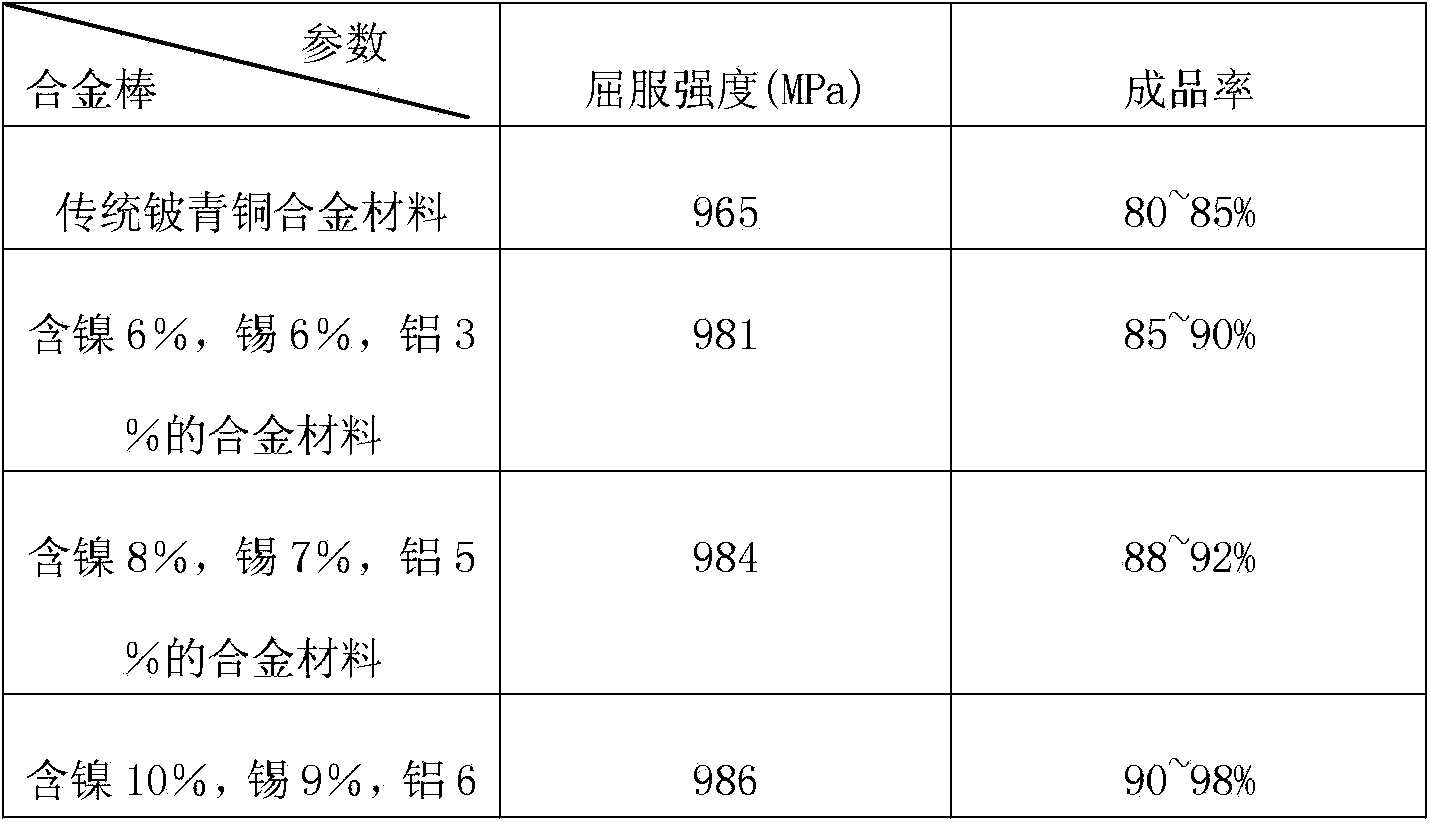

Embodiment 1

[0023] The alloy material used to replace beryllium copper in the aerospace field, the components of the alloy material are composed of 6% nickel, 6% tin, 3% aluminum, 0.1% manganese, 0.02% iron, and 84.88% copper.

[0024] First, make copper-nickel alloy: put electrolytic copper, nickel, and tin in a power frequency electric furnace according to the weight ratio, heat to 900-950 degrees, smelt for 1-1.5 hours, and keep warm to 850 degrees after complete melting, and the holding time is 0.5-1 hour; secondly, manufacture aluminum-tin alloy: put aluminum ingots and tin in a power frequency electric furnace according to the weight ratio, heat to 660-700 degrees, smelt for 1-1.5 hours, and keep warm to 550 degrees after completely melting, The holding time is 0.5-1 hour; after holding the heat for 0.5-1 hour, add the aluminum-tin alloy solution to the copper-nickel alloy, stir it with a graphite rod and then raise the temperature to 1000 degrees; after that, make manganese and iron...

Embodiment 2

[0027] The alloy material used to replace beryllium bronze in the aerospace field, the components of the alloy material are composed of 8% nickel, 7% tin, 5% aluminum, 0.3% manganese, 0.06% iron, and 79.64% copper.

[0028] First, make copper-nickel alloy: put electrolytic copper, nickel, and tin in a power frequency electric furnace according to the weight ratio, heat to 900-950 degrees, smelt for 1-1.5 hours, and keep warm to 850 degrees after complete melting, and the holding time is 0.5-1 hour; secondly, manufacture aluminum-tin alloy: put aluminum ingots and tin in a power frequency electric furnace according to the weight ratio, heat to 660-700 degrees, smelt for 1-1.5 hours, and keep warm to 550 degrees after completely melting, The holding time is 0.5-1 hour; after holding the heat for 0.5-1 hour, add the aluminum-tin alloy solution to the copper-nickel alloy, stir it with a graphite rod and then raise the temperature to 1000 degrees; after that, make manganese and iron...

Embodiment 3

[0031] The alloy material used to replace beryllium copper in the aerospace field, the components of the alloy material are composed of 10% nickel, 9% tin, 6% aluminum, 0.5% manganese, 0.1% iron, and 74.4% copper.

[0032] First, make copper-nickel alloy: put electrolytic copper, nickel, and tin in a power frequency electric furnace according to the weight ratio, heat to 900-950 degrees, smelt for 1-1.5 hours, and keep warm to 850 degrees after complete melting, and the holding time is 0.5-1 hour; secondly, manufacture aluminum-tin alloy: put aluminum ingots and tin in a power frequency electric furnace according to the weight ratio, heat to 660-700 degrees, smelt for 1-1.5 hours, and keep warm to 550 degrees after completely melting, The holding time is 0.5-1 hour; after holding the heat for 0.5-1 hour, add the aluminum-tin alloy solution to the copper-nickel alloy, stir it with a graphite rod and then raise the temperature to 1000 degrees; after that, make manganese and iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com