Waste heat reheating based compressed air energy-storage power-generation system

A compressed air energy storage and power generation system technology, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of large environmental impact, high geological conditions, high cost, etc., to save electricity costs, improve power generation efficiency, major The effect of practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

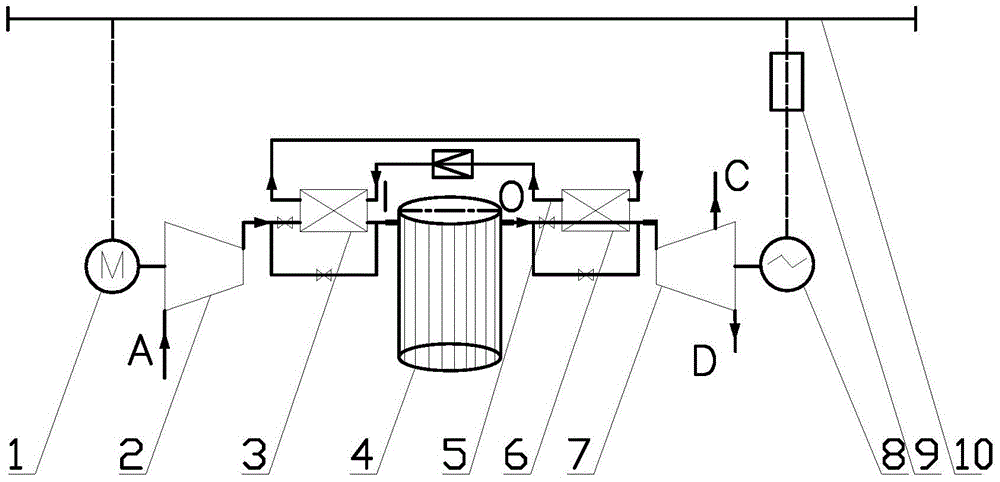

[0025] The compressed air energy storage power generation system based on waste heat reheating proposed by the present invention will be described in detail in conjunction with the drawings and embodiments.

[0026] Specific examples of the present invention are as follows. A compressed air energy storage power generation system based on waste heat reheating, including a compressor, an air energy storage cabinet, an air turbine, a generator, and a grid-connected system, and is characterized in that it also includes a set of waste heat phase change accumulators and A residual energy storage power generation device that supplements heat for the intake air of an air turbine, in which the suction port A of the compressor 2 is connected to the ambient air, and the exhaust port passes through the high-temperature air side of the phase change accumulator 3 and the air energy storage cabinet 4 is connected to the air inlet I, the air supply port O of the air energy storage cabinet 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com