Refrigeration cycling device

A circulation device and switching device technology, applied in the direction of reversible cycle compressors, refrigerators, refrigeration components, etc., can solve the problems of cost increase, gas refrigerant popularization restrictions, etc., to reduce expansion loss, simple structure, improve heating effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

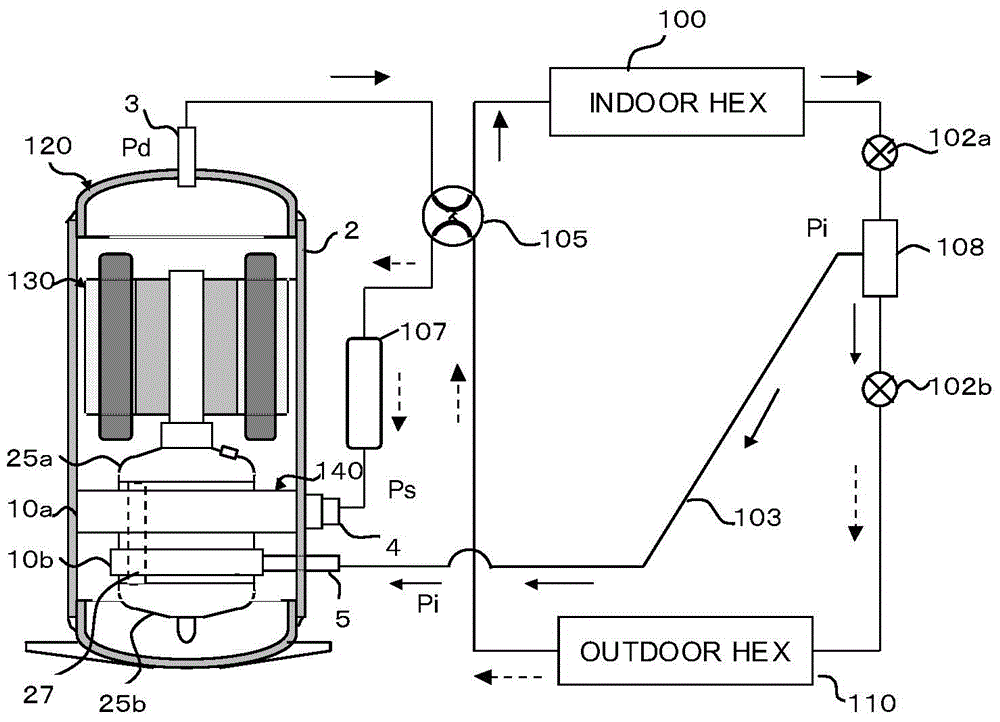

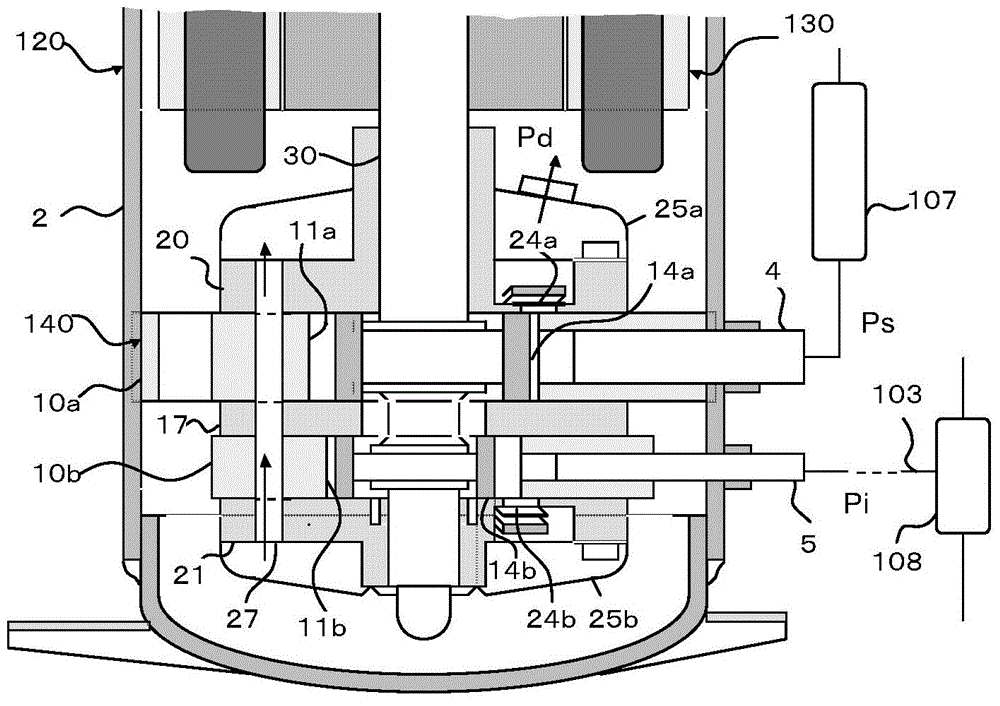

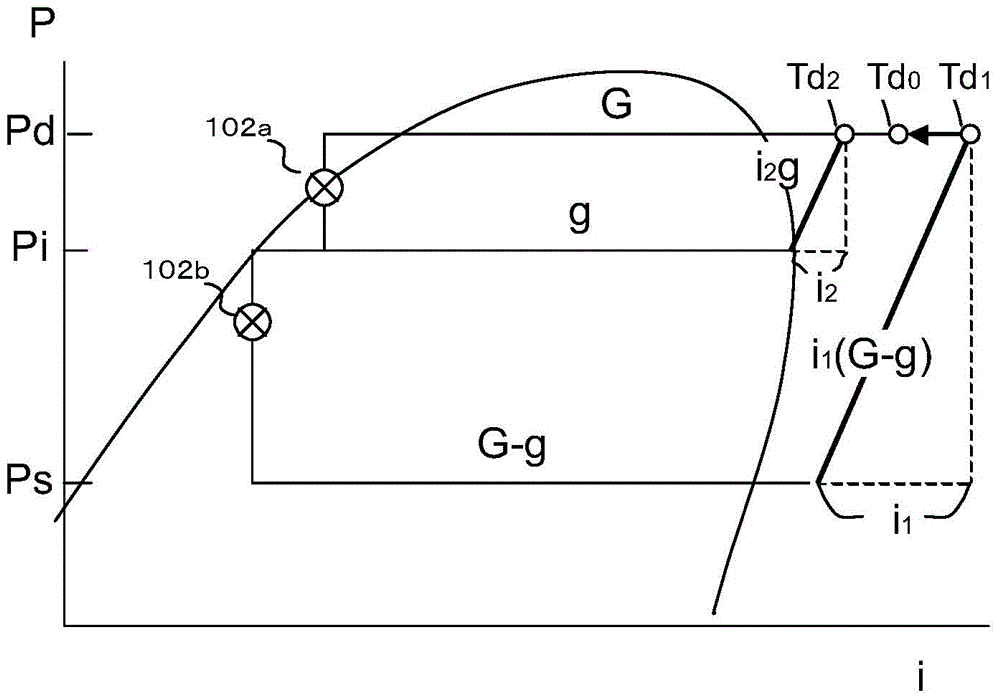

[0065] figure 1 The illustrated two-cylinder rotary compressor 120 is composed of an inverter-type motor unit 130 whose rotation speed can be changed on a hermetic casing 2 , and a compression element 140 arranged under the motor unit 130 . The high-pressure gas refrigerant (pressure Pd) discharged from the exhaust pipe 3 passes through the four-way valve 105 and becomes a condensed refrigerant in the indoor heat exchanger 100. After that, it is decompressed by the first expansion valve 102a, and the liquid refrigerant in the gas The liquid separator 108 is separated into medium-pressure gas refrigerant (pressure Pi) and liquid refrigerant. Therefore, the subcooling of the liquid refrigerant increases.

[0066] The liquid refrigerant continues to decompress through the second expansion valve 102b, and becomes a low-pressure gas refrigerant (pressure PS) in the outdoor heat exchanger 110, and then passes through the four-way valve 105 and the liquid reservoir 107 to connect wi...

Embodiment 2

[0080] From the viewpoint of the comfort and energy efficiency of the air conditioner for a year, there are product plans that do not use gas refrigerant injection in either the heating mode or the cooling mode, or there are products that suspend gas refrigerant injection during operation by selecting a mode planning. In addition, it is necessary to stop gas refrigerant injection during late night operation and dehumidification operation with a small air-conditioning load, or low-load operation after the room temperature stabilizes. As a means to achieve the purpose, Embodiment 2 is concerned with the technique of stopping or releasing the compression action of the second cylinder 10b having a small displacement.

[0081] First, design changes of the second embodiment as compared with the first embodiment will be described. Figure 4 What is shown is a cross-sectional view of the compression element 140, and embodiment 2 is equipped with a magnet 16 at the rear end of the sec...

Embodiment 3

[0085] Figure 9 The illustrated embodiment 3 is another application of the embodiment 2, which can be used when the injection of gas refrigerant is stopped no matter in the heating mode or the cooling mode. Embodiment 3 uses the rotary compressor 120 like Embodiment 2. Among them, the first two-way valve 106a and the second two-way valve 106b are omitted, and a three-way valve 116 is added.

[0086] Such as Figure 9 As shown, the three-way valve 116 is respectively connected to the medium-pressure suction pipe 5, the refrigerant delivery pipe 103 and the pipeline between the exhaust pipe 3 and the four-way valve 105, and the medium-pressure suction pipe 116 can be selectively used The pipe 5 communicates with the refrigerant conveying pipe 103, and at this moment, one end of the pipe connecting the three-way valve 116 between the exhaust pipe 3 and the four-way valve 105 is closed. Furthermore, the gas refrigerant (pressure Pi) in the gas-liquid separator 108 flows into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com