Ceramic pressure sensor chip capable of accurately correcting and adjusting temperature drift error, correcting and adjusting system and correcting and adjusting method

A pressure sensor and trimming technology, which is used in the measurement of fluid pressure, the measurement of the property force of piezoelectric resistance materials, and instruments, etc., can solve problems such as different output voltages, and achieve the effects of scientific design, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

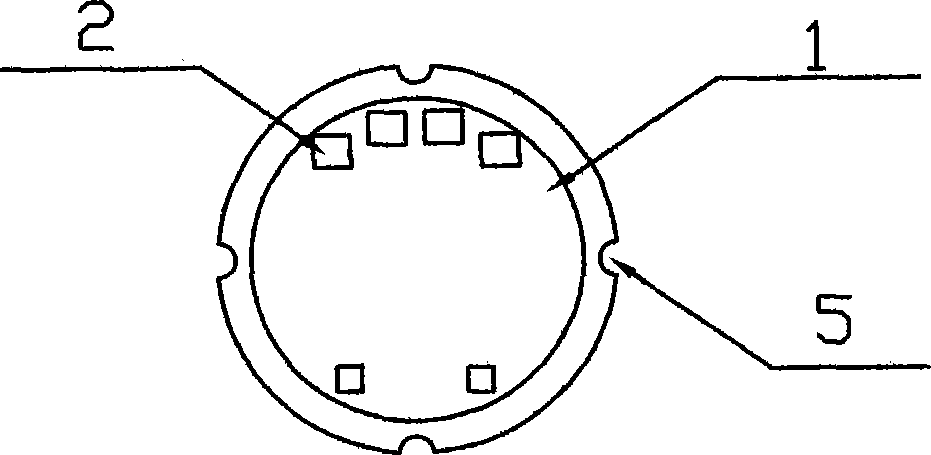

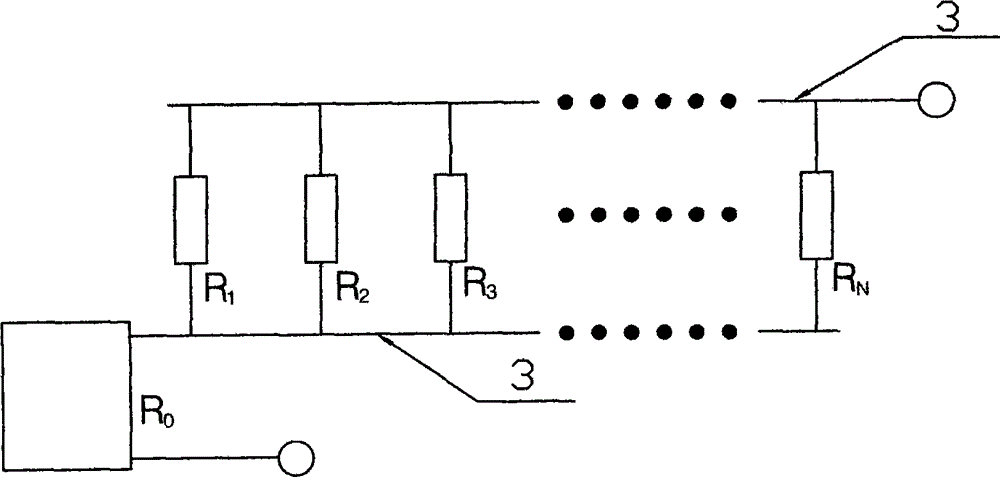

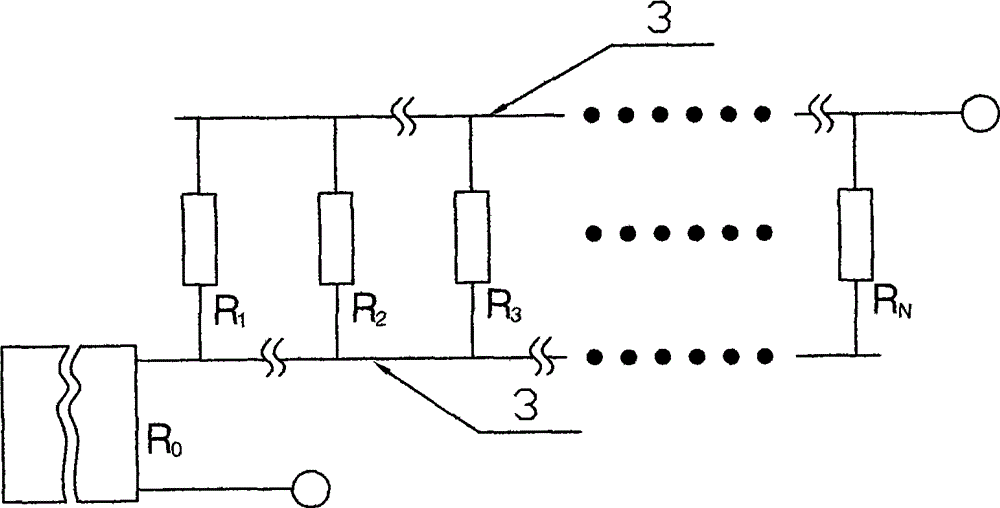

[0030] Implementation mode one: if Figure 1-5 As shown, the ceramic pressure sensor chip that can accurately adjust the temperature drift includes a chip body 1, and the chip body 1 is provided with four contacts 2, and is provided with a Wheatstone bridge circuit, which is characterized in that: Wheatstone A combined temperature drift compensation resistor is connected to the bridge arm of the bridge circuit, and the combined temperature drift compensation resistor includes an adjustable resistor R 0 and multiple coarse resistors R 1 , R 2 , R 2 ...R N , both ends of each coarse adjustment resistor R 1 , R 2 , R 2 ...R N respectively connected to two printed metal foil lines 3, the adjustable resistance R 0 It is connected in series to one of the metal foil lines 3.

[0031] like figure 1 As shown, the chip body 1 is provided with positioning notches 5 .

[0032] The temperature drift adjustment system of the ceramic pressure sensor chip that can accurately adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com