Method for improving troubleshooting efficiency of shear pin system of water turbine

A technology of system faults and shearing pins, which can be used in directions such as measuring the rate of increase and deceleration of fluids, detecting the appearance of fluids at leak points, and using liquid/vacuum degrees to measure liquid tightness, etc. Timely and accurate determination of fault points, long working hours and other issues, to achieve good economic benefits and promotion value, narrow the scope of investigation, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a method for improving the troubleshooting efficiency of the hydraulic turbine shear pin system, and the invention will be further described below in conjunction with the accompanying drawings and embodiments.

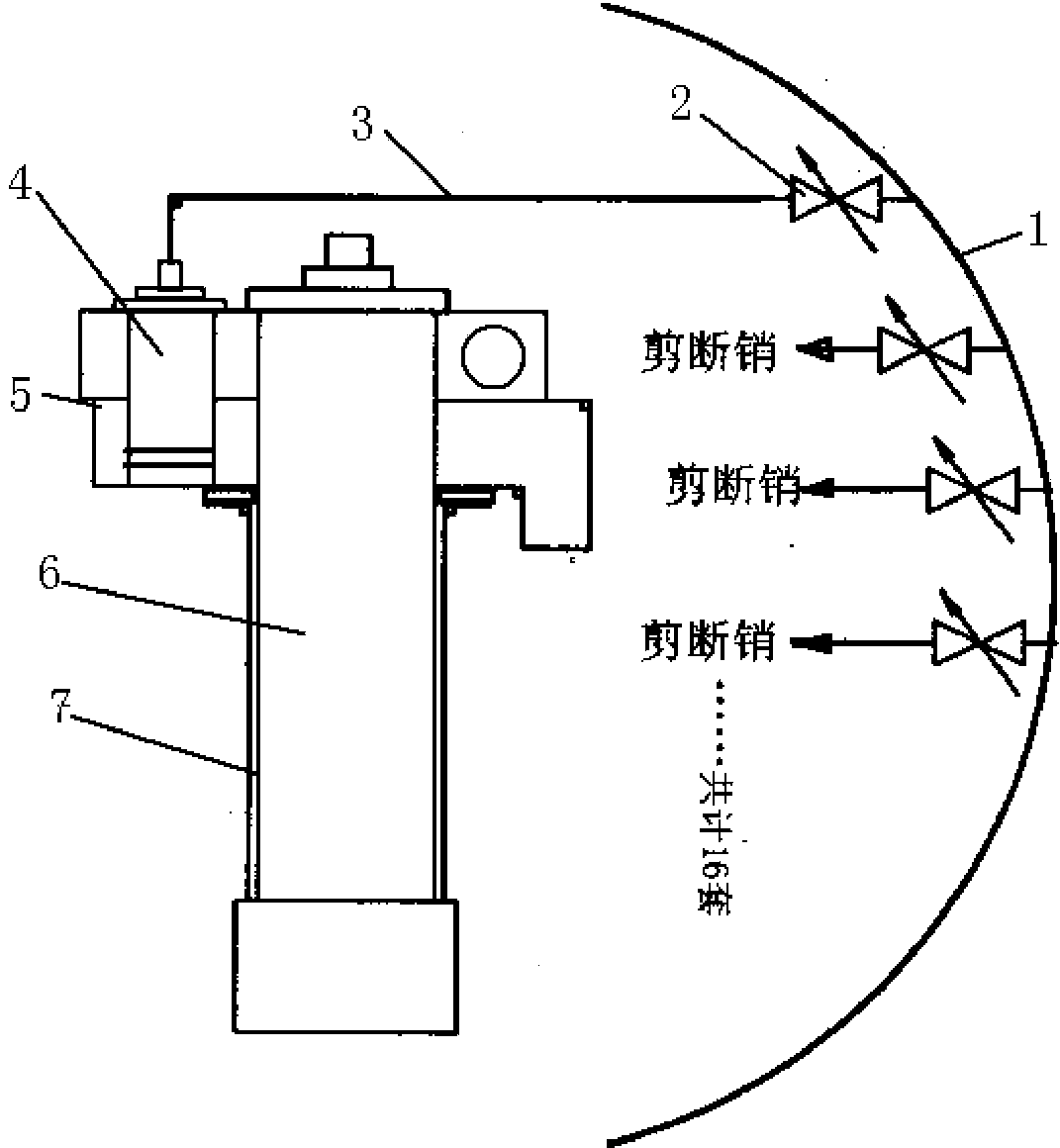

[0016] figure 1 Shown is a structural schematic diagram of the modified hydraulic turbine shear pin system. The shear pin system of the hydraulic turbine consists of 16 guide vanes per machine (composed of guide vane sleeves 7 sleeved on the outside of the guide vane shaft 6), and the shear pin 4 is fixed by the crank arm 5 on the upper part of the guide vanes. Pin 4; the manual control valve 2 is connected between the shear pin 4 and the stainless steel annular air supply pipe 1 by the air supply hose 3; together with the signal device, a signal monitoring system is formed. The shear pin is a safety device for the water guide mechanism of the turbine protective device.

[0017] The method for improving the troubleshooting efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com