Method for testing moisture distribution of asphalt mixture based on industrial computed tomography (CT)

A technology for asphalt mixture and distribution testing, which is applied in the direction of material analysis using radiation, etc., can solve the problem that the moisture distribution of asphalt mixture cannot be intuitively and accurately obtained, so as to avoid indistinguishability, improve analysis accuracy, and improve durability The effect of sex and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

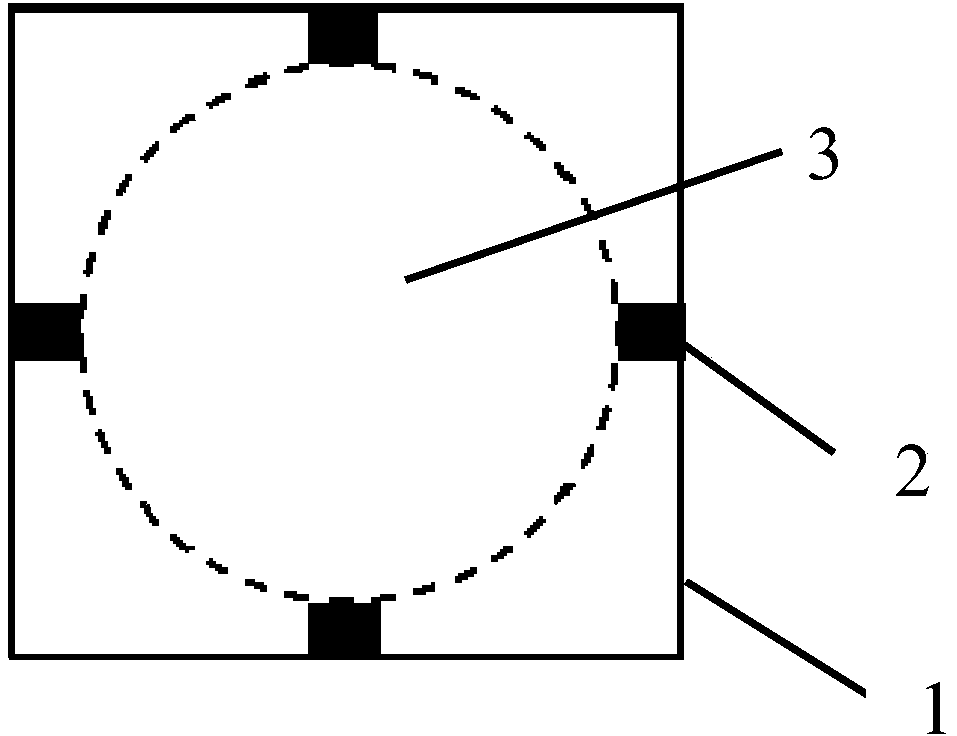

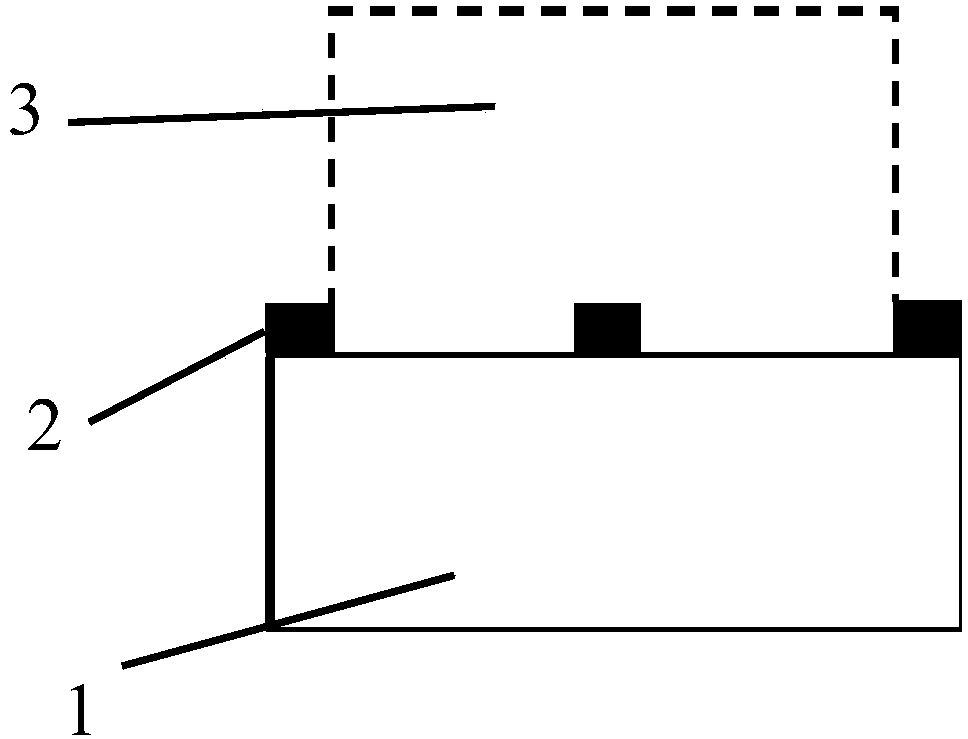

[0031] Specific implementation mode 1: This implementation mode is based on the industrial CT-based asphalt mixture water distribution test method according to the following steps:

[0032] 1. Fix the foam jig to the support table of the industrial CT machine, so that the vertical axis of the jig coincides with the rotation axis of the support table of the industrial CT machine;

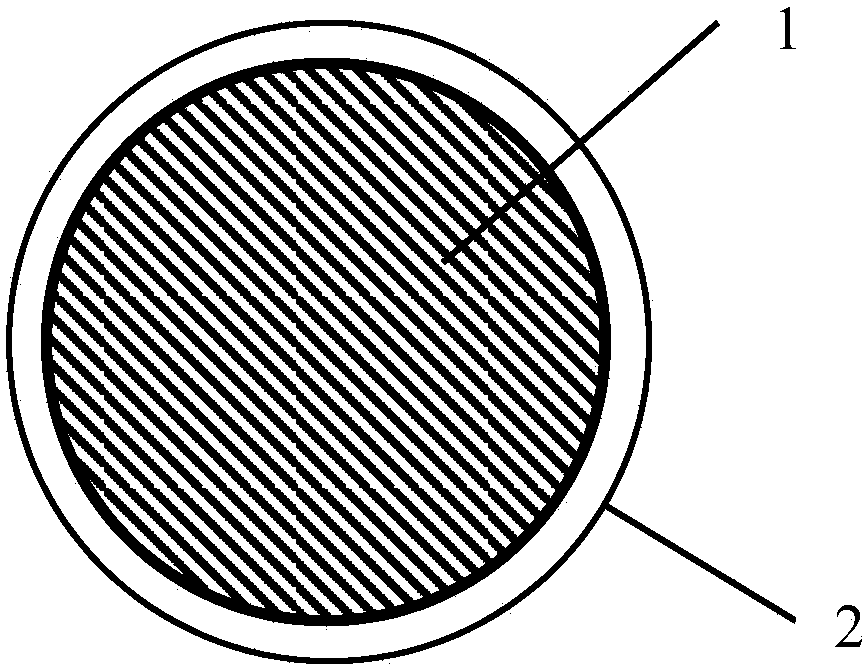

[0033] 2. Cover the X-ray exit position of the industrial CT machine with a metal sheet, start the industrial CT machine, warm up the industrial CT machine, and place the cylindrical dry asphalt mixture test piece in the fixture to ensure that the asphalt mixture When the test piece is within the receiving range of the detector, record the position coordinates of the asphalt mixture test piece;

[0034]3. Adjust the scanning parameters of the industrial CT machine. Set the scanning parameters to a voltage of 140-220kV, a current of 60-140μA, a number of rotating surfaces of 1500, an exposure time of ...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the gradation type of the asphalt mixture specimen is asphalt concrete AC, asphalt mastic macadam SMA, asphalt macadam AM or drainage asphalt wear layer OGFC. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that step 2 puts a metal sheet on the X-ray emission exit position of the industrial CT machine, and the metal sheet is a tin sheet or a copper sheet. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com