CMOS compatible silicon differential condenser microphone and method for manufacturing the same

A technology of capacitors and microphones, which is applied in the field of microphones and can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

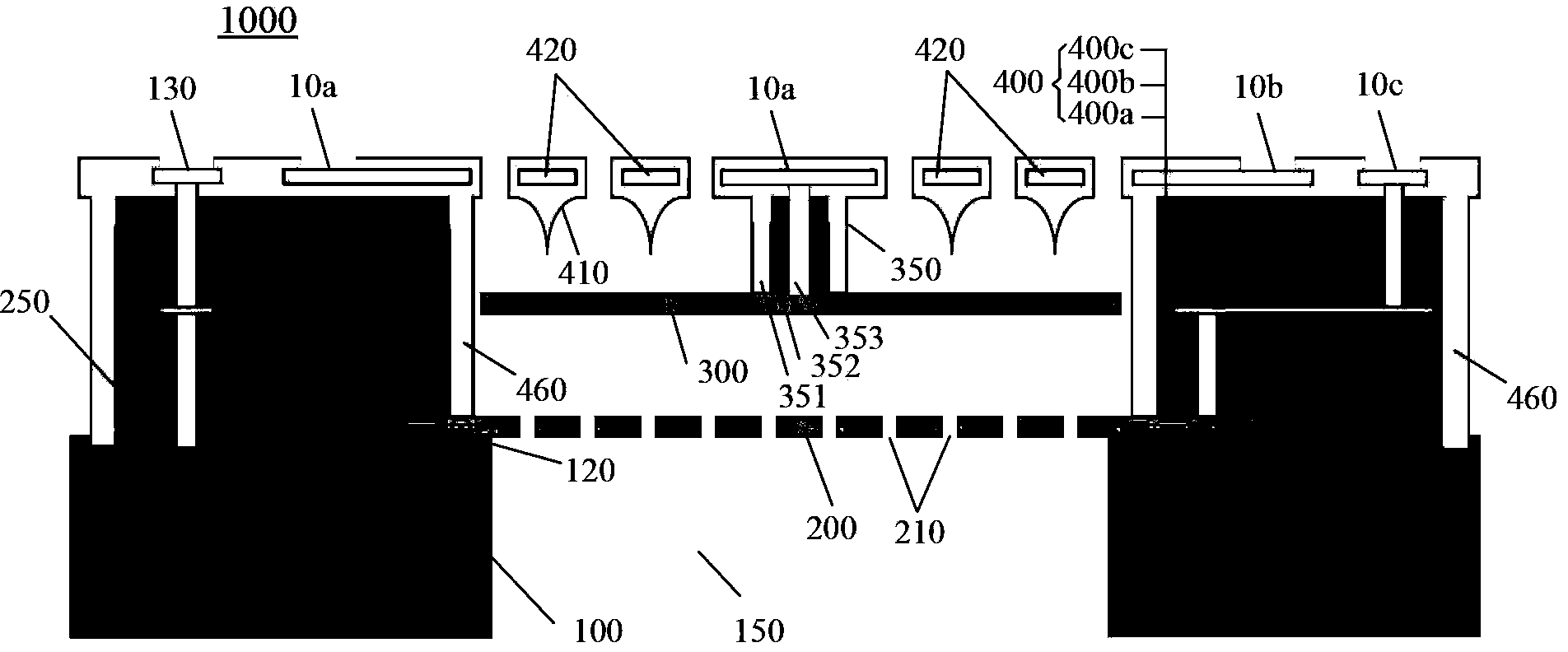

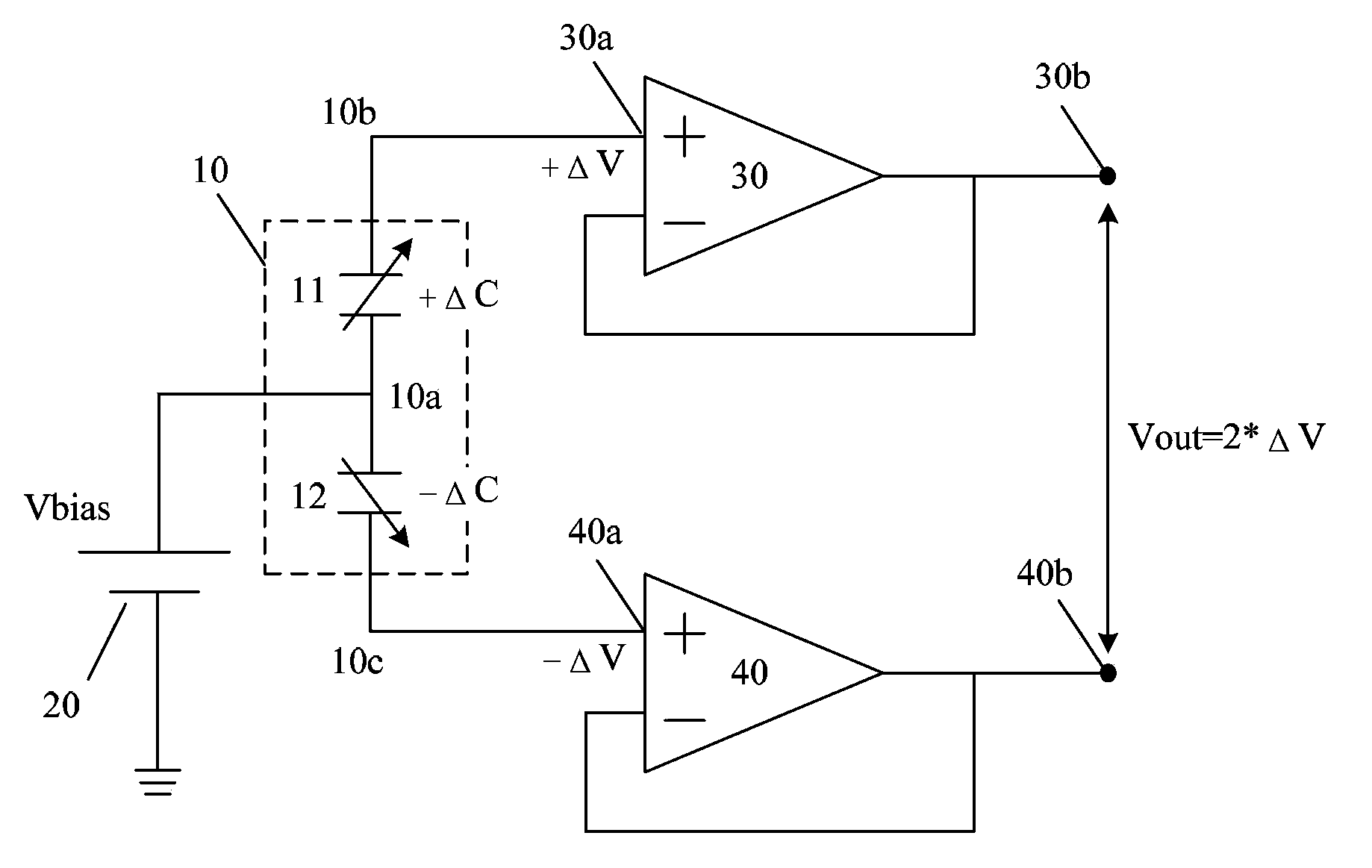

[0023] Below, refer to figure 1 The structure of the CMOS-compatible silicon differential capacitor microphone according to the first embodiment of the present invention will be described.

[0024] figure 1is a cross-sectional view showing the structure of the CMOS-compatible silicon differential capacitor microphone 1000 according to the first embodiment of the present invention. like figure 1 As shown, the CMOS-compatible silicon microphone 1000 according to the first embodiment of the present invention may include a silicon substrate 100 , a lower backplane 200 , an isolator 250 , a compliant diaphragm 300 , interconnection posts 350 and an upper backplane 400 . The diaphragm 300 and the lower back plate 200 form a lower variable capacitor, the diaphragm 300 and the upper back plate 400 form an upper variable capacitor, and the lower variable capacitor and the upper variable capacitor form a differential capacitor.

[0025] like figure 1 As shown, the silicon substrate ...

no. 2 example )

[0061] The following will refer to Figure 4 The structure of the CMOS-compatible silicon differential capacitor microphone 1000' according to the second embodiment of the present invention will be described. Will Figure 4 and figure 1 In contrast, the difference between the second embodiment of the present invention and the first embodiment is that, in the second embodiment, the periphery of the diaphragm 300 is suspended on the upper back plate 400, such as figure 1 In the first embodiment shown, the interconnection post 350 connects the center of the diaphragm 300 to the upper backplane 400 as shown in Figure 4 In the second embodiment shown, the interconnection pillar 350' is located at the periphery of the diaphragm 300, and a via metal 353' is formed in the spacer 250, and the via metal 353' connects the periphery of the conductive diaphragm 300 to the periphery of the diaphragm 300. The lead-out electrodes 10a formed in the upper back plate 400 are used to lead the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com