Semi-fermented acidic milk pudding and preparation method thereof

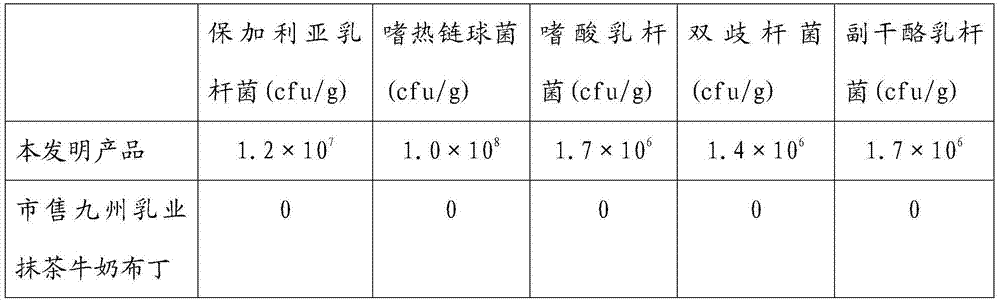

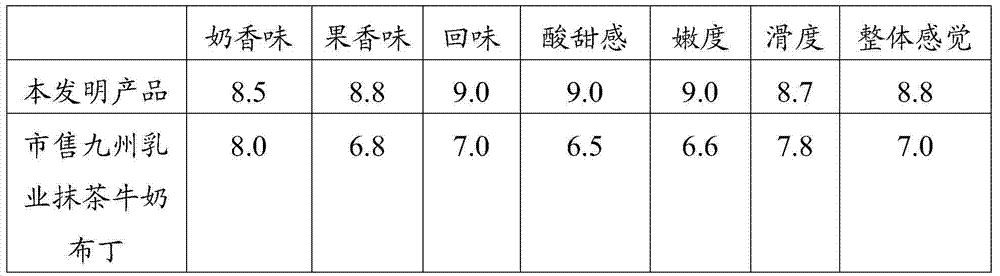

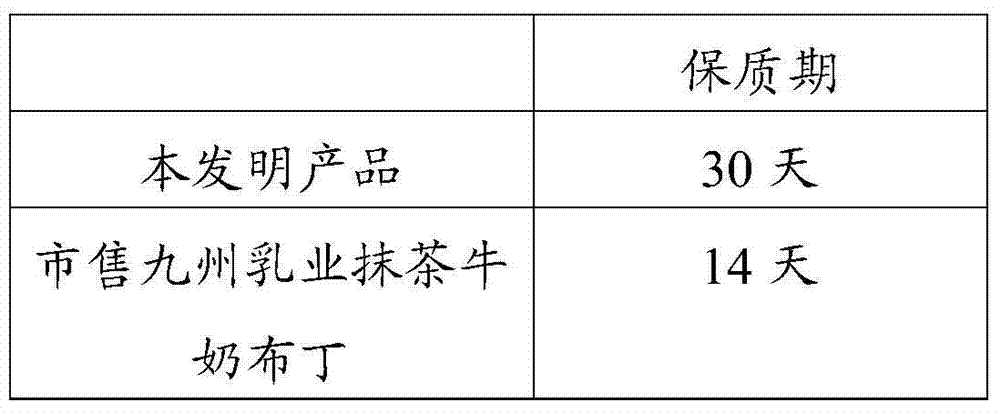

A milk pudding and semi-fermentation technology, applied in the food field, can solve problems such as being unsuitable for the growth of probiotics, without probiotics, etc., and achieve the effects of delicate and smooth sensory, unique flavor and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of semi-fermented sour milk pudding of the present invention and preparation method thereof are:

[0048] 1) Mixing: Mix 25kg of stabilizer and 50kg of white sugar, add 400kg of raw milk heated to 75°C, stir for 15 minutes, then add 24.9kg of mango puree and 0.1kg of essence, and stir for 10 minutes to obtain a mixture;

[0049] The stabilizer is a combination of 7kg of gelatin, 2kg of pectin, 15kg of modified starch, and 1kg of lactic acid fatty acid glycerides. The essence is a combination of 0.04kg of mango essence, 0.04kg of pineapple essence, and 0.02kg of yogurt essence.

[0050] 2) Homogenization: Homogenize the mixture obtained in step 1) at a temperature of 67°C and a pressure of 20Mpa;

[0051] 3) Sterilization: Sterilize the mixture obtained in step 2) at 95°C for 10 minutes;

[0052] 4) Mixing: Mix the mixture obtained in step 3) with 500kg of fermented milk;

[0053] 5) Stirring: Stir the mixture obtained in step 4) for 20 minutes, and control the ...

Embodiment 2

[0067] A kind of semi-fermented sour milk pudding of the present invention and preparation method thereof are:

[0068] 1) Mixing: Mix 29.7kg of stabilizer and 30kg of white sugar, add 420kg of raw milk heated to 77°C, stir for 17 minutes, then add 10kg of mango puree and 0.3kg of essence, and stir for 7 minutes to obtain a mixture;

[0069] The stabilizer is a combination of 8 kg of gelatin, 2 kg of pectin, 18.2 kg of modified starch, and 1.5 kg of lactic acid fatty acid glycerides. The flavor is a combination of 0.12 kg of mango flavor, 0.12 kg of pineapple flavor, and 0.06 kg of yogurt flavor.

[0070] 2) Homogenization: Homogenize the mixture obtained in step 1) at a temperature of 65°C and a pressure of 20Mpa;

[0071] 3) Sterilization: Sterilize the mixture obtained in step 2) at 95°C for 10 minutes;

[0072] 4) Mixing: Mix the mixture obtained in step 3) with 510kg of fermented milk;

[0073] 5) Stirring: Stir the mixture obtained in step 4) for 25 minutes, and contro...

Embodiment 3

[0087] A kind of semi-fermented sour milk pudding of the present invention and preparation method thereof are:

[0088] 1) Mixing: Mix 10kg of stabilizer and 40kg of white sugar, add 440kg of raw milk heated to 75°C, stir for 17 minutes, then add 19.8kg of mango puree and 0.2kg of essence, and stir for 12 minutes to obtain a mixture;

[0089] The stabilizer is a combination of 5kg of gelatin, 1.5kg of pectin, 3kg of modified starch, and 0.5kg of lactic acid fatty acid glycerides. The essence is a combination of 0.08kg of mango essence, 0.08kg of pineapple essence, and 0.04kg of yogurt essence.

[0090] 2) Homogenization: Homogenize the mixture obtained in step 1) at a temperature of 68°C and a pressure of 19Mpa;

[0091] 3) Sterilization: Sterilize the mixture obtained in step 2) at 95°C for 10 minutes;

[0092] 4) Mixing: mix the mixture obtained in step 3) with 490kg of fermented milk;

[0093] 5) Stirring: Stir the mixture obtained in step 4) for 23 minutes, and control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com