Flame tube repair method

A repair method and flame tube technology, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve problems such as waste of human, material and financial resources, and achieve the effect of saving costs, saving the cost of repeated adjustments, and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

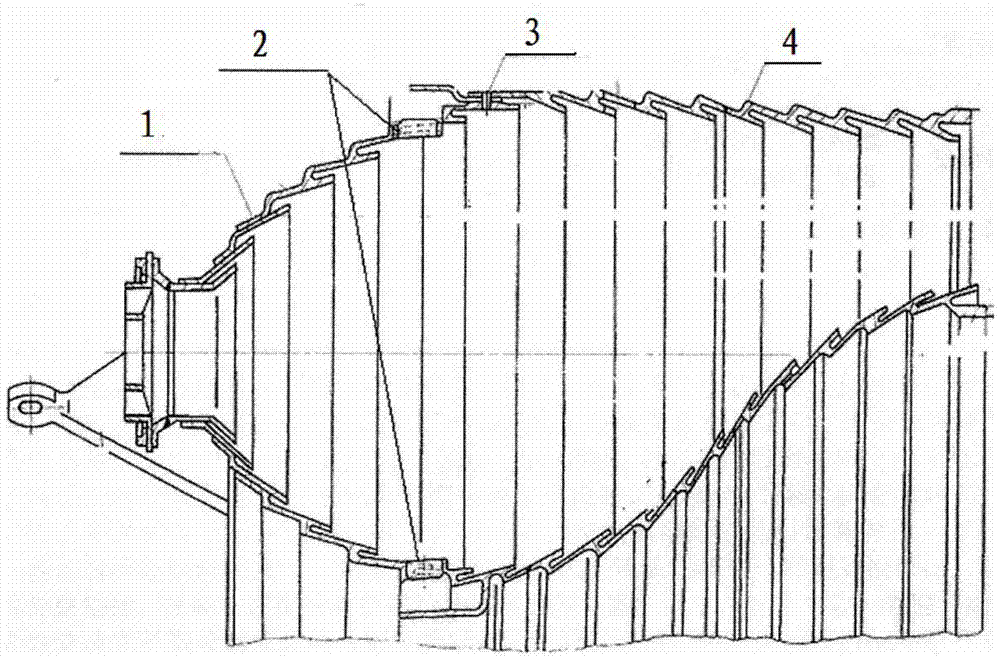

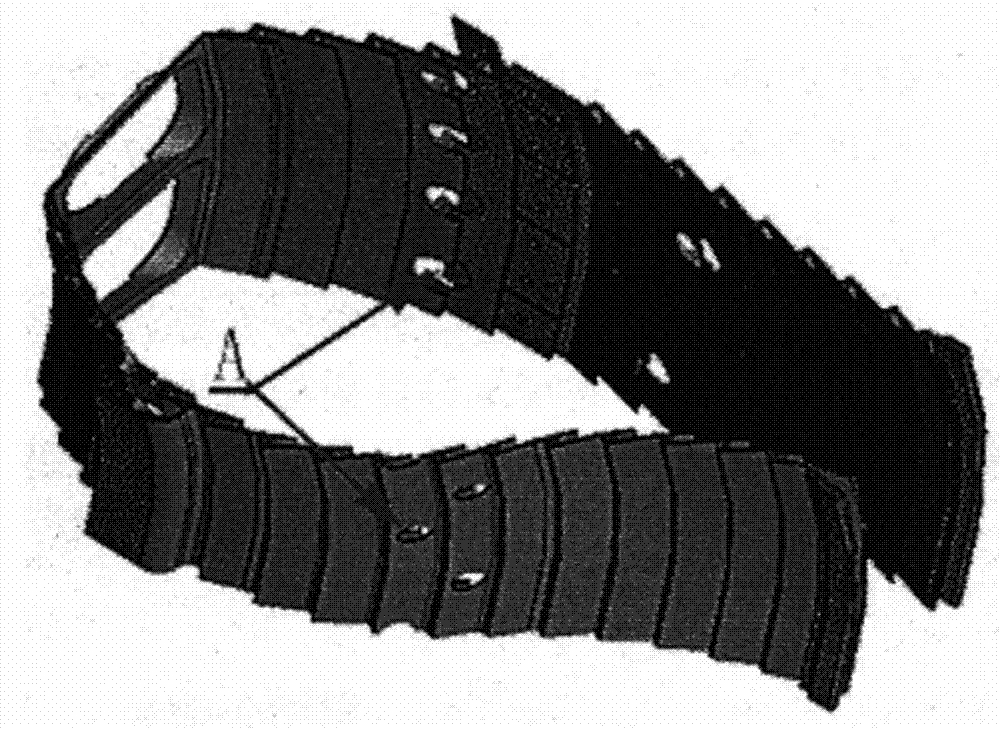

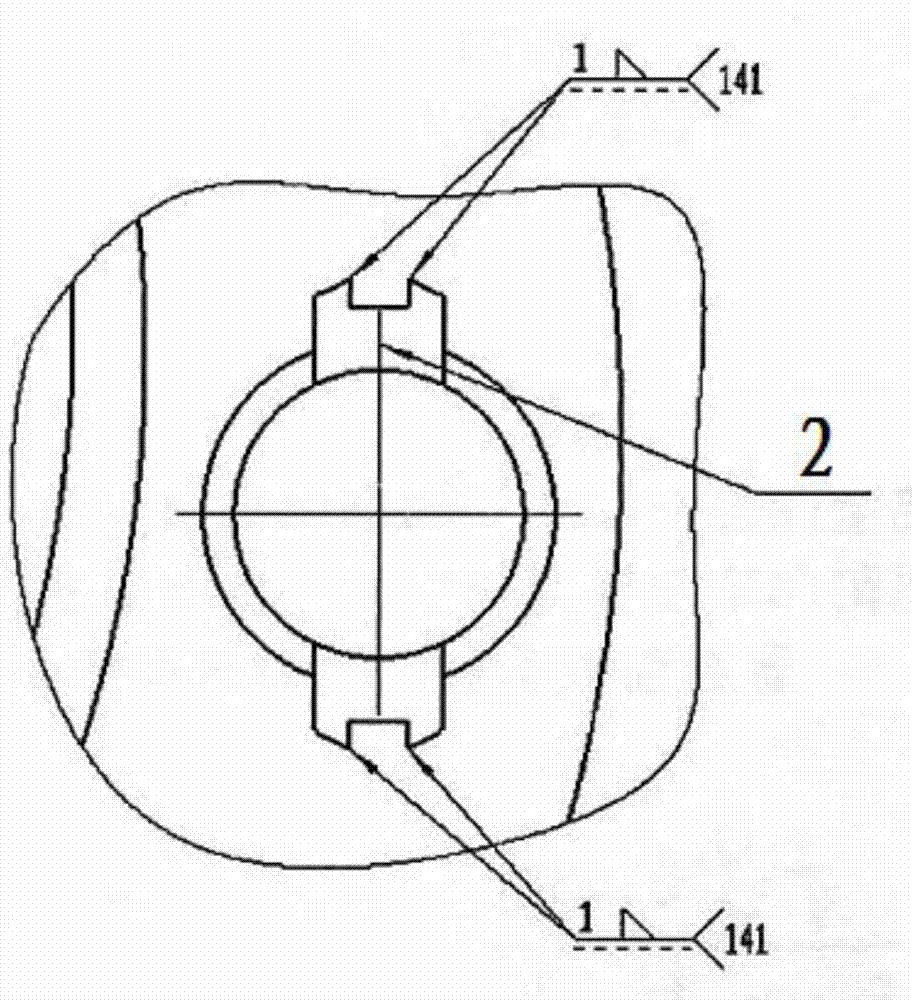

[0034] Such as Figure 1-Figure 3 As shown, the flame cylinder is one of the important hot end parts in the engine combustion chamber unit. The material of the flame cylinder is nickel-based deformed superalloy GH648, which is formed by vacuum induction melting. The inner surface is coated with heat-resistant coating B KⅡH-5, and the main composition of the coating is Ni, A1. When the combustion chamber is started and ignited, the predetermined combustion temperature (2000K ~ 2400K) is quickly reached in the flame tube. The flame tube is composed of a head (the head and the inner mixer are collectively referred to as the head), an outer mixer, and the outer mixer and the head are connected by 112 rivets. The head and the outer mixer segment are connected by 4 argon arc welding seams and 2 spot roll welding seams. There are 42 combustion-supporting hole drainage sleeves welded on the inner wall of the head, and 56 combustion-supporting hole drainage sleeves are welded on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com