Welding material and welding method for titanium-steel composite board

A composite plate and welding wire technology, applied in the direction of welding/cutting medium/material, welding/welding/cutting articles, welding medium, etc., can solve the problems of cracking of intermetallic compounds, difficulty in obtaining high-performance parts, etc., and achieve pre-welding treatment The effect of simplification, high tensile strength, and easy engineering promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

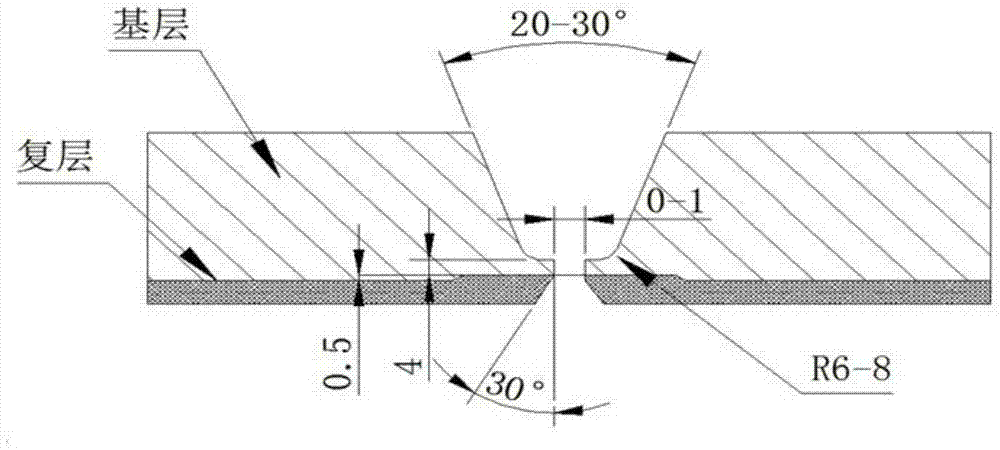

Method used

Image

Examples

Embodiment 1

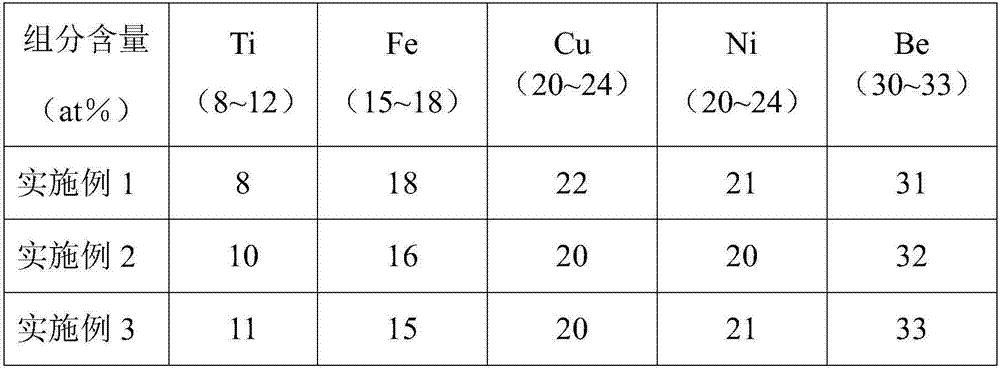

[0037] TIG welding was performed on TA2 / 0Cr18Ni9Ti with the high-entropy alloy welding wire obtained according to the component contents in the above-mentioned Table 1, and the final high-entropy alloy weld composition of Example 1 in the above-mentioned Table 2 was obtained, and there was no crack in the transition zone of the weld. The tensile strength of TA2 / 0Cr18Ni9TiTIG welded joint is about 450Mpa.

Embodiment 2

[0039] TIG welding was performed on TA2 / 0Cr18Ni9Ti with the high-entropy alloy welding wire obtained according to the component content in the above-mentioned Table 1, and the final high-entropy alloy weld composition of Example 2 in the above-mentioned Table 2 was obtained, and there was no crack in the transition zone of the weld. The tensile strength of TA2 / 0Cr18Ni9TiTIG welded joint is about 462Mpa.

Embodiment 3

[0041] TIG welding was performed on TA2 / 0Cr18Ni9Ti with the high-entropy alloy welding wire obtained according to the component contents in the above-mentioned Table 1, and the final high-entropy alloy weld composition of Example 3 in the above-mentioned Table 2 was obtained, and there was no crack in the transition zone of the weld. The tensile strength of TA2 / 0Cr18Ni9TiTIG welded joint is about 471Mpa.

[0042] It can be seen that the high-entropy alloy welding wire of the present invention has excellent strength, toughness and corrosion resistance, is not easy to form a brittle intermetallic compound phase, and is easy to obtain a high-performance titanium-steel composite plate welded structural steel base, and the welding wire is easy to process and shape The welding operation process of the high-entropy alloy welding wire is simple, convenient and efficient, and easy to popularize.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com