Engine suspension assembly adopting bracket for limiting

An engine mount and assembly technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as inability to apply to commercial vehicles and poor mechanical strength, and achieve strong stress resistance, long service life, and mechanical The effect of excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

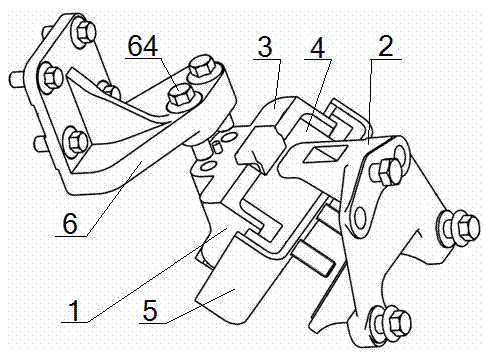

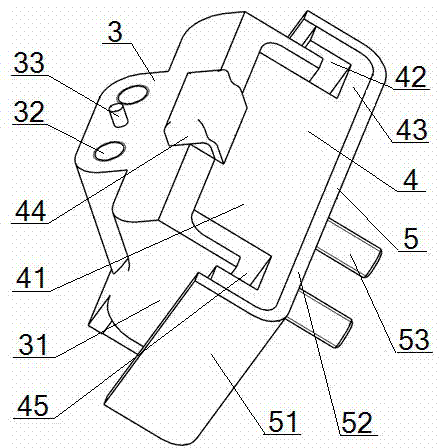

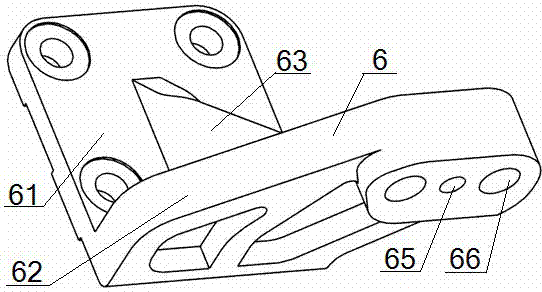

[0044] see figure 1 – Figure 4 , a bracket-limited engine suspension assembly, comprising a suspension cushion assembly 1 and a suspension bracket 2 connected to each other, the suspension cushion assembly 1 comprising an upper skeleton 3, a vulcanized rubber 4 and a lower skeleton 5, the upper skeleton 3 is vulcanized with the lower skeleton 5 through vulcanized rubber 4, and the suspension bracket 2 includes a bottom bracket 21, a limit frame 22 and a mounting seat 23, and the limit frame 22 passes through the mounting seat 23 is fixedly connected with the bottom bracket 21, and the bottom bracket 21 is connected with the bottom of the upper frame 3 through the lower frame 5 and the vulcanized rubber 4 in turn, and the top of the upper frame 3 is limitedly matched with the limit frame 22, and the bottom bracket Frame 21 comprises supporting plate 24 and side plate 25, and the top of supporting plate 24 is fixedly connected with the middle part of mounting base 23, and both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com