Radiation-proof composite insulation board doped with carbon nano tubes

A technology of carbon nanotubes and composite heat preservation, applied in heat preservation, building components, buildings, etc., can solve problems such as lack of radiation protection and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

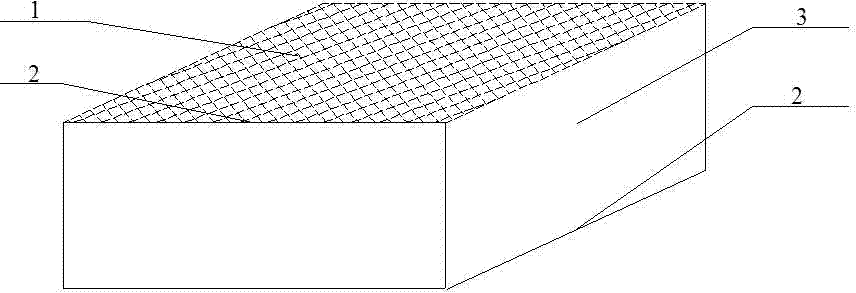

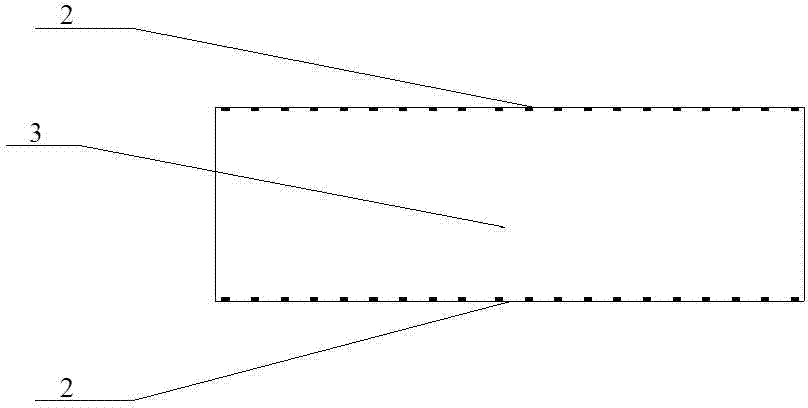

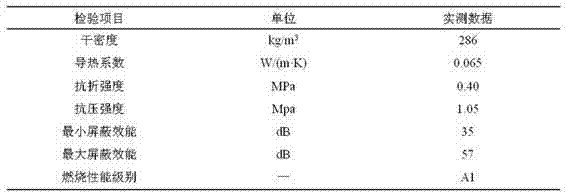

[0017] like figure 1 Shown is a schematic structural view of the radiation-proof composite thermal insulation board doped with carbon nanotubes of the present invention. Using expanded perlite, water glass, cement, carbon nanotubes, and aluminum alloy grids as raw materials, the carbon nanotubes are first dispersed into the water glass solution, and then the expanded perlite is placed in a mixer for stirring, and the water glass is mixed with a spray gun. / Carbon nanotube mixed solution and dry cement powder are sprayed on the surface of the expanded perlite which is being stirred respectively to obtain the expanded perlite semi-dry material; then a layer of aluminum alloy grid is laid on the bottom of the mold, and the expanded perlite semi-dry material is placed in the mold After the dry material is pre-pressed and shaped, a layer of aluminum alloy grid is laid on the pre-pressed and shaped expanded perlite semi-dry material for pressure molding, and after demoulding and cur...

Embodiment 2

[0026] like figure 1 Shown is a schematic structural view of the radiation-proof composite thermal insulation board doped with carbon nanotubes of the present invention. Using expanded perlite, water glass, cement, carbon nanotubes, and aluminum alloy grids as raw materials, the carbon nanotubes are first dispersed into the water glass solution, and then the expanded perlite is placed in a mixer for stirring, and the water glass is mixed with a spray gun. / Carbon nanotube mixed solution and dry cement powder are sprayed on the surface of the expanded perlite which is being stirred respectively to obtain the expanded perlite semi-dry material; then a layer of aluminum alloy grid is laid on the bottom of the mold, and the expanded perlite semi-dry material is placed in the mold After the dry material is pre-pressed and shaped, a layer of aluminum alloy grid is laid on the pre-pressed and shaped expanded perlite semi-dry material for pressure molding, and after demoulding and cur...

Embodiment 3

[0035] like figure 1 Shown is a schematic structural view of the radiation-proof composite thermal insulation board doped with carbon nanotubes of the present invention. Using expanded perlite, water glass, cement, carbon nanotubes, and aluminum alloy grids as raw materials, the carbon nanotubes are first dispersed into the water glass solution, and then the expanded perlite is placed in a mixer for stirring, and the water glass is mixed with a spray gun. / Carbon nanotube mixed solution and dry cement powder are sprayed on the surface of the expanded perlite which is being stirred respectively to obtain the expanded perlite semi-dry material; then a layer of aluminum alloy grid is laid on the bottom of the mold, and the expanded perlite semi-dry material is placed in the mold After the dry material is pre-pressed and shaped, a layer of aluminum alloy grid is laid on the pre-pressed and shaped expanded perlite semi-dry material for pressure molding, and after demoulding and cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com