Improved animal fat processing technology

A technology of animal fat and animal fat, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of high cost and complicated treatment process, and achieve the effect of low cost, simple process route and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

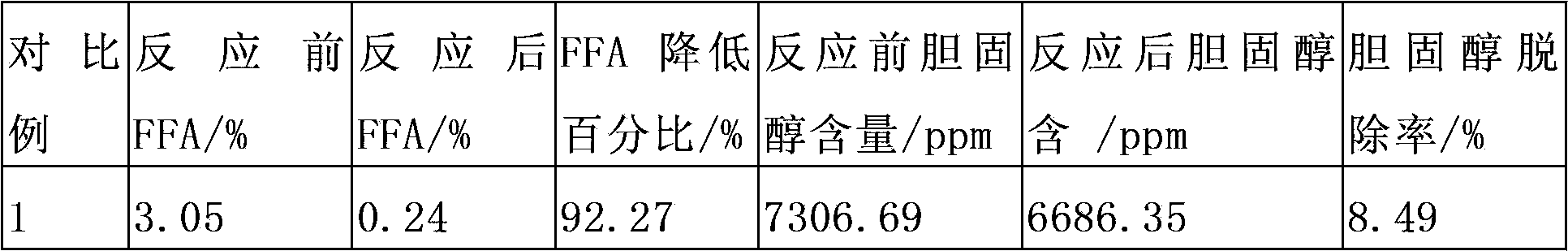

[0128] The impact of embodiment 1 excess alkali dosage on cholesterol and free fatty acid removal rate

[0129] Get 30g of hairy fish oil and heat it to 30°C. Make NaOH into an alkaline aqueous solution with a concentration of 20%, and the excess alkali dosage is 50-1000% of the theoretical alkali dosage, and then slowly add it into the heated hairy fish oil to make it react with the oil, and stir it under the condition of 60r / m for 30 minute. Then centrifuge at 5000rpm for 5 minutes to separate the precipitate, take the light phase, and obtain fish oil with low cholesterol and low free fatty acids (results are shown in Table 2); The ratio of oil and fat, the results show that the amount of fatty acid salt generated is 5% (50% of excess alkali consumption), 10% (200% of excess alkali consumption) and 20% (500% of excess alkali consumption) of the oil weight and 36% (1000% of excess alkali consumption).

[0130] Table 2

[0131]

[0132] According to table 2 result, exce...

Embodiment 2

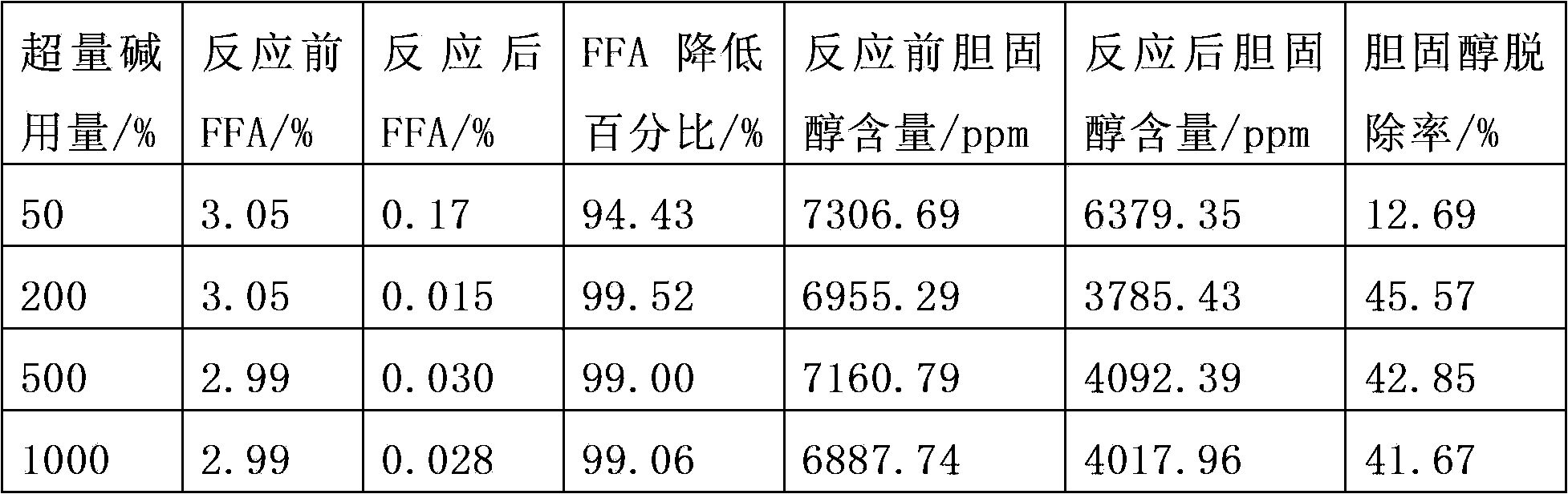

[0133] The influence of embodiment 2 lye concentration on cholesterol and free fatty acid removal rate

[0134] Get 30g of hairy fish oil and heat it to 30°C. Make NaOH into an alkaline aqueous solution with a concentration of 5-40%, and the excess alkali dosage is 200% of the theoretical alkali dosage, then slowly add it to make it react with the oil, stir at 60r / m for 30 minutes, and then rotate at 5000rpm Centrifuge for 5 minutes to separate the precipitate, and take the light phase to obtain fish oil with low cholesterol and low free fatty acid. The test results are listed in Table 3 below.

[0135] table 3

[0136]

[0137] According to the results in Table 3, under a certain excess alkali, the higher the concentration of lye, the higher the removal rate of FFA and cholesterol. However, if the concentration of lye is too high, the surface area of soapstock formed is too small, which affects the adsorption of cholesterol and the like.

Embodiment 3

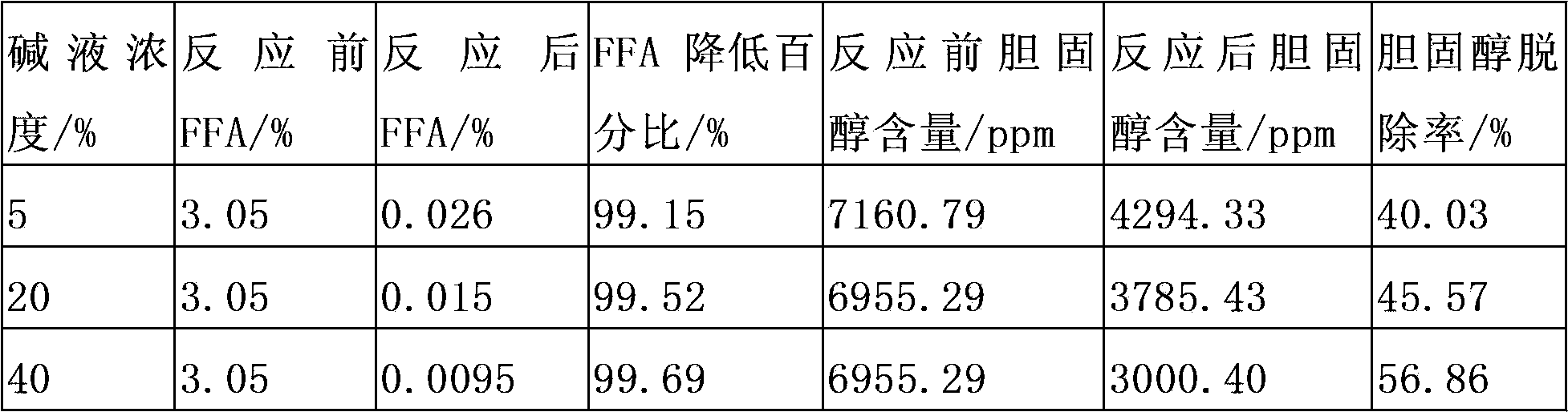

[0138] The type of embodiment 3 alkali is on the influence of cholesterol and free fatty acid removal rate

[0139] Take 30g of mackerel oil, heat it to 30°C, make an alkali or alkali composition into a 20% alkaline aqueous solution, the excess alkali dosage is 200% of the theoretical alkali dosage, and then add it slowly to make it react with the oil , stirred under 60r / m for 30 minutes, then centrifuged at 5000rpm for 5 minutes to separate the precipitate, and took the light phase to obtain fish oil with low cholesterol and low free fatty acids. The test results are listed in Table 4 below.

[0140] Table 4

[0141]

[0142] According to the results in Table 4, different alkalis show different process effects due to different alkalinity and other reasons. Sodium hydroxide and potassium hydroxide have strong alkalinity and good deacidification and cholesterol removal effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com