Liquid microbial leaf fertilizer, and production method and applications thereof

A foliar fertilizer and microbial technology, applied in the field of liquid microbial fertilizer and its production, can solve the problems of single ingredient and restricted scope of application, and achieve the effects of protecting the environment, saving resources, and improving the utilization rate of fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

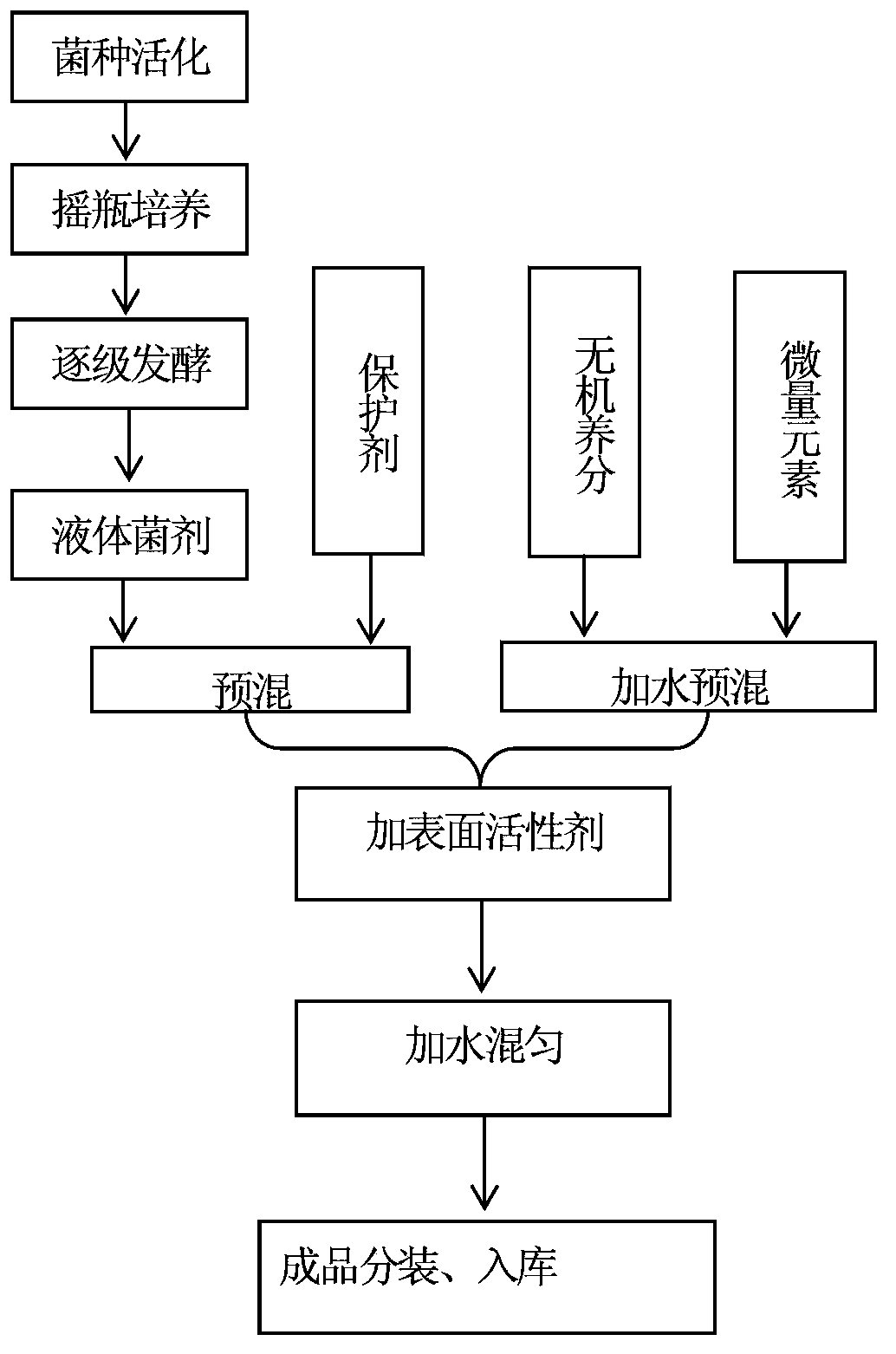

Method used

Image

Examples

Embodiment 1

[0032] 1. Microbial bacteria liquid: the formula of the strain fermentation medium is 50% of yeast waste liquid, 1.4% of silkworm chrysalis powder, 0.7% of peptone, 0.35% of gelatinized corn flour, 0.21% of NaCl, KH 2 PO 4 0.14%, MgSO 4 0.07%, pH 7. The effective number of viable bacteria in the microbial liquid is 4.7×10 8 per milliliter, the content of zeatin is about 0.69mg / mL.

[0033]2. Raw material formula: add according to the following formula. The trace element is borax and chelated zinc, the ratio is 2:3; the protective agent is sodium benzoate and molasses, the ratio is 1:1.

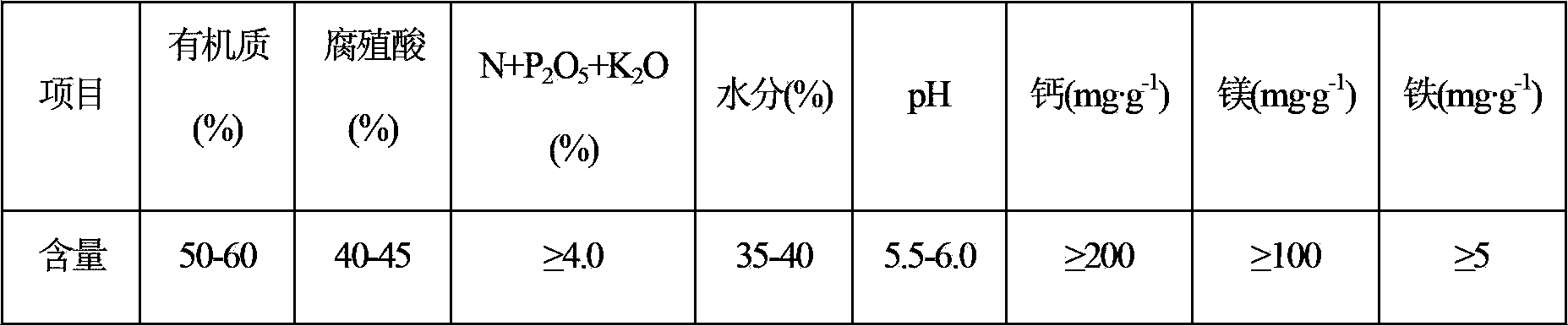

[0034] Table 3 Addition formula of microbial foliar fertilizer raw materials

[0035]

[0036] 3. Mix the inorganic nutrients with 40% (total mass) water; add the protective agent into the bacterial liquid, stir evenly and then add the inorganic nutrients; finally add the fully dissolved surfactant and the rest of the water to make microbial leaves surface fertilizer. The technical...

Embodiment 2

[0041] 1. Microbial bacteria liquid: the formula of the strain fermentation medium is 60% of yeast waste liquid, 1.2% of silkworm chrysalis powder, 0.6% of peptone, 0.3% of gelatinized corn flour, 0.18% of NaCl, KH 2 PO 4 0.12%, MgSO 4 0.06%, pH 7. The effective number of viable bacteria in the microbial liquid is 4.2×10 8 per milliliter, the content of zeatin is about 0.73mg / mL.

[0042] 2. Raw material formula: see Table 5. Trace element, protective agent are the same as example one.

[0043] Table 5 Addition formula of microbial foliar fertilizer raw materials

[0044]

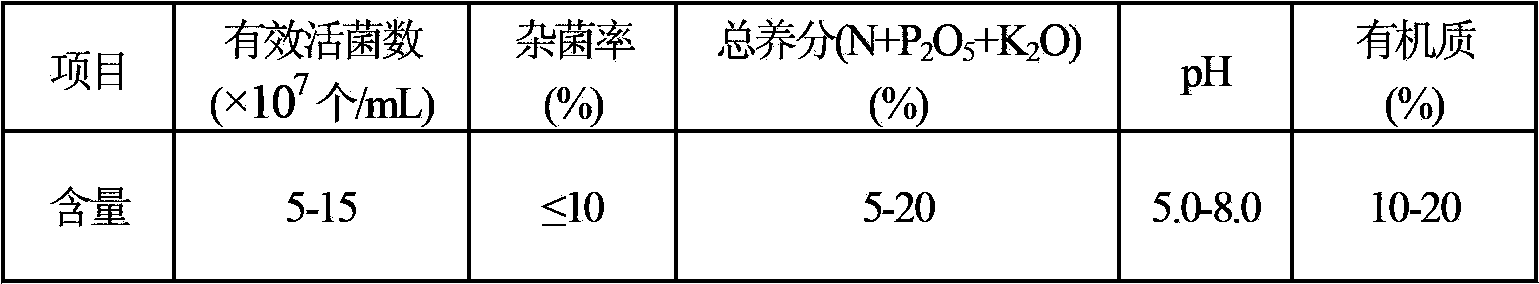

[0045] 3. Mixing and compounding: the same as Example 1. See Table 6 for technical indicators of microbial foliar fertilizers.

[0046] Table 6 Technical indicators of microbial foliar fertilizers

[0047]

[0048] 4. Sub-loading into warehouses: the same as Example 1.

Embodiment 3

[0050] 1. Microbial bacteria liquid: the formula of the strain fermentation medium is 55% of yeast waste liquid, 1.5% of silkworm chrysalis powder, 0.75% of peptone, 0.4% of gelatinized corn flour, 0.2% of NaCl, KH 2 PO 4 0.15%, MgSO 4 0.08%, pH 7. The effective number of viable bacteria in the microbial liquid is 3.6×10 8 per milliliter, the content of zeatin is about 0.71mg / mL.

[0051] 2. Raw material formula: see Table 7. Trace elements are the same as Example 1, and the protective agent is glycerin and molasses in a ratio of 1:1.

[0052] Table 7 Addition formula of microbial foliar fertilizer raw materials

[0053]

[0054] 3. Mixing and compounding: except that inorganic nutrients are premixed with 30% water, the rest are the same as Example 1. See Table 8 for technical indicators of microbial foliar fertilizers.

[0055] Table 8 Technical indicators of microbial foliar fertilizers

[0056]

[0057] 4. Sub-loading into warehouses: the same as Example 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com