Steel for petroleum sleeve connecting piece and production method of steel

A technology of petroleum casing and manufacturing method, applied in the field of metallurgy, can solve the problems of dense organization, poor composition uniformity, increased cost of raw materials, and high rejection rate, so as to ensure surface quality, reduce structural stress and thermal stress, and avoid internal cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

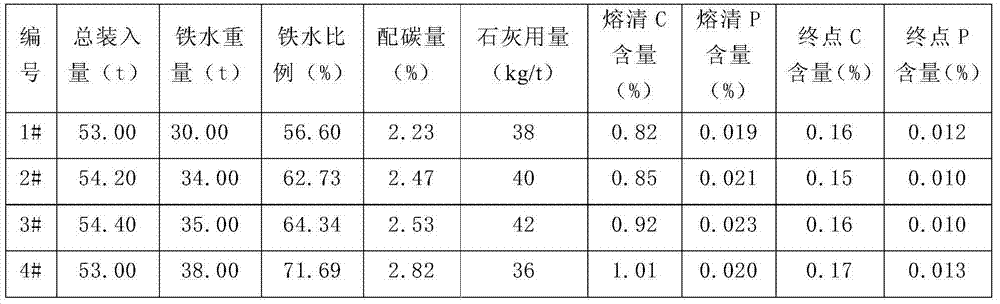

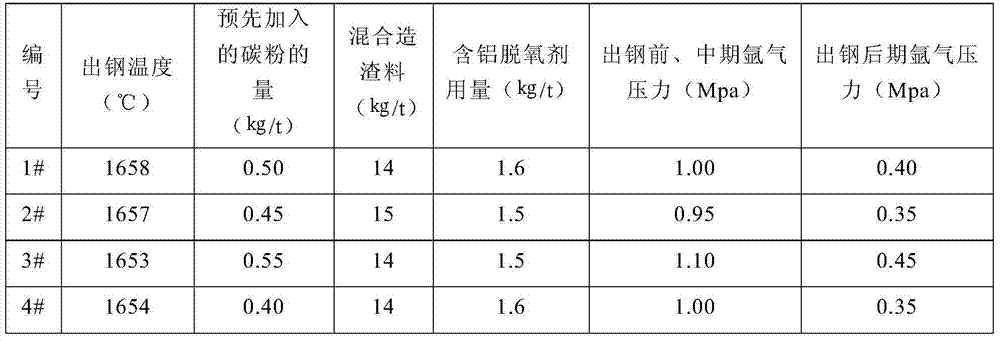

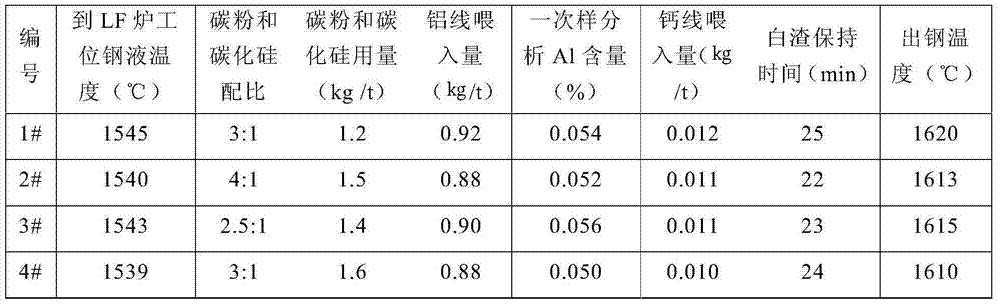

[0041] The preparation method of the continuous casting round billet for petroleum casing connectors provided by the present invention includes the following production steps: electric furnace primary refining process→LF refining process→VD vacuum degassing process→continuous casting process→slab slow cooling process→inspection , Finishing process;

[0042] The following percentages are mass percentages unless otherwise specified.

[0043] The initial smelting process of electric furnace: adopt the furnace material structure of scrap steel and molten iron, in which the mass percentage of molten iron accounts for 50% to 75%; Auxiliary; combined with oxygen blowing, blowing carbon powder or other carbon powder-containing agents to create foam slag; adding slagging materials such as lime to make slag dephosphorization; eccentric furnace bottom tapping, leaving steel and slag operation; during the tapping process , stirring with argon blowing at the bottom;

[0044] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com