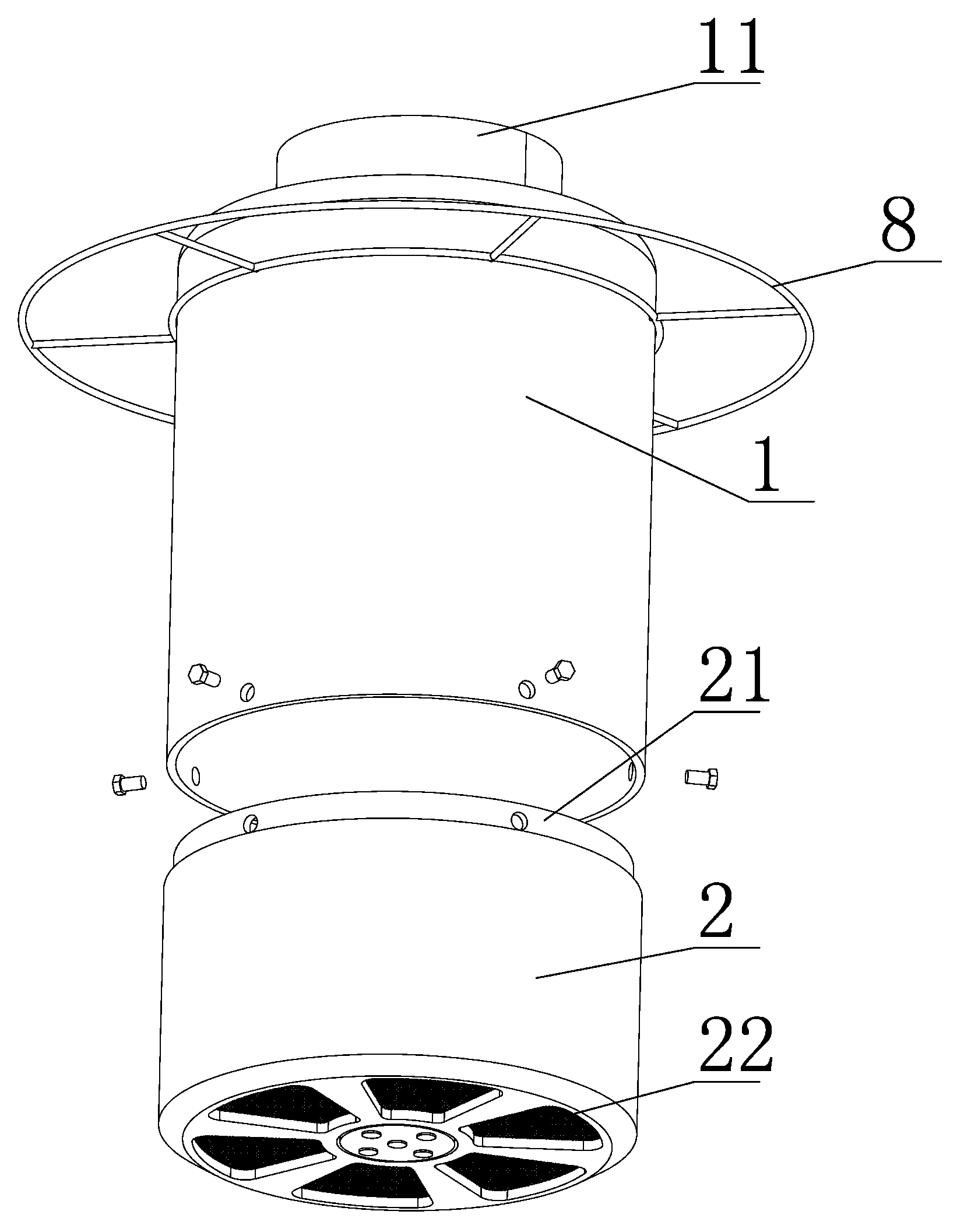

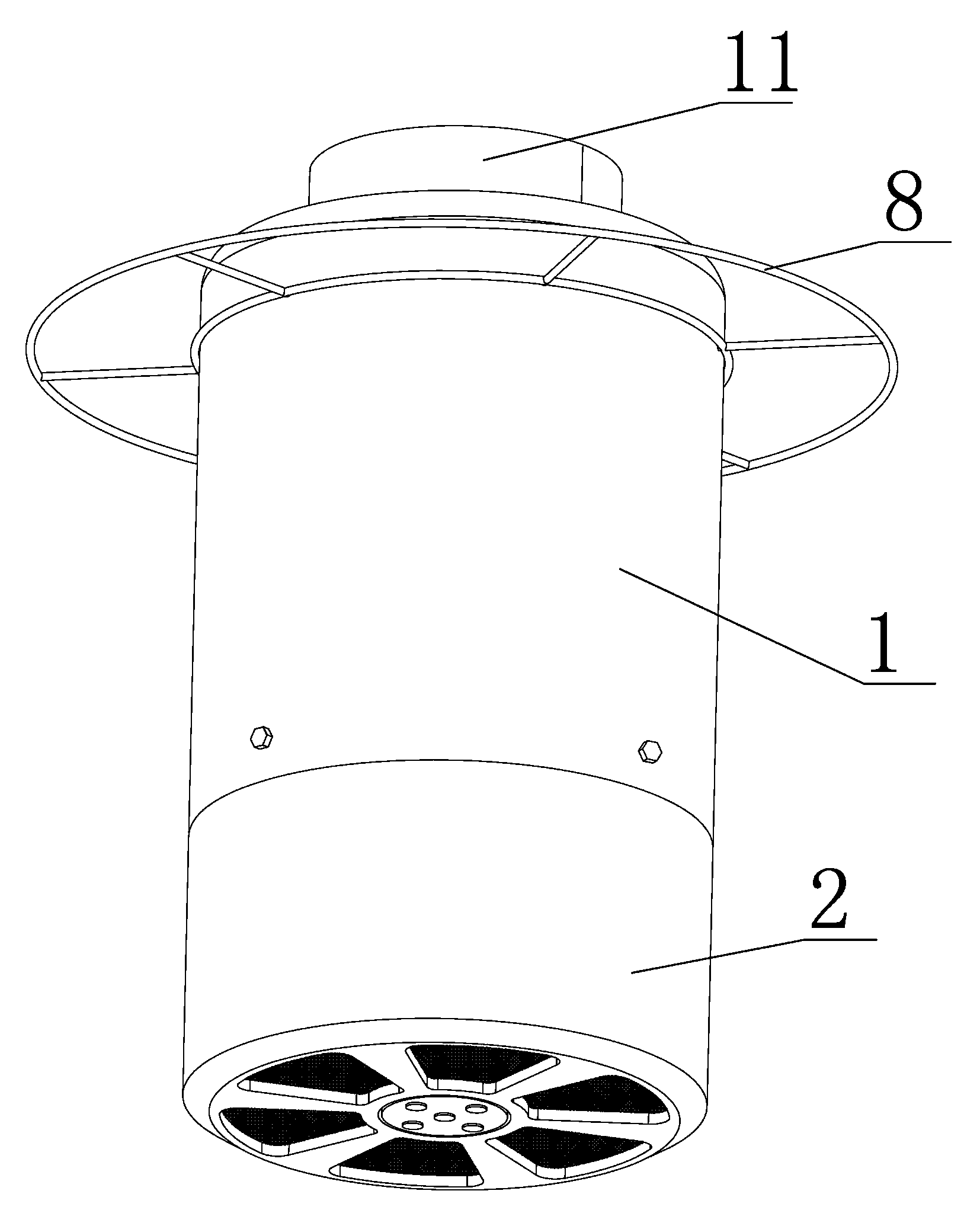

Range hood ventilation module and its assembling method

An assembly method and a technology for a range hood, which are applied in the directions of removing oil fume, heating methods, and household heating, can solve the problems of smoking power loss, increase aerodynamic noise, and large flow loss at the fan outlet, and reduce working noise and energy consumption. , The effect of reducing working noise and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

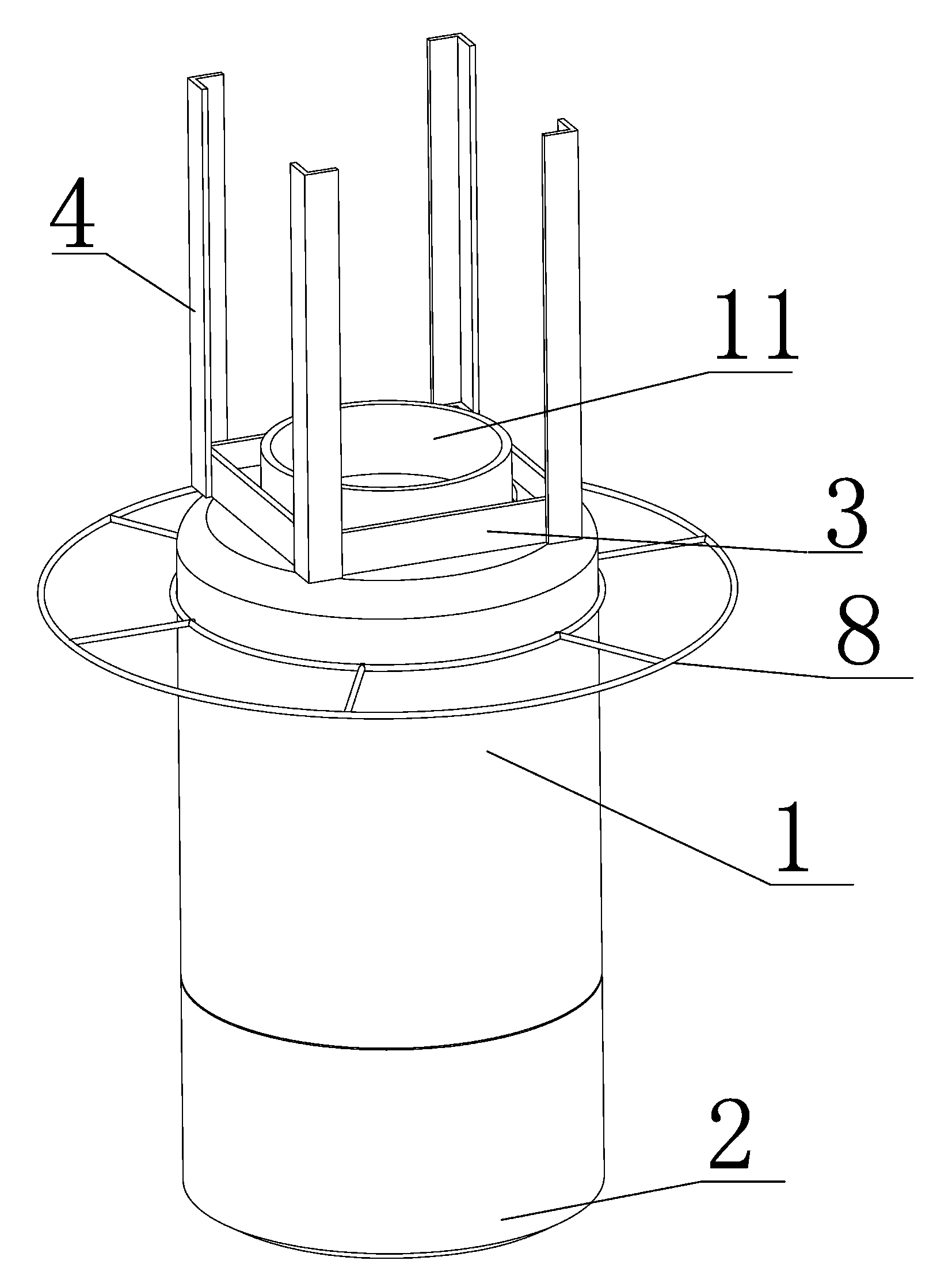

[0033] Embodiment 2 of the assembly mode of the present invention: use the exhaust module in the present invention directly as a range hood, the specific way is to install a fixed bracket outside the air guide pipe 11 of the exhaust module, and install a collector on the main pipe 1 through the fan cover bracket 8 Smoke hood 7 directly hangs and installs the exhaust module on the wall 72 above the stove through the angle iron of the fixing bracket. In order to ensure the appearance, a decorative cover can be installed outside the angle iron, and the smoke port at the front end of the auxiliary pipe can be used to directly absorb the oil fume. The fume collecting cover can collect oil fume, prevent the spread of oil fume, and decorate and beautify the appearance of the exhaust module.

[0034] Therefore, compared with the traditional centrifugal fan range hood, the present invention avoids the need for flue gas to pass through the volute and the tortuous air duct, and reduces th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com