Inlet temperature control device of dust collector of production line

A technology of control device and inlet temperature, applied in furnace control device, furnace, lighting and heating equipment, etc., can solve the problems of aggravating the loss of dust collection equipment and unable to reduce the temperature of flue gas in time, to meet the needs of normal operation, automation High level, safe operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

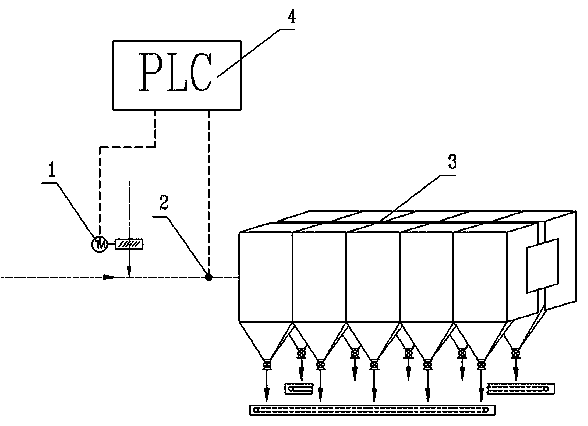

[0019] In the figure, a kind of dust collector inlet temperature control device in cement production is composed of the following parts:

[0020] 1. The air-cooled electric valve installed on the flue gas pipe before entering the dust collector;

[0021] 2. The temperature sensor installed on the flue gas pipe before entering the dust collector;

[0022] 3. The PLC temperature control system that automatically controls the opening of the cold air electric valve according to the temperature signal of the temperature sensor.

[0023] The above-mentioned PLC temperature control system consists of a temperature processing module, an analog expansion module, a PLC controller and a touch screen; the temperature processing module is connected to the temperature sensor installed on the flue gas pipe before entering the dust collector, and the PLC controller The control end is connected with the above-mentioned air-cooled electric valve.

[0024] The invention is a device for controlling the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com