A non-destructive floor material compression test method and its device

A test device, non-destructive technology, applied in the direction of applying stable tension/pressure to test the strength of materials, and using electrical devices to test fluid tightness, etc., can solve problems such as laborious, frequent repairs, laborious and time-consuming sample preparation, etc. Achieve the effect of improving efficiency and accuracy, saving integration time, and improving production defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

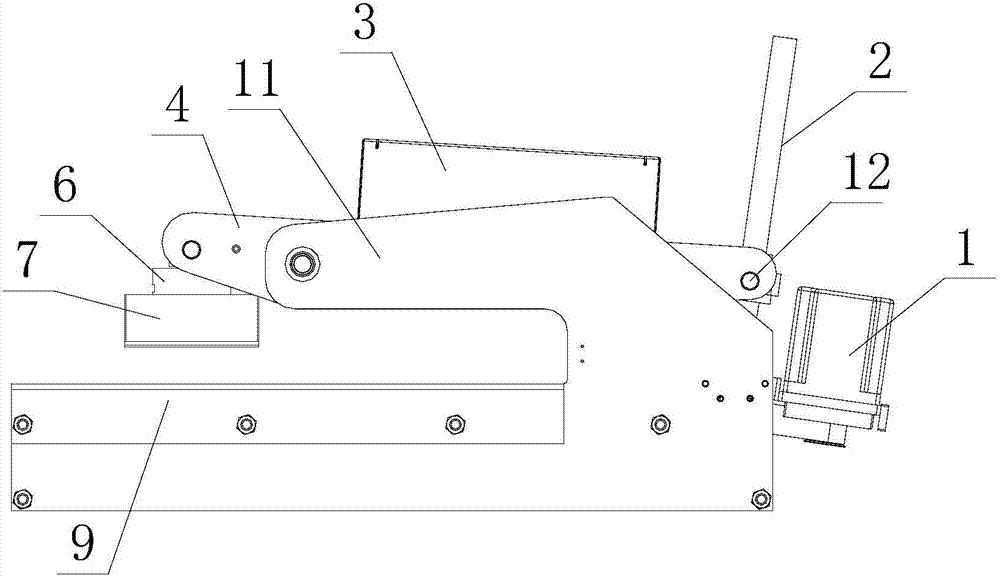

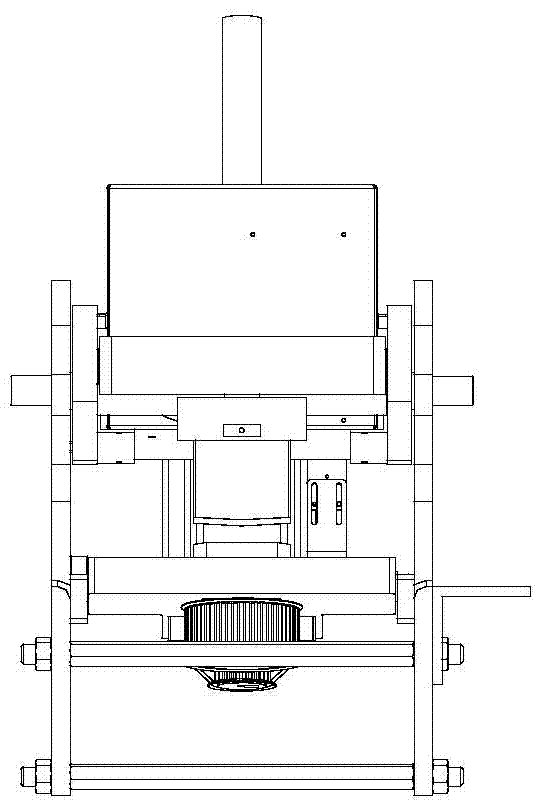

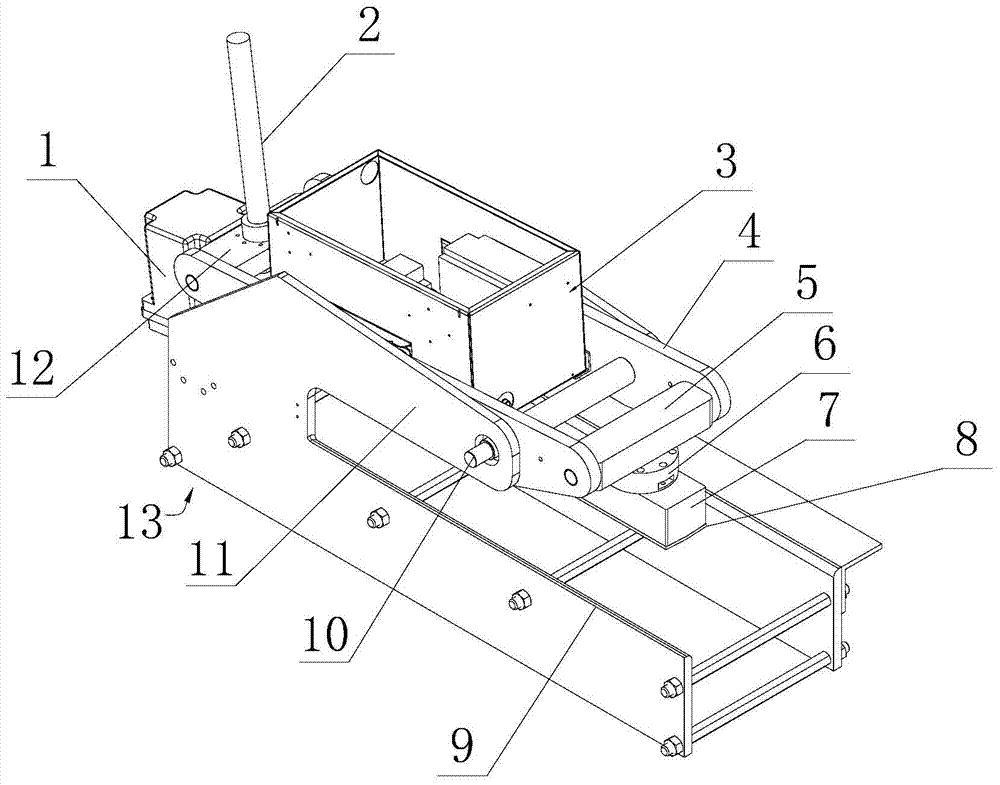

[0032] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0033] as attached Figure 1-3 As shown, the present invention comprises: servo motor 1, screw mandrel 2, frame 13 and control part, and described frame 13 is made up of test bench 9 and swing arm 11, and servo motor 1 is housed at the rear end of described test bench 9, The servo motor 1 is equipped with a reducer, the output shaft of the reducer is connected to the screw rod 2, and the screw rod 2 is connected to the lifting seat 12, and the two ends of the lifting seat 12 are connected to the lever bracket through the rotating pin 4, the lever bracket 4 is installed on the front end of the swing arm 11 through the fulcrum shaft 10, the front end of the lever bracket 4 is provided with a rotating support 5, and the bottom of the rotating support 5 is provided with a load cell 6 And the test pressure head 7, the pressure measurement surface of the test pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com