An Optical Proximity Correction Method

A technology of optical proximity and photolithography, applied in optics, optomechanical equipment, originals for optomechanical processing, etc., can solve the problems of product quality, impact on circuit performance, time-consuming and easy to miss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

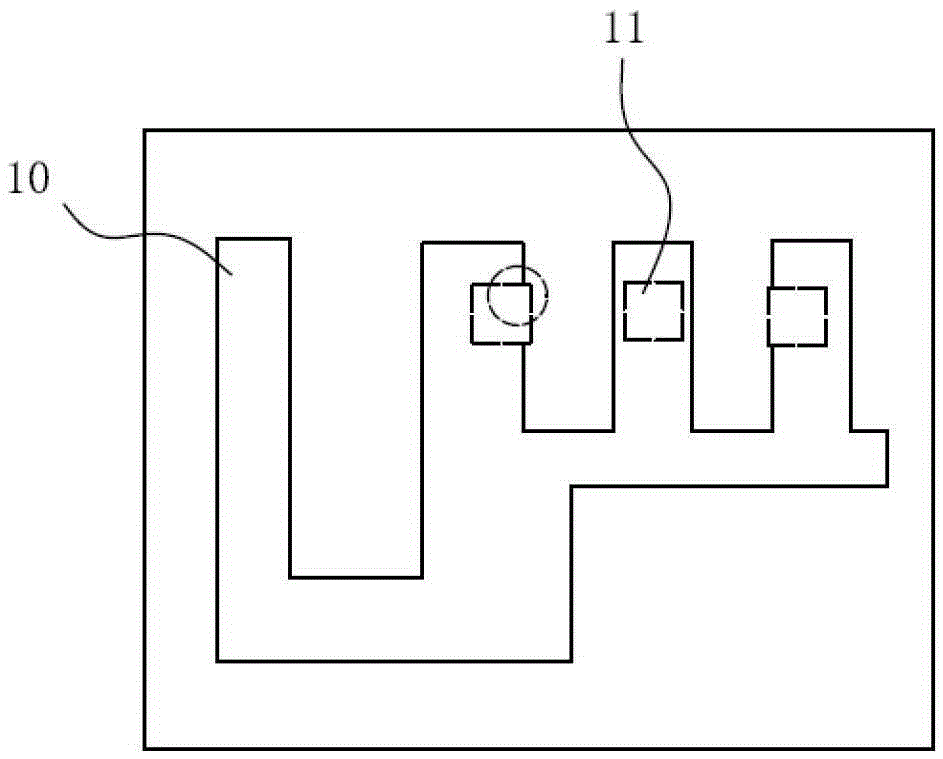

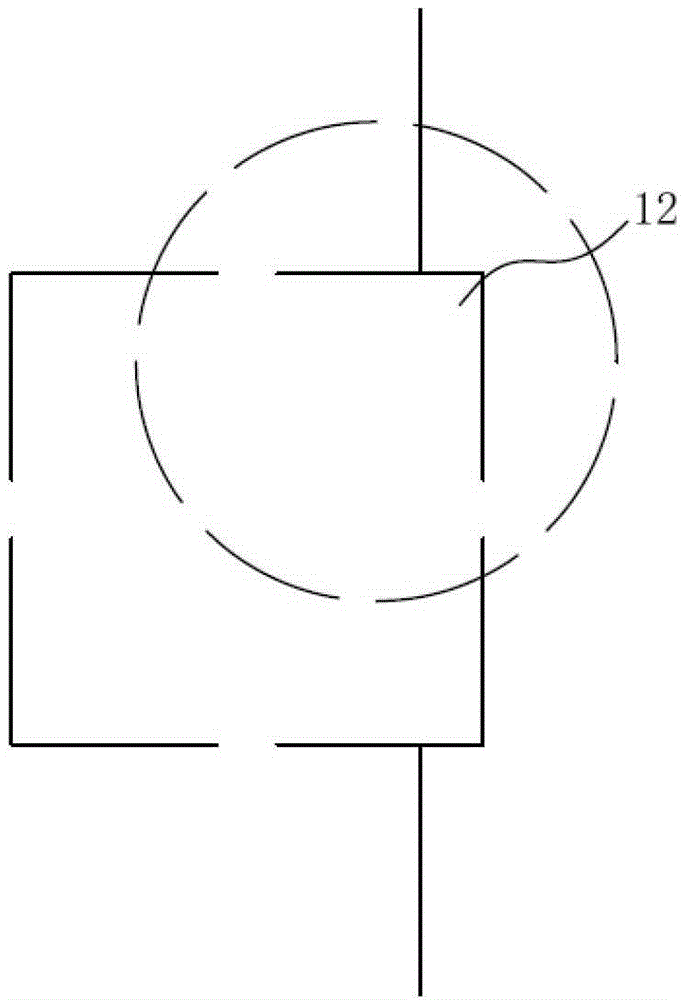

[0029] As mentioned in the background art, because in the An (metal wiring level), in order to cover holes used as conductive plugs, some metal lines may have bumps. In the existing OPC optimization processing program, there is no step of judging whether these protrusions are useful structures, so after the OPC optimization is completed, defects are often formed in these protrusions, and these defects not only destroy the metal The structural characteristics of the line itself, and on the contrary, further expose the place that originally needs to cover the hole, which seriously affects the quality of the device. Therefore, it is necessary to optimize the existing optical proximity correction method to avoid these defects and improve the quality of semiconductor devices.

[0030] The present invention aims at the above problems. In the existing OPC program, a cleaning program for the protrusions caused by covering holes is added. Before the OPC processing program is executed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com