Preparation method for low-fat stirred probiotics acidified milk

A stirring-type, probiotic technology, which is applied in the field of preparation of low-fat stirred-type probiotic fermented milk, can solve problems such as low-fat fermented milk flavor defects, achieve the effects of degrading cholesterol, saving enterprise costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

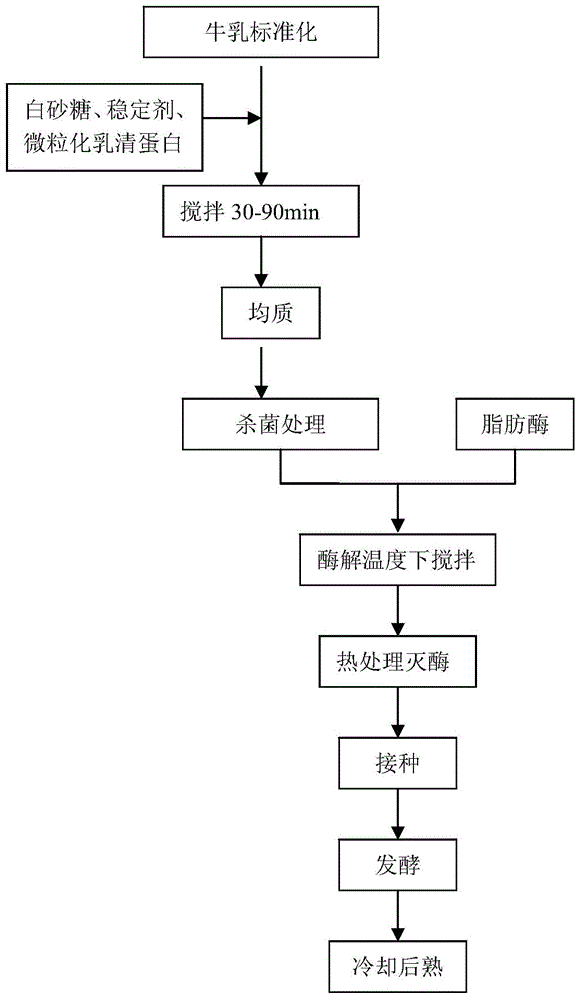

[0024] The invention provides a method for preparing low-fat stirred fermented milk, such as figure 1 shown, including the following steps:

[0025] (1) Mixing: Take the following raw materials in parts by weight: 85 parts of low-fat milk (the mass fraction of fat content is 0.8%), 9 parts of white sugar, 0.8 part of micronized whey protein, and 0.3 part of stabilizer; After mixing, stir at 55° C. for 90 min. The stabilizer is a mixture of xanthan gum, propylene glycol alginate, pectin and modified starch in a weight ratio of 1:3:2:1.

[0026] (2) Homogenization: Homogenize the feed liquid obtained in step (1) once at a temperature of 65°C, a primary pressure of 15 MPa, and a secondary pressure of 3 MPa.

[0027] (3) Sterilization: The feed liquid obtained in step (2) was sterilized at 95°C for 5 minutes, and then cooled to 40°C.

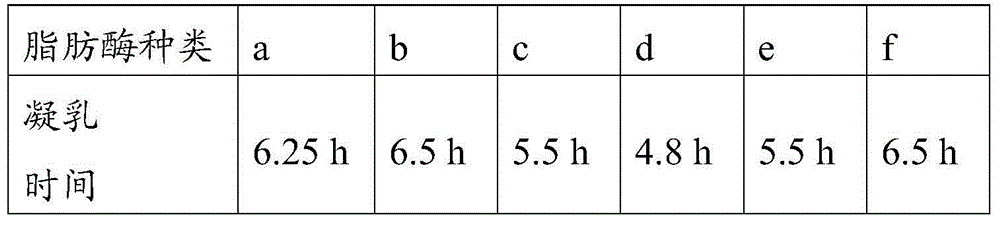

[0028] (4) Enzymolysis: Add lipase d to the feed liquid obtained in step (3), the amount of lipase added accounts for 0.5‰ of the feed liquid ma...

Embodiment 2

[0033] Embodiment 2 Comparison of the effects of low-fat fermented milk prepared under different parameter conditions by the method of the present invention

[0034] Table 1 Sensory scoring criteria

[0035] flavor

Fraction

Bitter taste compared with control group

0-2

Compared with the control group, it has a slightly bitter taste

2-4

Compared with the control group, it has a very slight bitter taste

4-6

Compared with the control group, the milk flavor is slightly stronger

6-8

Compared with the control group, the milk flavor is stronger

8-10

[0036] The prepared low-fat fermented milk was post-ripened in a refrigerator at 4°C for 24 hours, and the sensory evaluation was carried out.

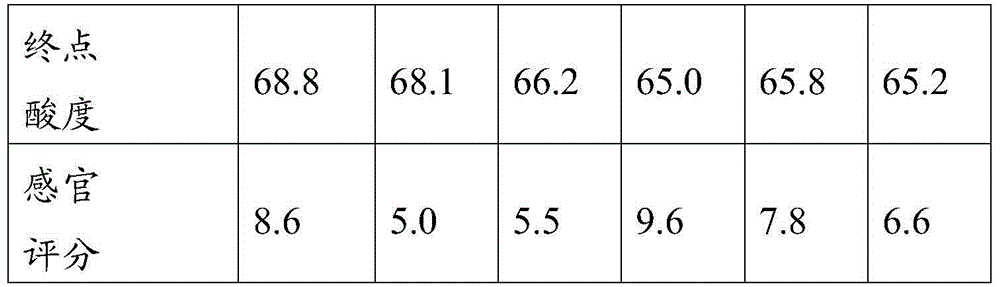

[0037] One, with the preparation method of low-fat stirring type fermented milk described in embodiment 1, as table 2 is the sensory evaluation when the milk fat content after standardization is respectively 0.8, 1.0%, 1...

Embodiment 3

[0055] The invention provides a method for preparing low-fat stirred fermented milk, which comprises the following steps:

[0056] (1) Mixing: Take the following raw materials in parts by weight: 90 parts of low-fat milk (the mass fraction of fat content is 1.5%), 8 parts of white sugar, 1 part of micronized whey protein, and 0.7 parts of stabilizer; After mixing, stir at 70°C for 30 minutes.

[0057] (2) Homogenization: Homogenize the feed liquid obtained in step (1) once at a temperature of 65°C, a primary pressure of 18MPa, and a secondary pressure of 3MPa.

[0058] (3) Sterilization: The feed liquid obtained in step (2) was sterilized at 95°C for 10 minutes, and then cooled to 42°C.

[0059] (4) Enzymolysis: Add lipase c to the feed liquid obtained in step (3), the amount of lipase added accounts for 0.3‰ of the feed liquid mass fraction, and enzymatic hydrolysis at 42°C for 30 minutes.

[0060] (5) Enzyme inactivation: Heat the feed liquid obtained in step (4) to 85°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com