High-expansion foam generator

A high-expansion foam and generator technology, applied in fire rescue and other directions, can solve the problems of difficult to meet the fire extinguishing in super large space, poor system reliability, complex pipe network system, etc. The effect of bubble area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

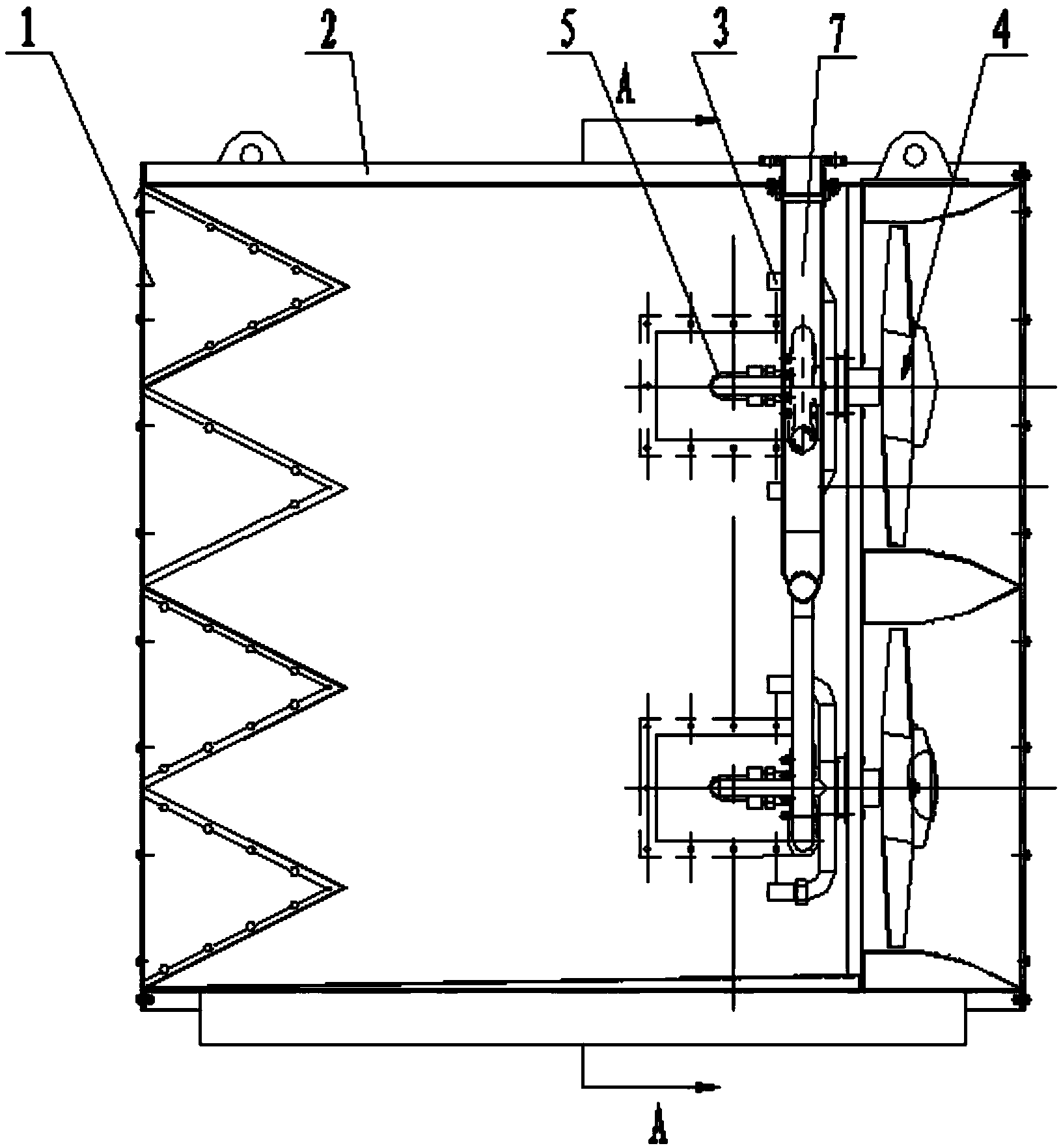

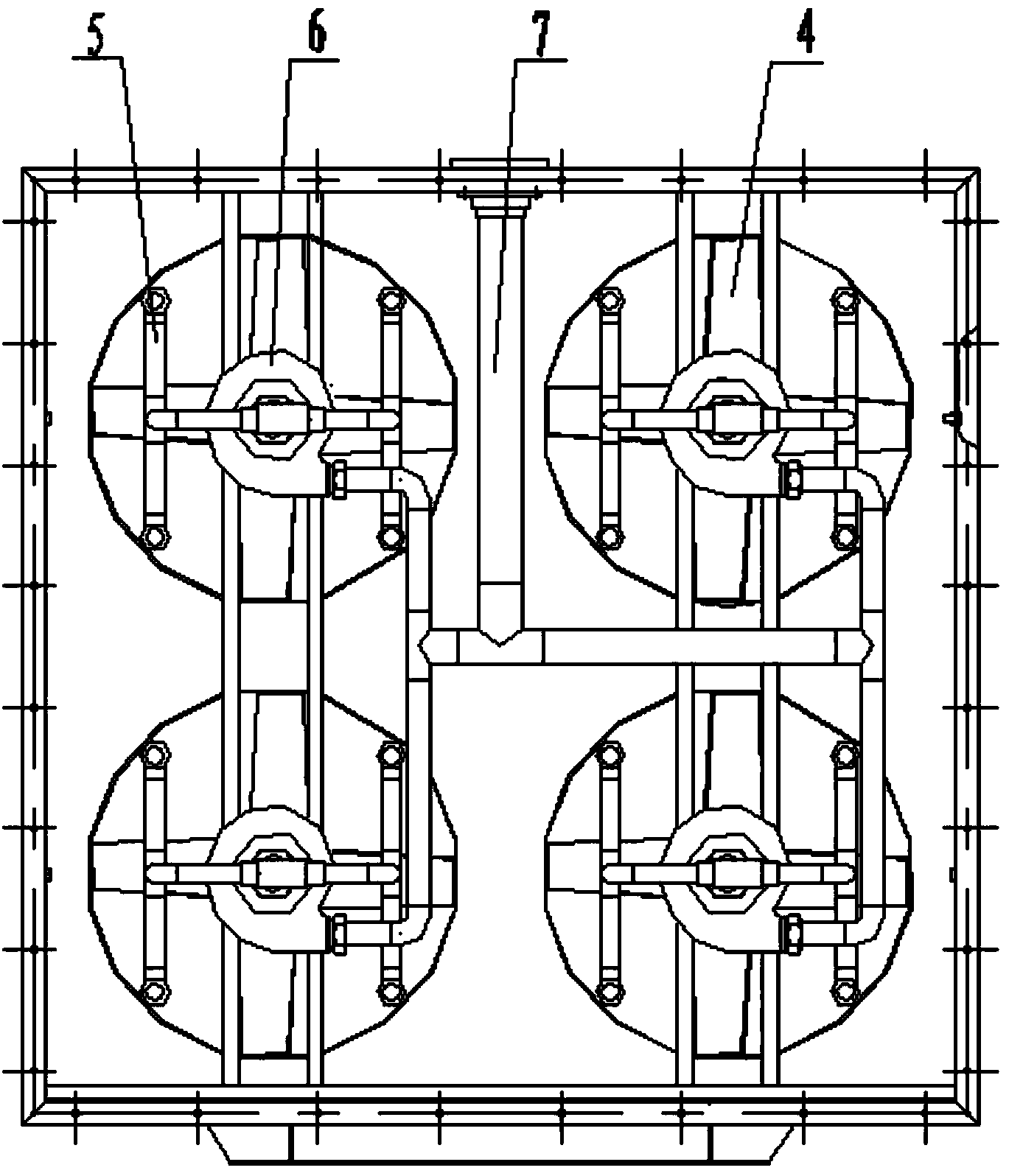

[0016] Such as figure 1 with figure 2 As shown, the high-expansion foam generator provided by the present invention is provided with a sawtooth-shaped orifice foaming net foaming net 1 at one end of the cylindrical shell 2, and the other end of the foaming net 1 is arranged in the shell 2 There is a water turbine 6, and the wind vane impeller 4 is connected to the main shaft of the water turbine 6 through a key. The center outlet of the water turbine 6 is respectively provided with a nozzle 3 through a branch pipe 5, and the tangential inlet of the water turbine 6 is respectively connected to the main pipe of the external foam liquid supply system through a pipeline. 7 are connected, and the wind direction of the fan blade impeller 4 points to the foaming net 1.

[0017] Such as figure 2 As shown, the branch pipe 5 and the nozzle 3 connecting the nozzle 3 and the center outlet of the water turbine 6 are evenly arranged in the cross section of the casing 2, so that a balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com