Mariculture wastewater treatment method and mariculture wastewater treatment system for higher-place pond

A technology for marine aquaculture and wastewater treatment, which is applied in the fields of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

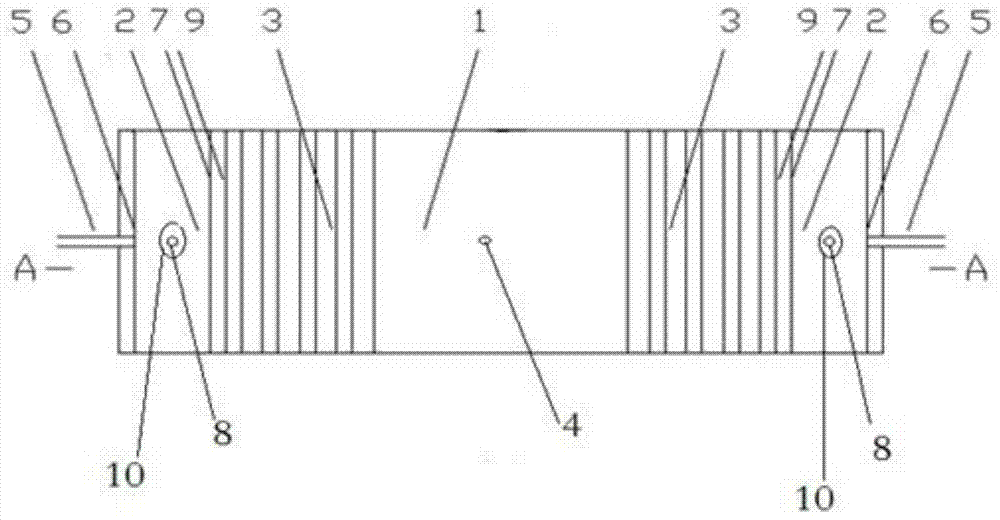

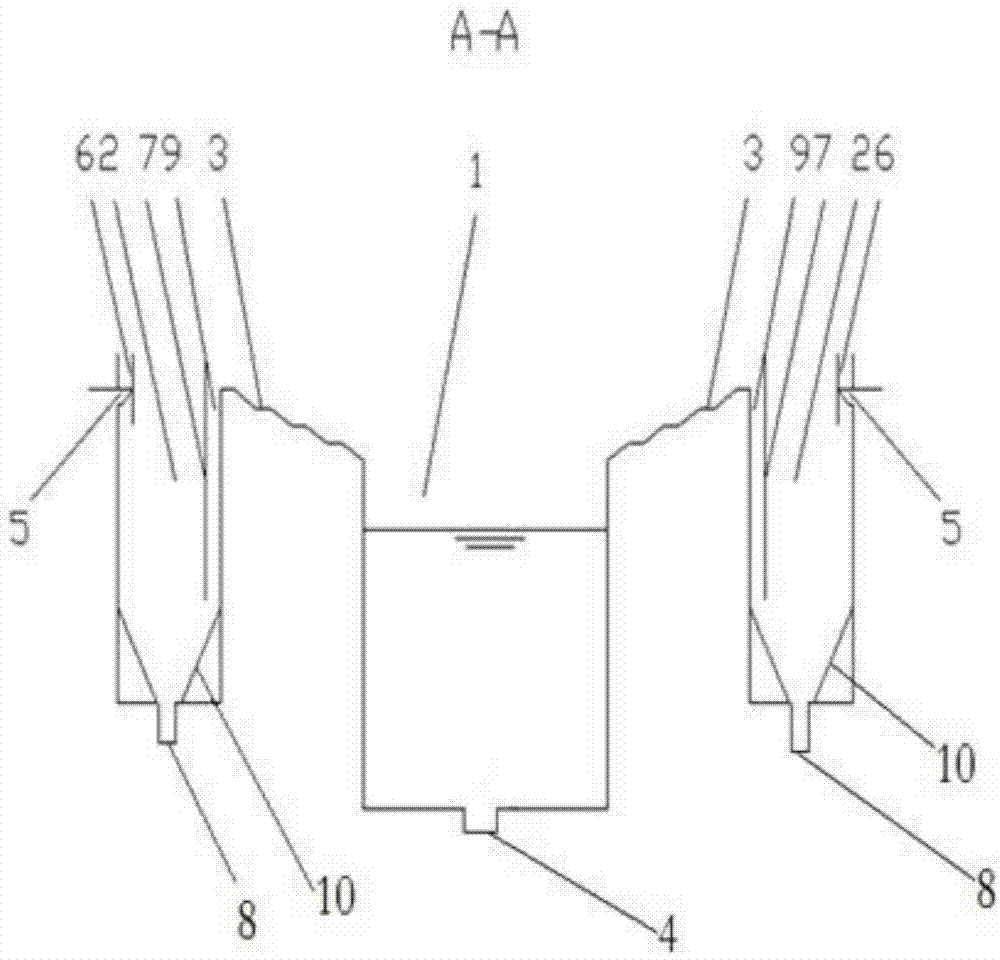

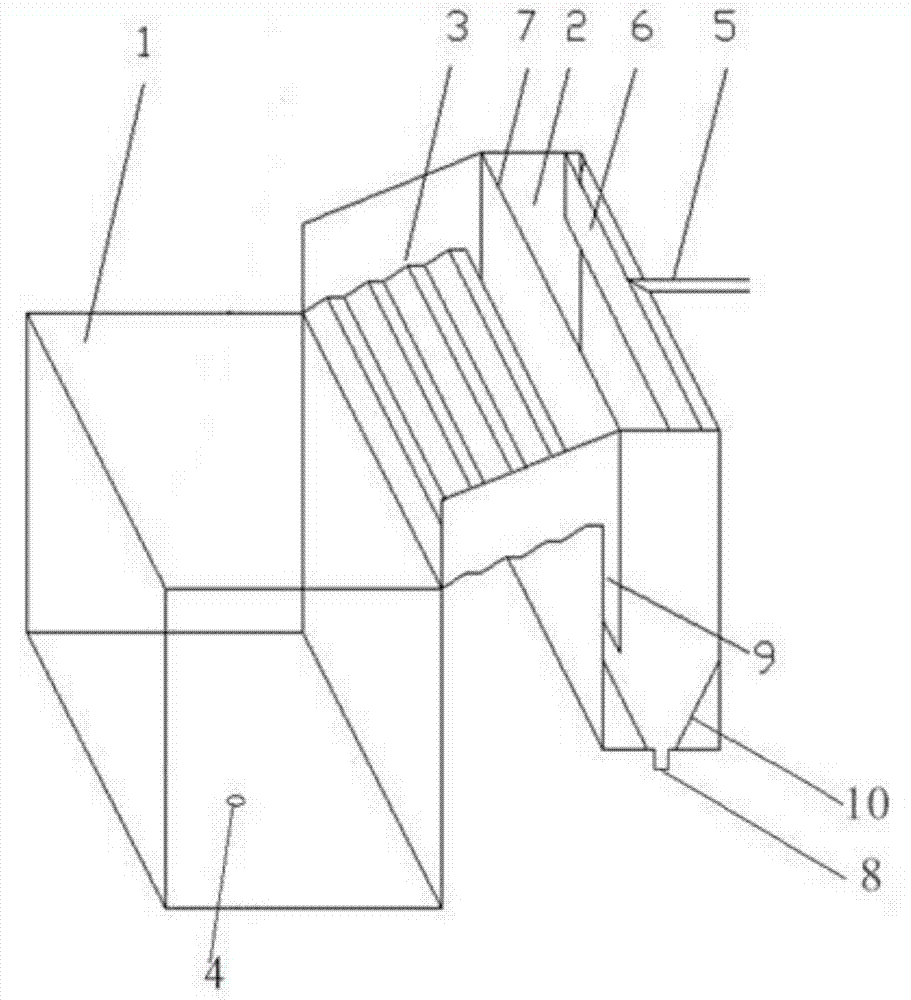

[0033] Such as figure 1 , figure 2 , image 3 Shown: Shellfish and shrimp are placed in a 5.0m×5.0m×5.0m (length×width×height) elevated tank 1 for polyculture, and the waste water produced is under the action of the pump, from the outlet pipe 4 to the inlet pipe 5 Enter the chrysanthemum heart Gracilaria culture tank 2 through the water inlet baffle 6, wherein the size of the culture tank 2 is 5m×0.5m×1.0m (length×width×height), the length of the water inlet baffle 6 is 5m, and the water inlet baffle The plate 6 is flush with the top of the culture tank 2 and the lower part is suspended in the air and fixedly connected with the culture tank 2. The distance between the lower edge of the water inlet baffle plate 6 and the bottom of the culture tank 2 is 0.8m. Utilize Gracilaria chrysanthemum to absorb most of COD, N, P and other pollutants and intercept SS. SS settles in the trapezoidal mud storage bucket 10 and is regularly discharged from the mud outlet pipe 8. The height o...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3Shown: Shellfish and fish are placed in a 5m×5m×5m (length×width×height) high level tank 1 for polyculture, and the waste water generated passes through the water inlet from the outlet pipe 4 to the inlet pipe 5 under the action of the pump The baffle plate 6 enters the deformed culture tank 2 of Gracilaria spp., wherein the size of the culture tank 2 is 5m×0.7m×2.0m (length×width×height), the length of the water inlet baffle 6 is 5m, and the water inlet baffle The plate 6 is flush with the top of the culture tank 2 and the lower part is suspended, and the distance between the lower edge of the water inlet baffle plate 6 and the bottom of the culture tank 2 is 1.6m. Utilize Gracilaria chrysanthemum to absorb most of COD, N, P and other pollutants and intercept SS. SS settles in the trapezoidal mud storage bucket 10 and is regularly discharged from the mud discharge pipe 8. The height of the trapezoidal mud storage bucket 10 is 0....

Embodiment 3

[0037] Such as figure 1 , figure 2 , image 3 Shown: Shellfish and crabs are placed in a 5m×4m×3m (length×width×height) elevated tank 1 for polyculture, and the generated waste water flows from the outlet pipe 4 to the inlet pipe 5 under the action of the pump. The water baffle 6 enters the culture tank 2 of Sargassum grassa and Kappa longista, wherein the size of the culture tank 2 is 5m×1.0m×3.0m (length×width×height), and the length of the water inlet baffle 6 is 5m , the water inlet baffle 6 is flush with the top of the culture tank 2 and the lower part is suspended, and the distance between the lower edge of the water inlet baffle 6 and the bottom of the culture tank 2 is 2.4m. Utilize Gracilaria chrysanthemum to absorb most of COD, N, P and other pollutants and intercept SS. SS settles in the trapezoidal mud storage bucket 10 and is regularly discharged from the mud outlet pipe 8. The trapezoidal mud storage bucket 10 is 0.75m in height, and The angle between the mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com