A kind of preparation method of wide molecular weight distribution homopolypropylene resin

A wide molecular weight distribution, homopolymerized polypropylene technology, applied in the field of polypropylene resin preparation, to achieve the effect of wide molecular weight distribution, easy processing, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

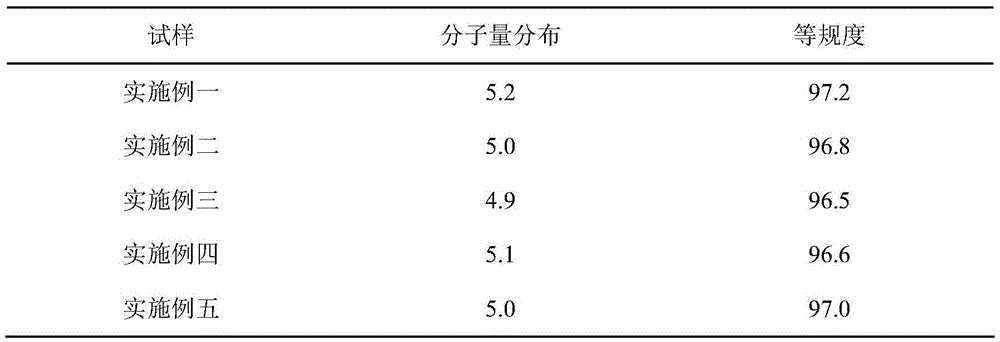

Embodiment 1

[0018] In the single-loop polypropylene unit of LBI’s Spheripol process, a new type of wide molecular weight distribution catalyst NDQ (NDQ catalyst is provided by Sinopec Catalyst Beijing Aoda Branch) is used to produce average molecular weight distribution (Mw / Mn=4.0~5.5). The polypropylene base resin has a melt index of 10-15g / 10min, and a homopolypropylene resin is produced by adding a high-efficiency additive system. The high-efficiency additive system is expressed in parts by weight. The wide molecular weight distribution homopolypropylene resin raw material is 100 parts, the auxiliary additive antioxidant is 10100.06 parts, the auxiliary additive antioxidant is 1680.03 parts, the auxiliary additive calcium stearate is 0.03 parts, and the auxiliary additive GMS is (Glyceryl monostearate) 0.09 parts, 0.21 parts in total, add to a high-speed mixer and mix thoroughly, first mix at 750r / min for 1 minute, then mix at 1500r / min for 30 seconds, then add twin-screw extruder The ...

Embodiment 2

[0020] In the single-loop polypropylene unit of LBI company Spheripol process, wide molecular weight distribution catalyst NDQ is used to produce homopolymer polypropylene resin with wide molecular weight distribution (Mw / Mn=4.0-5.5), and the melt index is 11-12g / 10min , and then a homopolymerized polypropylene resin is produced by adding a high-efficiency additive system. The high-efficiency additive system is expressed in parts by weight. The wide molecular weight distribution homopolypropylene resin raw material is 100 parts, the auxiliary additive antioxidant is 10100.06 parts, the auxiliary additive antioxidant is 1680.03 parts, the auxiliary additive calcium stearate is 0.06 part, and the auxiliary additive GMS is (Glyceryl monostearate) 0.11 parts, 0.26 parts in total, add to a high-speed mixer and mix thoroughly, first mix at 450r / min for 1 minute, then mix at 1200r / min for 30 seconds, then add twin-screw extruder The granulation is carried out in the machine, and the ...

Embodiment 3

[0022] In the single-loop polypropylene unit of LBI company Spheripol process, wide molecular weight distribution catalyst NDQ is used to produce homopolymer polypropylene resin with wide molecular weight distribution (Mw / Mn=4.0-5.5), and the melt index is 12-13g / 10min , and then a homopolymerized polypropylene resin is produced by adding a high-efficiency additive system. The high-efficiency additive system is expressed in parts by weight. The wide molecular weight distribution homopolypropylene resin raw material is 100 parts, the auxiliary additive antioxidant is 10100.06 parts, the auxiliary additive antioxidant is 1680.03 parts, the auxiliary additive calcium stearate is 0.06 part, and the auxiliary additive GMS is (Glyceryl monostearate) 0.09 parts, 0.24 parts in total, add to a high-speed mixer and mix thoroughly, first mix at 550r / min for 1 minute, then mix at 1300r / min for 30 seconds, then add twin-screw extruder The granulation is carried out in the machine, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com