Stone drying mucilage glue installing structure and installing method

A technology of installation structure and installation method, applied in building construction, covering/lining, construction, etc., can solve problems such as unsafe dry hanging, inability to construct, insufficient dry hanging stone slab thickness, etc. Efficiency, the effect of widening the effective use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

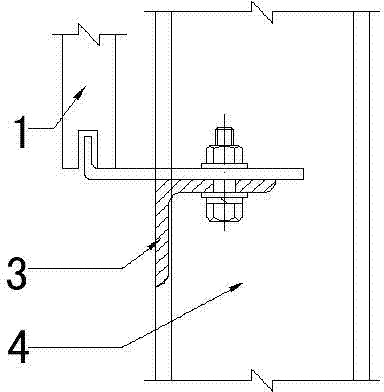

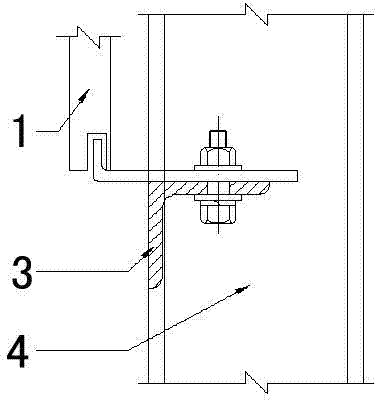

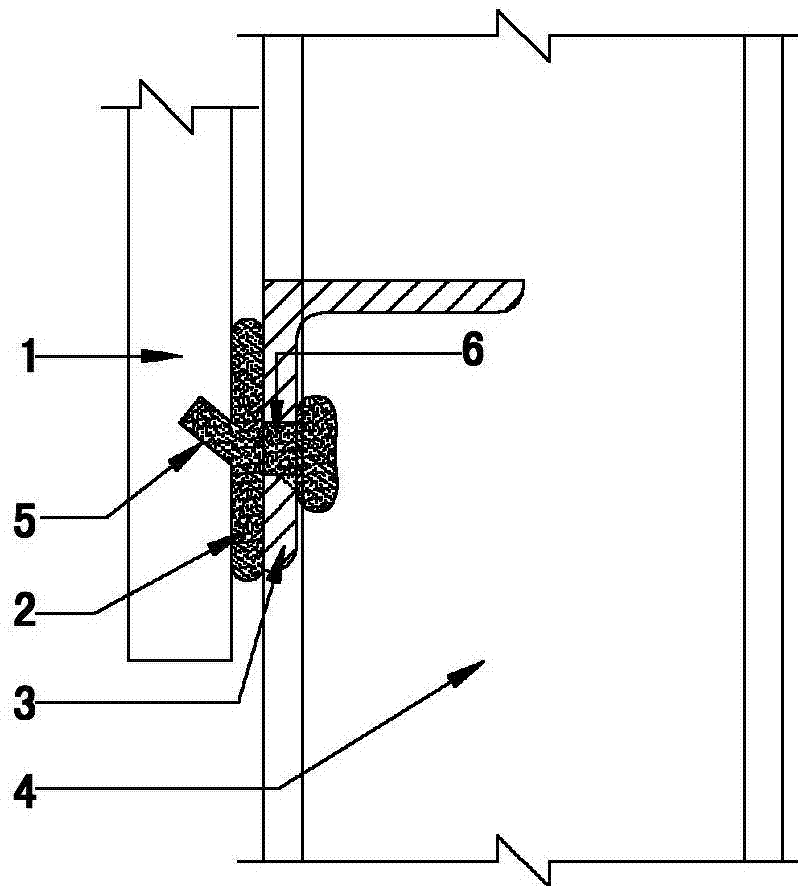

[0018] Example one: such as image 3 As shown, a dry-adhesive and dry-hanging structure of stone includes stone 1, dry glue 2, horizontal keel 3, and vertical keel 4. The glue tank 5 is an inclined upward groove from outside to inside, and the cross section of the horizontal keel 3 is L-shaped.

[0019] The horizontal keel 3 is connected to the vertical keel 4 fixed on the wall; both the horizontal keel 3 and the vertical keel 4 can be effectively connected in various ways. The back of the stone 1 is opened with a glue groove 5, and the dry glue 2 is poured into the inside to form a physical connection; the horizontal keel 3 and the stone contact surface are opened with a glue hole 6, and the stone 1 passes through the dry glue 2 in the glue groove 5 and penetrates. The glue-through hole 6 is fixed by a glue nail formed on the back of the horizontal keel 3, and the glue-through hole 6 facilitates the dry glue 2 to pass through the glue hole 6 through the horizontal keel 3 to for...

Embodiment 2

[0020] Embodiment 2: A dry-bonding installation method of stone, which includes the following steps:

[0021] a. There is a glue pot 5 on the back of the stone 1, and the glue pot 5 is an inclined upward groove from outside to inside. The contact part between the horizontal keel 3 and the stone 1 is provided with a plastic hole 6.

[0022] b. Bond the stone 1 and the horizontal keel 3 with dry glue 2.

[0023] c. In the uncured state, part of the dry glue 2 penetrates into the glue groove 5 on the back of the stone 1, and forms a glue nail structure in the glue groove 5 after curing, and the other side penetrates the glue hole 6 of the horizontal keel 2 The post-expansion is attached to the reverse side of the horizontal keel 3, and the glue nail structure is formed after solidification. The two-sided glue nail structure forms a physical connection, and the adhesive force of the stone 1 and the horizontal keel 3 will work together after the expansion of the dry glue 2 , The stone 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com