Temporary plugging and energizing treatment method for heavy oil steam-stimulated wells

A processing method and steam technology, which are applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of high cost, single effect and large amount of consumption, and achieve low cost, simple construction and strong pertinence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

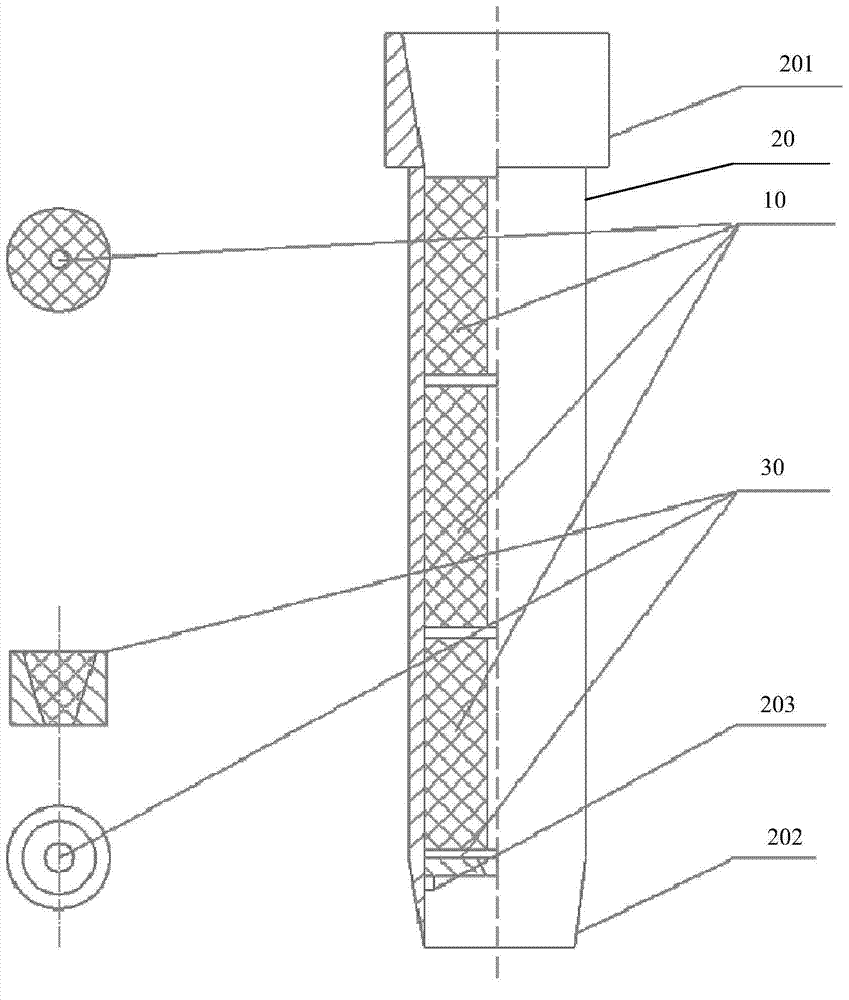

[0059] First, see figure 1 Shown is a downhole feeder for transporting solid temporary plugging material 10 used in the method of the present invention. The downhole feeder mainly includes a pipe body 20 (in this embodiment, a standard 4-inch oil pipe with a length of 1-3m), the pipe body is a space for accommodating the solid temporary plugging material 10, and the upper end of the pipe body is provided with a female buckle Hoop 201, a male buckle 202 is arranged at the lower end of the pipe body, and a limit steel ring 203 for load bearing is welded inside the pipe body near the male buckle 202. The height of the limit steel ring (longitudinal in the figure) is about 10mm, and the thickness 2 ~ 3mm.

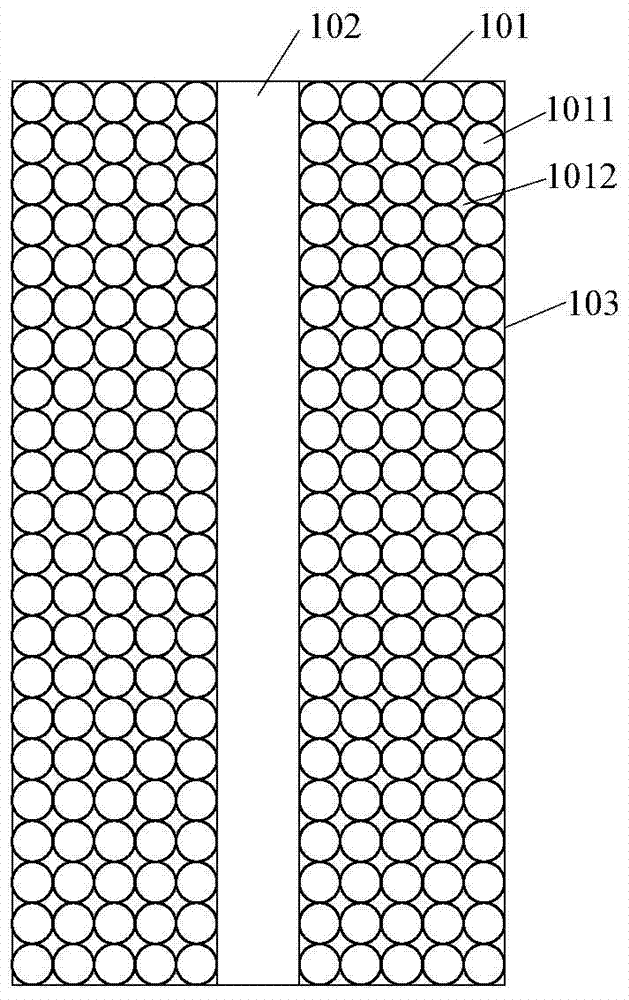

[0060] The solid temporary plugging material 10 in this embodiment, its structure see figure 2 As shown, it mainly includes a cylindrical body (body 101 of solid temporary plugging material) formed by stacking a plurality of resin balls 1011, and a through hole ( The throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com