Pneumatic control system of bearing service life tester

A technology of pneumatic control system and bearing life, which is applied in the directions of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of unfavorable experimental accuracy of testing machine, waste of production cost, large device error, etc. To achieve excellent flow performance, simple and convenient operation, reduce the effect of joints and pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

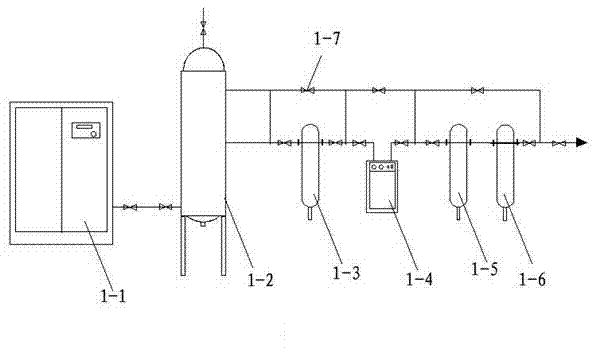

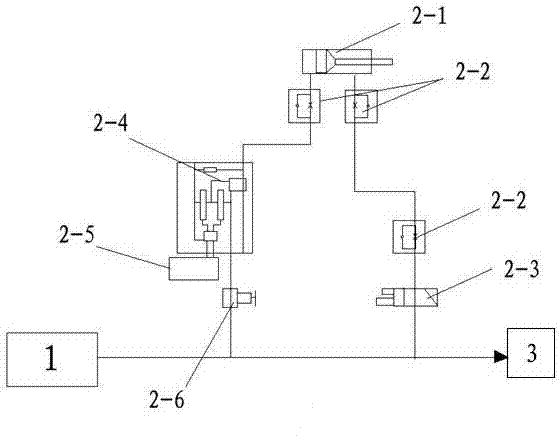

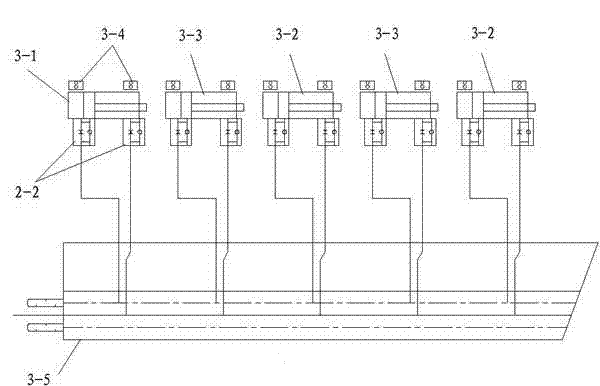

[0022] Example 1: Such as figure 1 , 2 A pneumatic control system of a bearing life testing machine shown in and 3, the pneumatic control system includes an air supply system 1 and an air assembly, and the air assembly includes a pneumatic system 2 of the transmission device and a temperature control box pneumatic System 3, the pneumatic system 2 of the transmission device includes a force cylinder 2-1, a pressure sensor 2-5 and a precision pressure reducing valve 2-6, and the pressure sensor 2-5 is connected to the On the force cylinder 2-1, a precision pressure relief valve 2-6 is provided on the connecting pipeline between the force cylinder 2-1 and the air supply system 1, and the temperature control box pneumatic system 3 includes a large cover Cylinder 3-1, two compact cylinders 3-3 and two guide cylinders 3-2, the five cylinders are connected in parallel on the air supply system through the valve guide structure 3-5.

[0023] The working pressure of the air circuit ...

Embodiment 2

[0025] Example 2: Such as image 3 As shown, the pneumatic system 3 of the temperature control box is installed on the temperature control box 4, the two compact cylinders 3-3 are installed on the upper part 4-3 of the temperature control box, and the two guide cylinders 3-2 are installed At the bottom 4-2 of the temperature control box, the large uncovered cylinder 3-1 is installed on the back 4-1 of the temperature control box. Different cylinders control the opening and closing of the movable doors at different positions on the temperature control box, and the device has a high degree of automation. , Simple and convenient operation, the stroke of each cylinder of the temperature control box pneumatic system 3 according to the present invention is controlled by the magnetic switches 3-4 located at both ends of the cylinder.

Embodiment 3

[0026] Example 3: Such as figure 1 As shown, the air supply system 1 is connected to the air storage tank 1-2, the main pipeline dust filter 1-3, and the refrigerated drying box 1-4 in sequence by the air compressor 1-1 through the pipeline and the valve 1-7. , the main line oil-water filter 1-5 and the high-efficiency degreasing filter 1-6 are connected to the air-consuming components through the high-efficiency degreasing filter 1-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com