Mixed gas charging device for high-voltage electrical equipment

A technology for high-voltage electrical equipment and mixed gas, which is applied to equipment, mechanical equipment, gas/liquid distribution and storage in pressure vessels, etc. It can solve the problem of not being able to mix and inflate a large amount at one time, and achieve easy implementation and simple pipelines. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

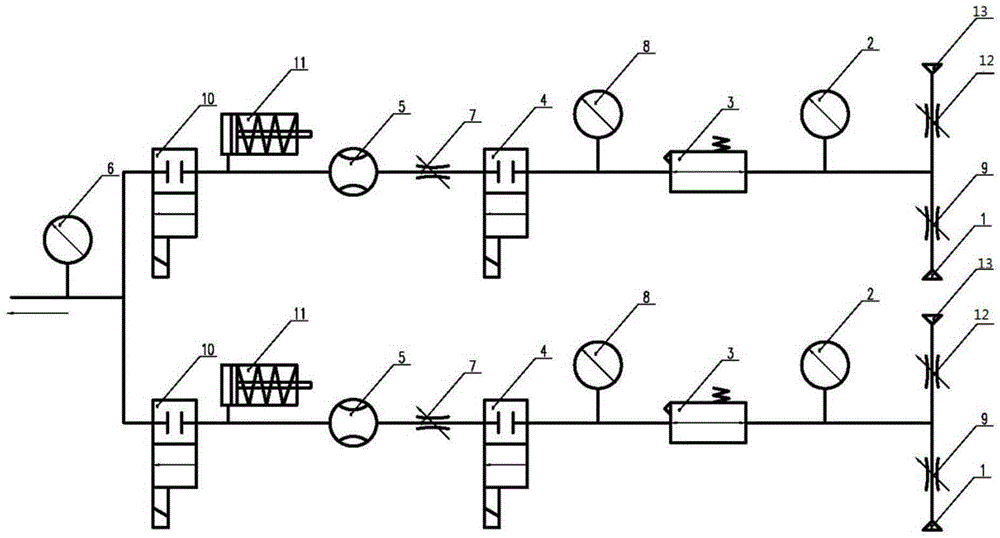

[0021] Such as figure 1 Shown is the structural diagram of the embodiment of the mixed gas charging device for high-voltage electrical equipment of the present invention. It can be seen from the figure that the device includes at least two charging branches with an inlet end and an outlet end, and each charging branch is from the inlet end to the The air outlet end is provided with a pressure regulating unit and an air charging unit in sequence, and the air outlet end of each air charging branch is connected with the main air charging pipeline used to connect the air chamber; the air charging unit includes the first throttle valve 7, the gas flow meter 5 and the Inflatable solenoid valve 10, a cylinder 11 is connected to the charging branch between the first throttle valve 7 and charging solenoid valve 10, and the air inlet of the cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com