Method for building lubricating oil film model after thermal coupling deformation of static pressure center frame

A thermal-mechanical coupling and lubricating oil film technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve optimal design, improve service life, and avoid lubrication failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

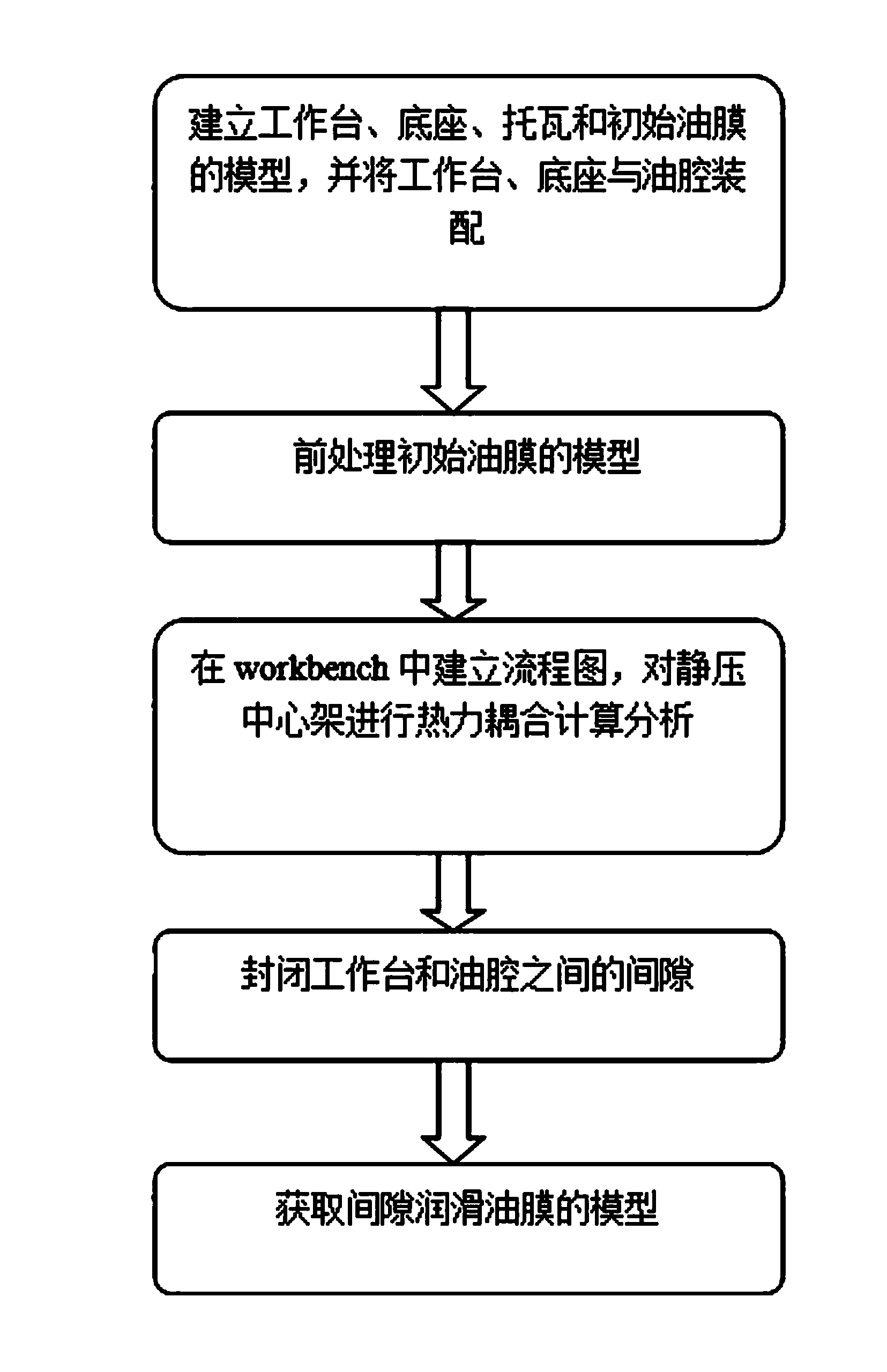

[0028] Specific implementation mode 1: Referring to each figure, a method for establishing a lubricating oil film model after thermomechanical coupling deformation of a hydrostatic steady rest in this embodiment is implemented in the following steps:

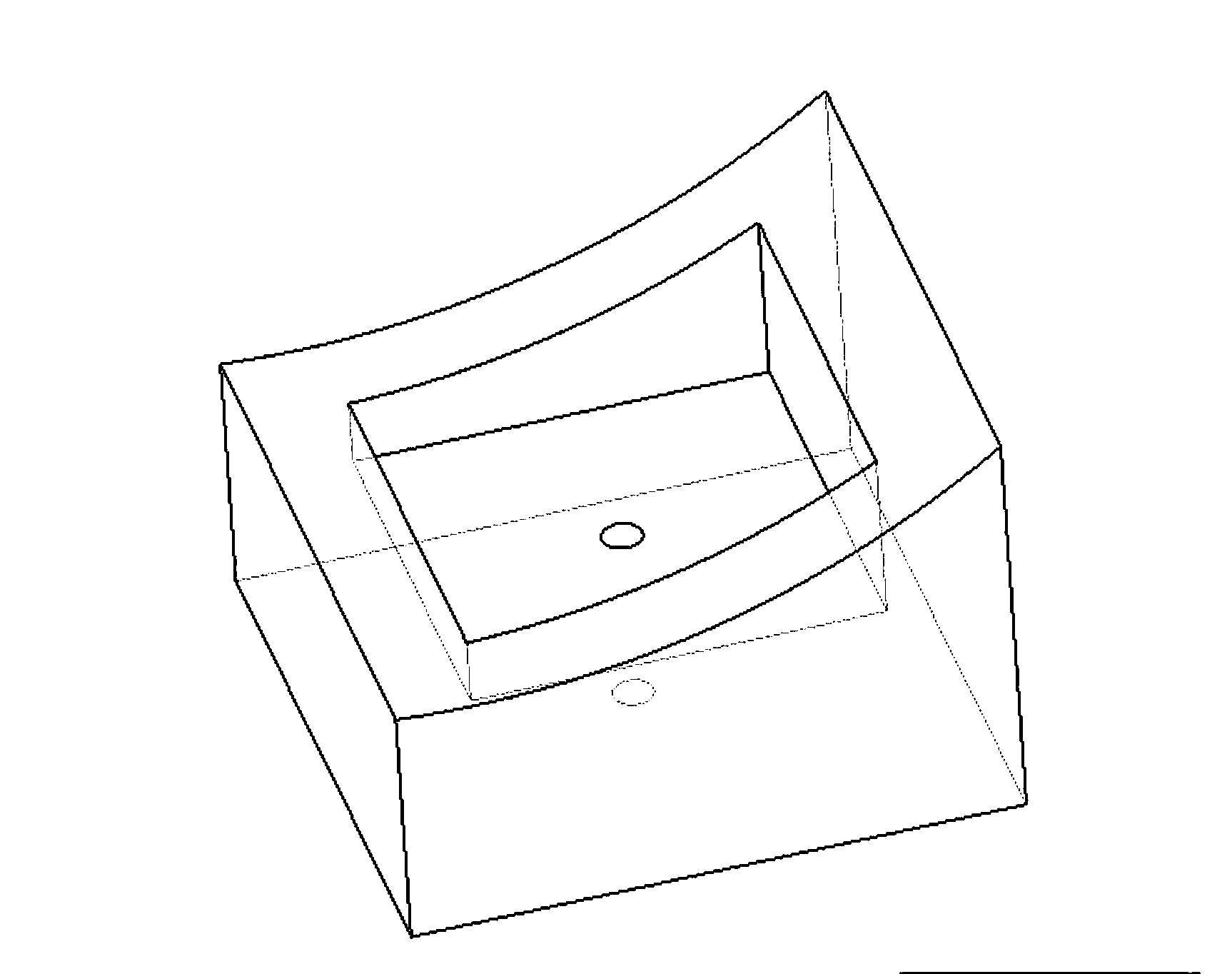

[0029] Step 1. According to the size structure of the test machine tool and the given initial oil film thickness, use UG to build the model of the workbench, base, support block and initial oil film, assemble the support block, workbench, base and oil chamber, and export it to zhengtizhuangpei. x_t and chushiyoumo.x_t files;

[0030] Step 2. Use CFD software to mesh the initial oil film to obtain a high-quality mesh, specify the boundary conditions of the fluid domain and output the chushiyoumo.fluent5 / 6mesh file, and import the chushiyoumo.fluent5 / 6mesh file into FLUENT to input or select the oil film inlet temperature T in Initial value, initial value of oil film fixed wall surface temperature, oil film inlet flow rate Q, ou...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the workbench and the base are analyzed using a 1 / 4 model, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

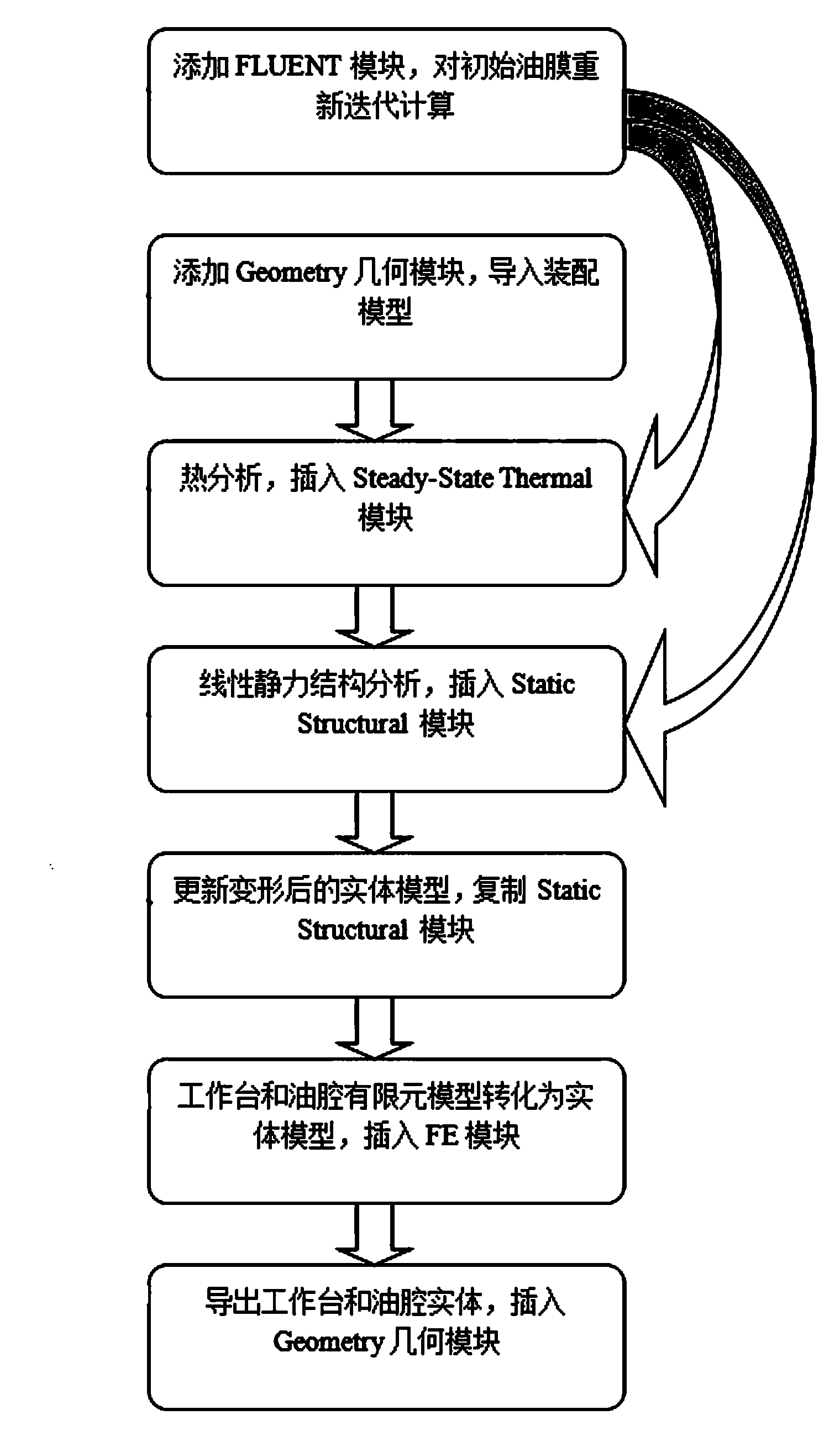

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: Step 3 establishes a work flow chart in ANSYS WOERKBECH software, and performs thermomechanical coupling calculation and analysis on the static pressure steady rest as follows:

[0036] Step 3-1. Import the fluid analysis results, add the FLUENT module, import the chushiyoumo.cas file in step B into FLUENT and re-calculate iteratively;

[0037] Step 3-2. Import the assembly model, add the Geometry module, and import the zhengtizhuangpei.x_t file in step A;

[0038]Step 3-3, thermal analysis, insert the Steady-State Thermal module, and set the material properties of the workbench, base and oil chamber. Since only thermal analysis and linear structural analysis are required, it is only necessary to fill in the corresponding density in the material property window , Young's modulus, Poisson's ratio, and thermal conductivity; import the results of fluid analysis int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com