Irradiation crosslinked polyolefin elastic insulation and sheath rubber soft cable

A cross-linked polyolefin and flexible cable technology, applied in insulated cables, insulated conductors, organic insulators, etc., can solve the problems of affecting product quality, blackening of conductor surfaces, high pollution in boiler rooms, etc. The effect of prolonging the service life and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

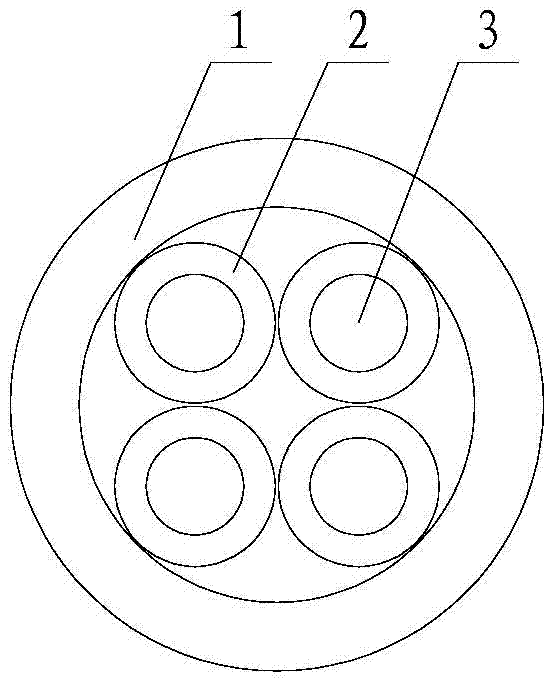

[0016] An irradiation cross-linked polyolefin elastic insulation and sheath rubber sheath flexible cable, including an outer sheath 1 and a plurality of conductor cores, each conductor core is composed of a conductor 3 and an insulating layer 2 wrapped on the outer surface of the conductor , the conductor is an oxygen-free copper wire conductor, and the insulating layer is an insulating layer of radiation cross-linked polyolefin elastomer. A plurality of conductor cores are wrapped together on the inner side of the outer sheath, and the outer sheath is an outer sheath of radiation cross-linked polyolefin elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com