Dry grind ethanol production process and system with front end milling method

A production process and dry grinding technology, applied in biochemical equipment and methods, liquid production bioreactors, biofuels, etc., can solve the problem of not being able to remove fine solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

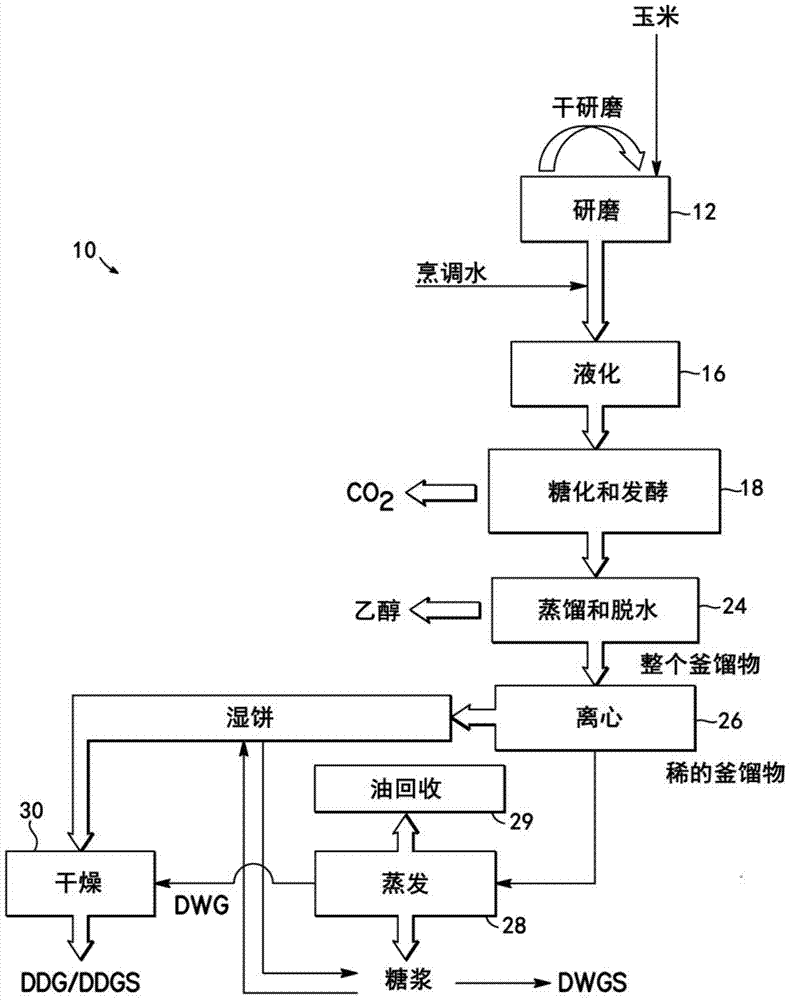

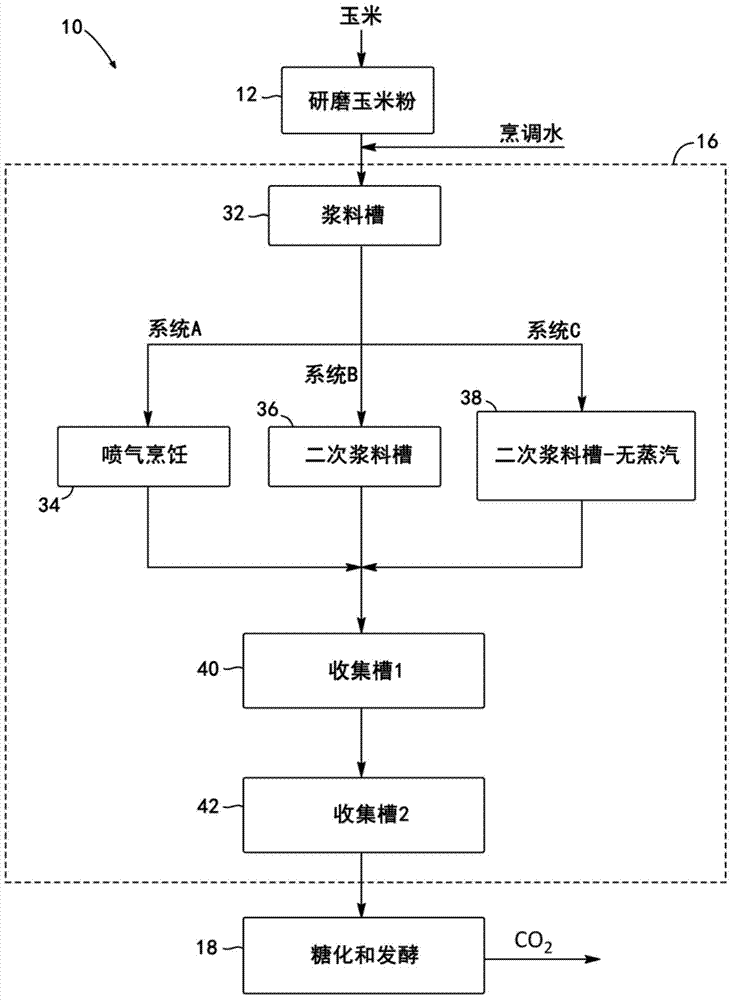

[0039] Figures 1 and 2 have been discussed above and represent, respectively, a typical dry grind ethanol production process and flow diagrams of various typical liquefaction processes defining liquefaction steps in the dry grind ethanol production process.

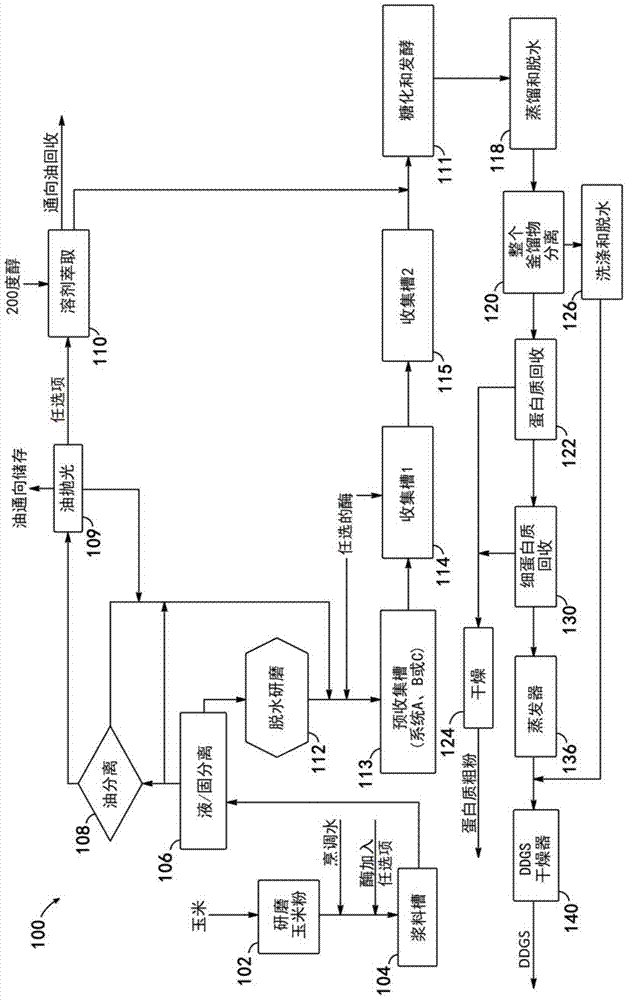

[0040] Figure 3-9B Various embodiments of dry milled ethanol production processes and systems using front-end milling methods are illustrated for improved alcohol, oil and / or protein yields and for the production of pure, more desirable fibers, such as for secondary alcohol production . These processes and systems are discussed in detail below.

[0041] first reference image 3 , which depicts a flow diagram of an embodiment of a dry milled ethanol production process and system using a front-end milling approach for improved alcohol and / or by-product yield (eg, oil and / or protein yield). In the process 100, corn first undergoes a grinding step 102, which involves the use of a hammer mill or the like, to grind the corn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com