Method for extracting aluminum from aluminum-containing minerals

A mineral and bauxite technology, applied in the field of aluminum extraction, can solve problems such as easy decomposition, affecting aluminum leaching rate, and affecting leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

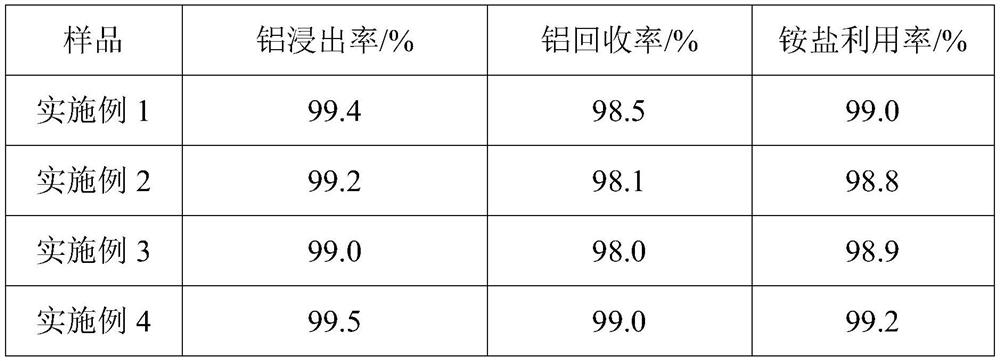

Embodiment 1

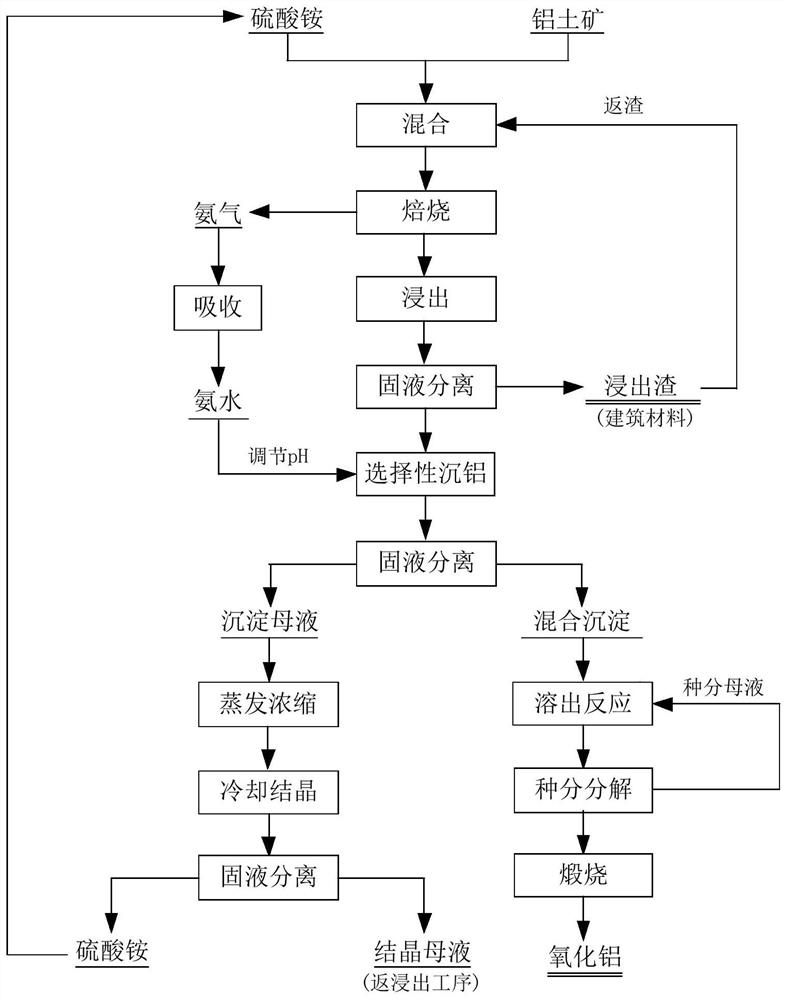

[0093] This embodiment provides a method for extracting aluminum from bauxite, the process flow diagram of the method is as follows figure 1 shown, including the following steps:

[0094] (1) The bauxite is dried, crushed and ball milled successively to obtain a particle size of 200 mesh powdered bauxite, which is then mixed with ammonium sulfate. The mass ratio of the bauxite to ammonium sulfate is 1:4. Calcining in an atmosphere with a water vapor volume fraction of 60% and an air volume fraction of 40%, the roasting temperature is 450° C., and the roasting time is 120 minutes to obtain roasted clinker and tail gas. The tail gas includes ammonia gas, which is absorbed by water to obtain ammonia water;

[0095] (2) The roasted clinker obtained in step (1) is mixed with water for leaching, the leaching temperature is 90°C, the leaching pH is controlled at 2.0, the leaching time is 120min, the liquid-solid ratio of leaching is 4mL / g, and separated by filtration to obtain Leach...

Embodiment 2

[0101] This embodiment provides a method for extracting aluminum from bauxite, said method comprising the following steps:

[0102] (1) The bauxite is dried, crushed and ball milled successively to obtain a particle size of 600 mesh powdered bauxite, which is then mixed with ammonium sulfate. The mass ratio of the bauxite to ammonium sulfate is 1:6. Roasting in an atmosphere with a water vapor volume fraction of 10% and an air volume fraction of 90%, the roasting temperature is 350° C., and the roasting time is 250 minutes to obtain roasted clinker and tail gas, the tail gas including ammonia gas, which is absorbed by water to obtain ammonia water;

[0103] (2) The roasted clinker obtained in step (1) is mixed with water for leaching, the leaching temperature is 60°C, the leaching pH is controlled at 1.5, the leaching time is 200min, and the liquid-solid ratio of leaching is 10mL / g, separated by filtration to obtain Leaching solution and leaching slag, the leaching slag is par...

Embodiment 3

[0109] This embodiment provides a method for extracting aluminum from bauxite, said method comprising the following steps:

[0110] (1) The bauxite is dried, crushed and ball milled successively to obtain a particle size of 400 mesh powdered bauxite, which is then mixed with ammonium bisulfate, and the mass ratio of the bauxite to ammonium bisulfate is 1:9 , roasting in an atmosphere with a water vapor volume fraction of 90% and an air volume fraction of 10%, the roasting temperature is 250°C, and the roasting time is 350min, to obtain roasted clinker and tail gas, which includes ammonia gas and is obtained after absorbing with water ammonia;

[0111] (2) The roasted clinker obtained in step (1) is mixed with water for leaching, the leaching temperature is 120°C, the leaching pH is controlled at 2.5, the leaching time is 60min, the liquid-solid ratio of leaching is 2mL / g, centrifuged to obtain Leaching solution and leaching slag, the leaching slag is partially returned to ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com