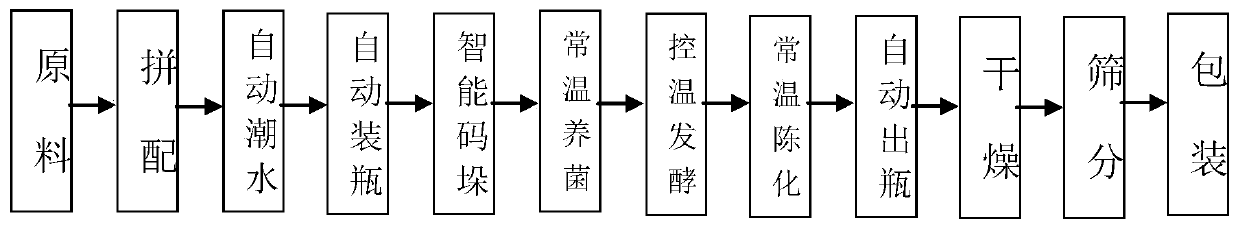

Whole-course non-toppling Pu'er tea fermentation process

A fermentation process and technology of Pu'er tea, applied in the field of tea processing, can solve the problems of turbid soup color, accelerated soup color turning brighter, and large volume, etc., and achieve the effect of increasing old fragrance, clear soup color, and obvious characteristics and advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1, select the sun-dried green hair tea obtained after the big-leaf tea is finished, kneaded and dried;

[0050] Step 2, sun-drying green tea tide water: tea leaves and water are tide-watered through automatic tide water equipment, so that the raw tea water content reaches 35%;

[0051] Step 3, bottling and palletizing according to the specification of 1000g / bottle, palletizing 4-7 layers;

[0052] Step 4, bacteria cultivation stage: room temperature: 20-30°C, humidity: 30%, time: 5d;

[0053] Step 5, fermentation stage: temperature: 40°C, humidity: 50%, time: 10d;

[0054] Step 6, aging stage: temperature: 20-30°C, humidity: 30%, time: 10d;

[0055] Step 7, bottle discharge: the material is discharged through the automatic bottle discharge machine;

[0056] Step 8, drying: After the material is out of the bottle, dry it at 40°C for 4 hours, and stop when the moisture drops to about 10%;

[0057] Step 9, screening: refining and screening the dried materials;

...

Embodiment 2

[0061] Step 1, select the sun-dried green hair tea obtained after the big-leaf tea is finished, kneaded and dried;

[0062] Step 2, raw tea tide water: tea leaves and water are tide-watered through automatic tide water equipment, so that the raw tea water content reaches 40%;

[0063] Step 3, bottling and palletizing according to the specification of 1000g / bottle, palletizing 6-10 layers;

[0064] Step 4, bacteria cultivation stage: room temperature: 20-30°C, humidity: 50%, time: 10d;

[0065] Step 5, fermentation stage: temperature: 40°C, humidity: 60%, time: 15d;

[0066] Step 6, aging stage: temperature, normal temperature: 20-30°C, humidity: 50%, time: 10d;

[0067] Step 7, bottle discharge: the material is discharged through the automatic bottle discharge machine;

[0068] Step 8, drying: After the material is out of the bottle, dry it at 50°C for 4 hours, and stop when the moisture drops to about 10%;

[0069] Step 9, screening: refining and screening the dried mater...

Embodiment 3

[0073] Step 1, select the sun-dried green hair tea obtained after the big-leaf tea is finished, kneaded and dried;

[0074] Step 2, raw tea tide water: tea leaves and water are tide-watered through automatic tide water equipment, so that the raw tea water content reaches 45%;

[0075] Step 3, bottling and palletizing according to the specification of 1000g / bottle, palletizing 8-15 layers;

[0076] Step 4, Bacteria cultivation stage: room temperature: 20-30°C, humidity: 80%, time: 10d;

[0077] Step 5, fermentation stage: temperature: 40°C, humidity: 80%, time: 15d;

[0078] Step 6, aging stage: temperature 20-30°C, humidity: 80%, time: 25d;

[0079] Step 7, bottle discharge: the material is discharged through the automatic bottle discharge machine;

[0080] Step 8, drying: After the material is out of the bottle, dry it at 65°C for 4 hours, and stop when the moisture drops to about 10%;

[0081] Step 9, screening: refining and screening the dried materials;

[0082] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com