Forage special for fattening pig

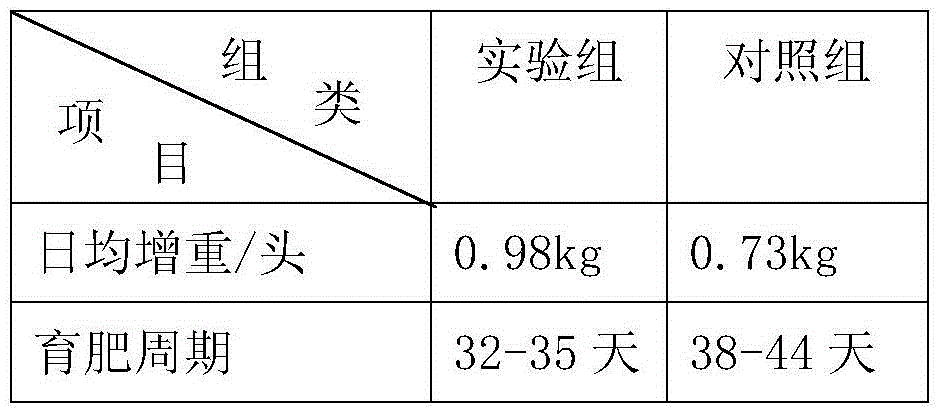

A fattening pig and feed technology, applied in the field of livestock breeding, can solve the problems of increased breeding cost, poor fattening effect, prolonged fattening cycle, etc., and achieve the effects of shortening the fattening cycle, increasing the slaughter rate, and accelerating weight gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] The pig feed of the present embodiment is made from the following raw materials in parts by weight: 80 parts by weight of corn, 25 parts by weight of rapeseed meal, 10 parts of rye, 15 parts of rice bran, 15 parts of dried distiller's grains, 15 parts of buckwheat bran, 10 parts of corn, 4 parts of dried fig powder, and soybean dregs 12. Dried bamboo shoots 8, chicken offal powder 4, plasma protein powder 5, earthworm powder 3, sweet potato leaves 8, sweet potato seedlings 5, appropriate amount of salt, food attractant 4, the food attractant consists of the following raw materials in parts by weight: coix seed oil 1. Barley grass powder 2, knuckle grass 3, Korean ginseng powder 2, vanilla powder 3, cinnamon 5, galangal 2, lovage 4, black cortex root 4, gerbera 4, papaya seed powder 8, sesame oil 30, Flour 35; the preparation method is to decoct cloves, cinnamon, galangal, lovage, black cortex, and gerbera with water for 1 hour, filter the decoction, condense it into a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com