Heavy-oil transfer oil storage tank with heating function

A technology for oil storage tanks and hot oil, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve problems such as delays in transportation and production, transportation losses, and hidden safety hazards, and achieve transportation time saving, no safety hazards, and shortened Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in conjunction with specific drawings and specific embodiments.

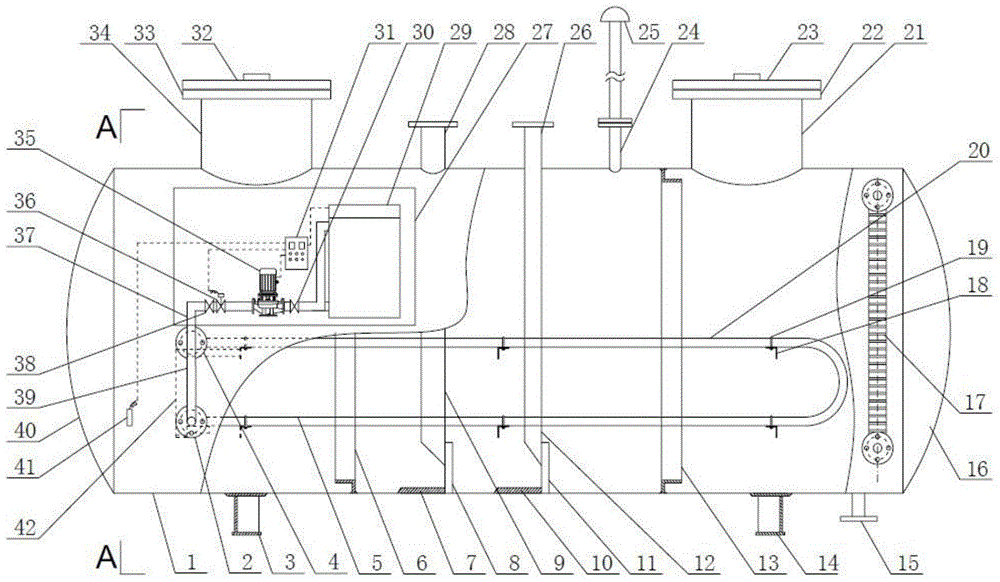

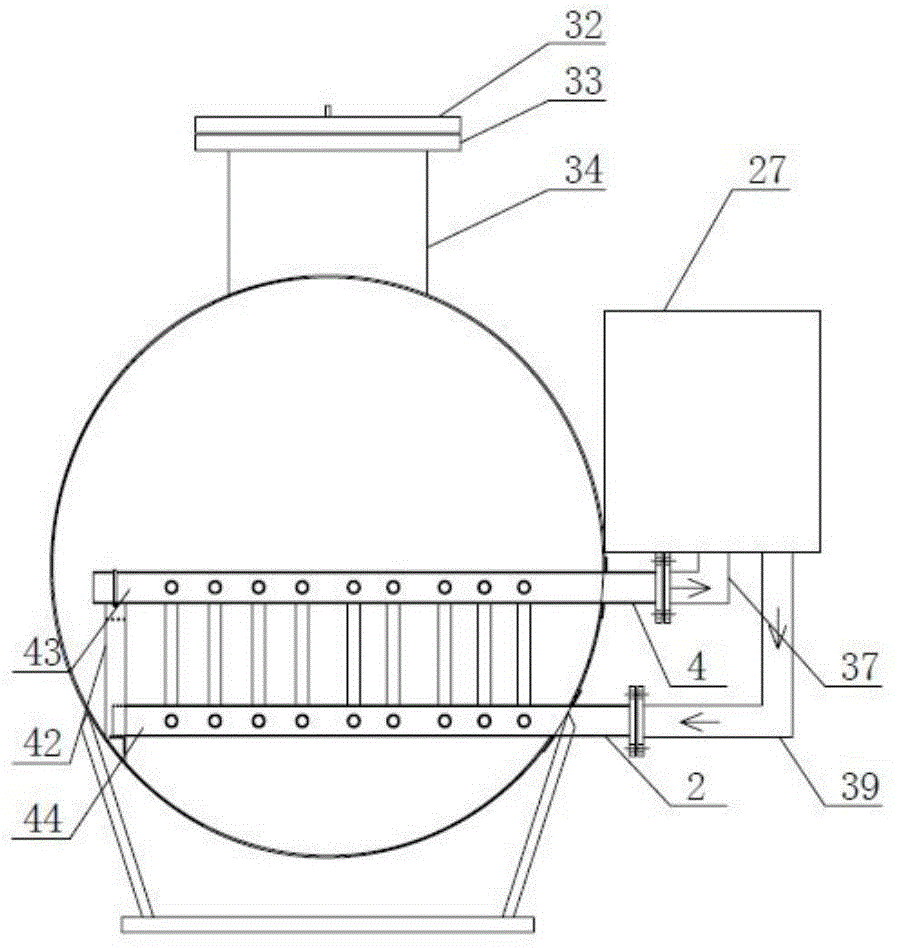

[0018] Such as figure 1 and figure 2 A heavy oil transfer storage tank with heating function is shown, including the tank body and the organic heat carrier heating unit installed in the tank body;

[0019] The organic heat carrier heating unit includes a heat source unit 27 and a horizontal U-shaped pipe heating oil heating tube bundle evenly distributed near the bottom of the oil tank;

[0020] The organic heat carrier heating unit is equipped with an organic heat carrier electric heating box 29, an output port of the organic heat carrier electric heating box 29 communicates with the pump body interface of the thermal oil circulation pump 35 through a connecting pipe, and the other of the thermal oil circulation pump 35 One side of the pump body interface is connected to the hot oil supply pipe 39, which is equipped with an automatic adjustment electric valve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap