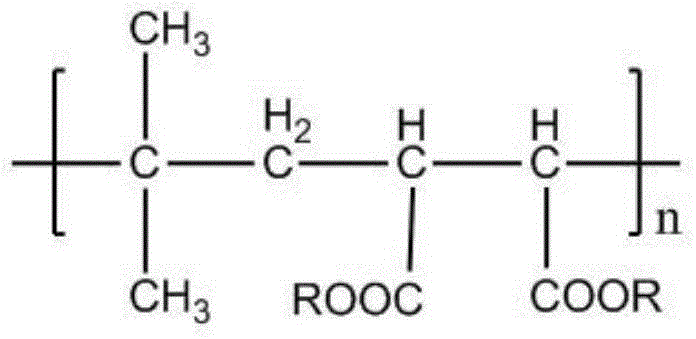

Polyisobutylene succinate, method for its preparation and use of the polyester to prepare microlubricating oil

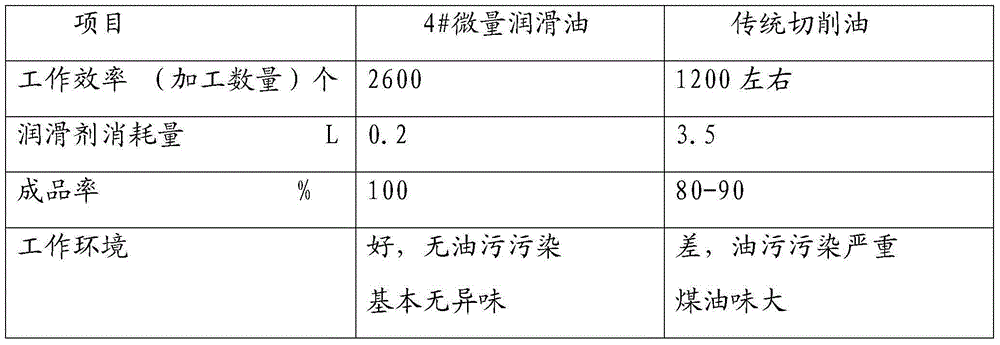

A technology of polyisobutylene succinate and butylene dioic acid, which is applied in the field of lubrication to achieve low pollution, reduce environmental and worker hazards, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

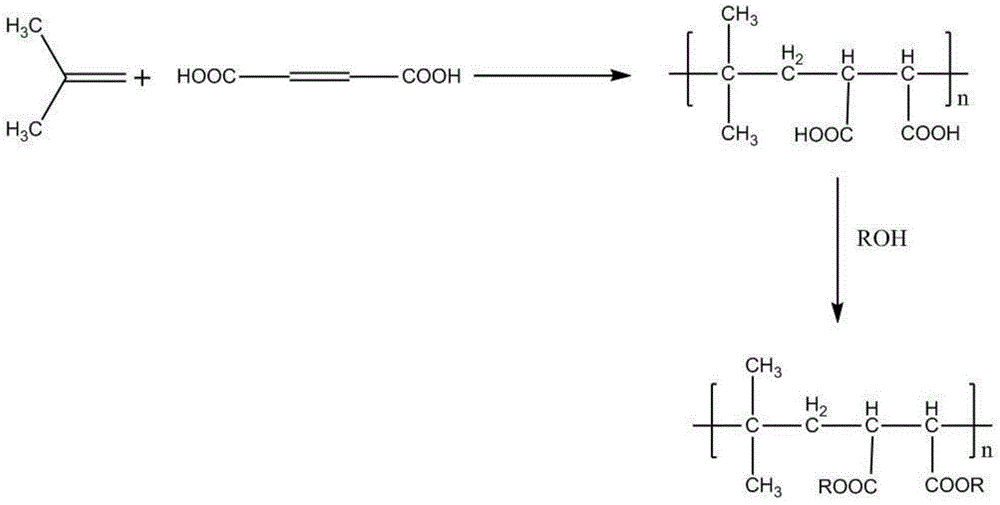

Method used

Image

Examples

Embodiment 1

[0046] 1# micro-quantity lubricating oil

[0047] Step 1: Put 148.24kg (2000mol) of isobutanol and 98.06kg (1000mol) of maleic anhydride (butenedioic anhydride) into the polymerization kettle respectively, and stir thoroughly;

[0048] Step 2: Put 0.74kg of initiator dibenzoyl peroxide (BPO) into the polymerization kettle;

[0049] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0050] Step 4: heat up to 80°C while stirring;

[0051] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0052] Step 6: Keep stirring at constant temperature for 12 hours after filling the isobutene gas;

[0053] Step 7: Add 6 kg of catalyst cation exchange resin to the polymerization kettle;

[0054] Step 8: heat up to 200°C, fully stir and react for 3 hours;

[0055] Step 9: remove moisture and unreacted isobutanol under reduced pressure;

[0056] Step te...

Embodiment 2

[0067] 2# Minimal quantity lubricating oil

[0068] Step 1: Put 192.71kg (2600mol) of n-butanol and 116.07kg (1000mol) of maleic acid (maleic acid) into the polymerization kettle respectively, and fully stir;

[0069] Step 2: Put 0.62kg of initiator dibenzoyl peroxide (BPO) into the polymerization kettle;

[0070] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0071] Step 4: heat up to 76°C while stirring;

[0072] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0073] Step 6: Keep stirring at constant temperature for 10 hours after filling the isobutene gas;

[0074] Step 7: Add 5 kg of catalyst cation exchange resin to the polymerization kettle;

[0075] Step 8: heat up to 185°C, fully stir and react for 3.6 hours;

[0076] Step 9: remove moisture under reduced pressure, unreacted n-butanol;

[0077] Step ten: remove the cation...

Embodiment 3

[0085] 3# Minimal quantity lubricating oil

[0086] Step 1: Put 138.21kg (3000mol) of ethanol and 116.07kg (1000mol) of maleic acid into the polymerization kettle respectively, and fully stir;

[0087] Step 2: Put 0.51kg initiator diethylhexyl peroxydicarbonate (EHP) into the polymerization kettle;

[0088] Step 3: Filling with nitrogen to discharge the air in the polymerization kettle;

[0089] Step 4: heat up to 70°C while stirring;

[0090] Step 5: Slowly fill 56.11kg (1000mol) of isobutylene gas into the mixed liquid in the polymerization kettle, and keep stirring at a constant temperature;

[0091] Step 6: Keep stirring at constant temperature for 6 hours after filling the isobutene gas;

[0092] Step 7: Add 3.1 kg of catalyst cation exchange resin to the polymerization kettle;

[0093] Step 8: heat up to 180°C, fully stir and react for 4 hours;

[0094] Step 9: remove moisture and unreacted ethanol under reduced pressure;

[0095] Step ten: remove the cation exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com