Tin brass strip and manufacturing method thereof

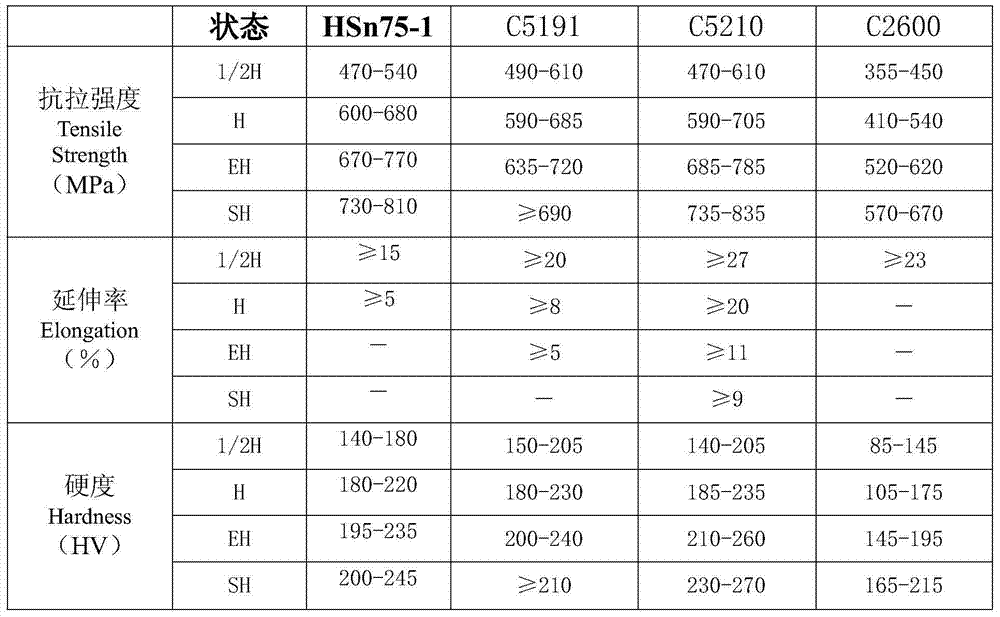

A manufacturing method, tin brass technology, applied in the field of copper alloys, can solve the problems of lack of stress relaxation resistance and stress corrosion cracking resistance, difficulty in meeting connector strength requirements, high price of tin phosphor bronze, etc. Achieve the effect of excellent conductivity, high elasticity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for manufacturing a tin brass strip, comprising the steps of:

[0020] (1) Selection of raw materials: The raw materials are composed of tinned brass scraps, electrolytic copper, H70 brass scraps, and tin bars. Among them, the weight of electrolytic copper and tin bars accounts for 30% of the total weight of raw materials, and the balance is It is H70 brass scrap and tinned brass scrap, and the weight ratio between electrolytic copper, H70 brass scrap and tin bar is 50:55:1. (2) Melting, the temperature of the melting furnace converter is controlled at 1170±15°C; (3) Horizontal continuous casting; casting process: pull 10-15mm, push back one (0-1.6) mm and stop for 2-5 seconds, push back two ( 1-1.8mm), holding furnace drawing control temperature 1075±10℃, slab thickness 16mm, holding furnace liquid level difference less than 20cm, temperature difference of slab end surface controlled below 50℃; (4) milling (5) Winding (14.5→13.0mm); (6) First annealing; (7) R...

Embodiment 2

[0026] A method for manufacturing a tin brass strip, comprising the steps of:

[0027](1) Selection of raw materials: The raw materials are composed of tinned brass scraps, electrolytic copper, H70 brass scraps, and tin bars. Among them, the weight of electrolytic copper and tin bars accounts for 25% of the total weight of raw materials, and the balance is It is H70 brass scrap and tinned brass scrap, and the weight ratio between electrolytic copper, H70 brass scrap and tin bar is 50:55:1. (2) Melting, melting furnace converter control temperature 1180±15°C; (3) Horizontal continuous casting; casting process: pull 10-15mm, push back one (0-1.6) mm and stop for 2-5 seconds, push back two (1) -1.8mm), holding furnace drawing control temperature 1080±10°C, slab thickness 16mm, holding furnace liquid level difference less than 20 cm, and casting slab end face temperature difference below 50°C; (4) Face milling , milling off 0.7-0.8mm on the upper and lower sides; (5) coiling (14....

Embodiment 3

[0033] A method for manufacturing a tin brass strip, comprising the steps of:

[0034] (1) Selection of raw materials: The raw materials are composed of tinned brass scraps, electrolytic copper, H70 brass scraps, and tin bars. Among them, the weight of electrolytic copper and tin bars accounts for 22% of the total weight of raw materials, and the balance is It is H70 brass scrap and tinned brass scrap, and the weight ratio between electrolytic copper, H70 brass scrap and tin bar is 50:55:1. (2) Melting, melting furnace converter control temperature 1185±15°C; (3) Horizontal continuous casting; casting process: pull 10-15mm, push back one (0-1.6) mm and stop for 2-5 seconds, push back two (1) -1.8mm), holding furnace drawing control temperature 1085±10°C, slab thickness 16mm, holding furnace liquid level difference is controlled at less than 20 cm, and the temperature difference at the end face of the slab is controlled below 50°C; (4) Face milling , milling off 0.7-0.8mm on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com